Clean fracturing fluid and preparing method thereof

A technology for cleaning fracturing fluid and fracturing fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost and high concentration, and achieve increased viscosity, high consistency and viscoelasticity, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

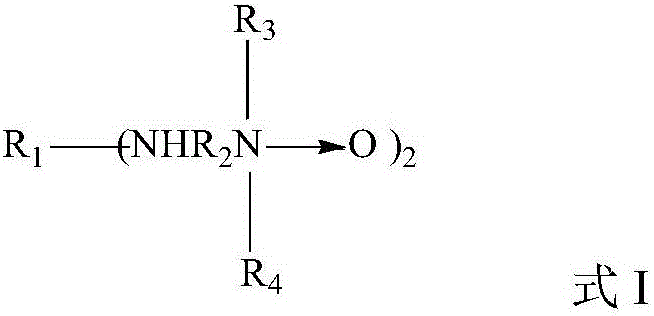

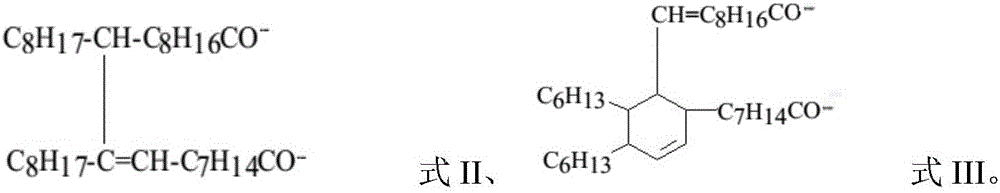

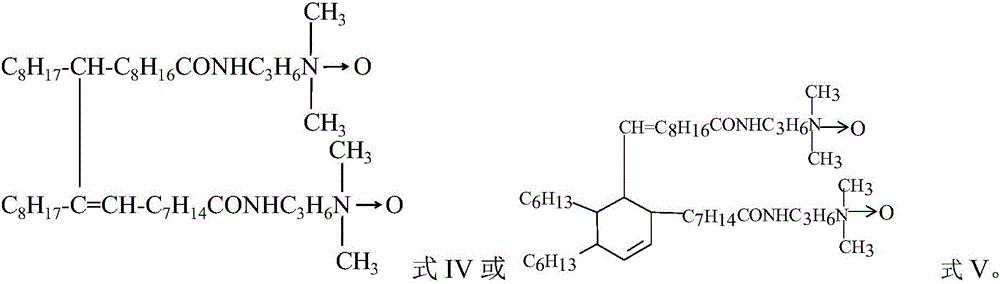

Method used

Image

Examples

Embodiment 1

[0040] The present embodiment provides a kind of preparation method of cleaning fracturing fluid, and it comprises the following steps:

[0041] 1) Synthesis of Dipolyoctadecylamide

[0042] Take 100 g of high-purity dimer acid (dimer octadecanoic acid with a carbon number of C36>95%) and add it to N,N-dimethyl-1,3-propylenediamine (38.3 g, 0.38 mol), After mixing evenly, heat to 160-180°C, keep it warm for 3-8 hours, distill off the water generated by the reaction, and the reaction ends when the acid value is less than 6; distill to remove excess N,N-dimethyl-1,3-propane Diamine, to obtain high-purity dimer octadecylamide.

[0043] 2) Synthesis of Dipolyamidopropylamine Oxide Surfactant

[0044] Add 10.3 g of 30% concentration of hydrogen peroxide into 27 mL of water and 12 g of dipropylene glycol, mix and heat to 70-80° C., then add 20 g of high-purity dioctadecylamide obtained in step 1), at 60-80 Reaction at ℃, when the reaction process reaches 98% of the theoretical va...

Embodiment 2

[0053] Present embodiment is on Haake RS6000 rheometer, in 100s -1 Under the shear rate, the viscosities of the liquids with different compositions were tested for viscosity at 70° C., and the results are shown in Table 1 (concentration is the weight ratio of the active substance content).

[0054] Table 1 Viscosity test results

[0055]

[0056]

[0057] It can be seen from Table 1 that in different series of homogeneous liquids, the viscosity obtained after compounding the dipolyamide-containing amine oxide surfactant and the anionic polymer containing a hydrophobic group is higher than the viscosity when the two are used alone times, higher than single-chain amine oxide.

Embodiment 3

[0059] In this embodiment, the dynamic viscoelasticity of the composite sample containing HMPAM and surfactant in Example 2 was tested on a Haake Mars rheometer, and the results are shown in Table 2.

[0060] Table 2 Viscoelastic properties (60°C, 0.01rad / s)

[0061] Composition, by weight percent G' (storage modulus), Pa G” (loss modulus), Pa 0.25%HMPAM+0.2%DIAMO 0.52 0.21

[0062] It can be seen from Table 2 that when the frequency of the composite sample is very low (0.1rad / s), G' (storage modulus) is greater than G" (loss modulus), indicating that it has high viscoelastic properties. The sand-carrying performance is favorable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com