A kind of light vehicle manual transmission oil and preparation method thereof

A transmission oil and driver technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor adaptability of thermally stable sealing materials, lack of uniform specifications for manual transmission oil, poor low temperature performance and storage stability, etc. Achieve the effect of good storage stability, good adaptability and good low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

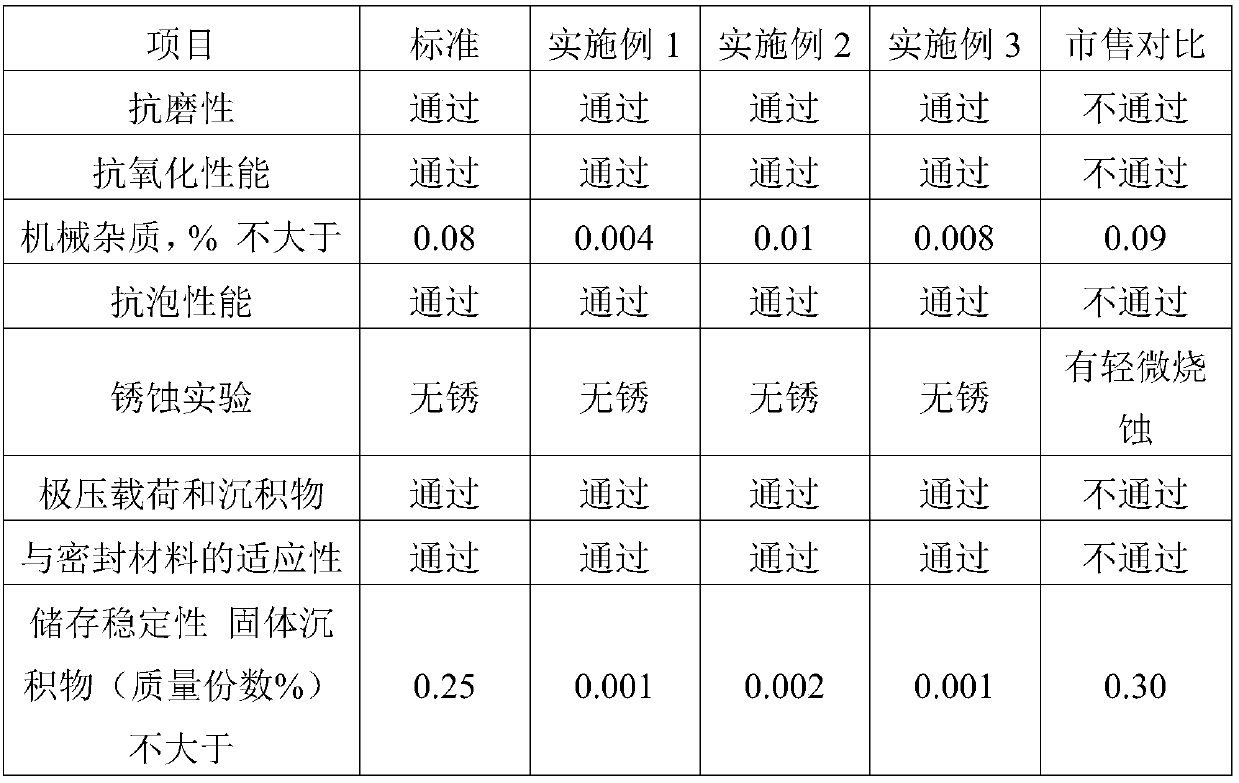

Examples

Embodiment 1

[0022] A light-duty vehicle manual transmission oil, comprising the following components by weight: 30 parts of base oil, 5 parts of glycerin, 8 parts of sulfide compounds, 4 parts of polycarboxylic acid, 3 parts of metal deactivator, cleaning and dispersing agent 3 parts, friction modifier 2 parts, antifoaming agent 3 parts, antioxidant 5 parts, rust inhibitor 3 parts, anti-emulsifier 3 parts, deionized water 30 parts.

[0023] Wherein, the base oil is composed of mineral base oil and synthetic base oil in a mass ratio of 4:1; the metal deactivator is a mixture of clay and basic compound with a mass of 3:1; the cleaning and dispersing The agent is a mixture of alkyl salicylate and ashless phosphate with a mass ratio of 4:1; the friction modifier is a polyalkylene polyamine-based friction modifier; the antifoaming agent is an acrylate copolymer and Simethicone oil mass ratio is the mixture of 4:1; Described antioxidant is low-temperature antioxidant; Described antirust agent i...

Embodiment 2

[0030] A light-duty vehicle manual transmission oil, comprising the following components by weight: 40 parts of base oil, 10 parts of glycerin, 12 parts of sulfide compounds, 8 parts of polycarboxylic acid, 5 parts of metal deactivator, cleaning and dispersing agent 6 parts, 8 parts of friction modifier, 6 parts of antifoaming agent, 8 parts of antioxidant, 6 parts of rust inhibitor, 9 parts of anti-emulsifier, 35 parts of deionized water.

[0031] Wherein, the base oil is composed of mineral base oil and synthetic base oil in a mass ratio of 4:1; the metal deactivator is a mixture of clay and basic compound with a mass of 3:1; the cleaning and dispersing The agent is a mixture of naphthenate and ashless phosphate in a mass ratio of 4:1; the friction modifier is a polyalkylene polyamine-based friction modifier; the antifoaming agent is an acrylate copolymer and two The methyl silicone oil mass ratio is a mixture of 4:1; the antioxidant is a low-temperature antioxidant; the rus...

Embodiment 3

[0038] A light-duty vehicle manual transmission oil, comprising the following components by weight: 35 parts of base oil, 7 parts of glycerin, 10 parts of sulfide compounds, 6 parts of polycarboxylic acid, 4 parts of metal deactivator, cleaning and dispersing agent 5 parts, 5 parts of friction modifier, 5 parts of antifoaming agent, 7 parts of antioxidant, 5 parts of rust inhibitor, 3-9 parts of anti-emulsifier, 33 parts of deionized water.

[0039] Wherein, the base oil is composed of mineral base oil and synthetic base oil in a mass ratio of 4:1; the metal deactivator is a mixture of clay and basic compound with a mass of 3:1; the cleaning and dispersing The agent is a mixture of alkyl salicylate and ashless phosphate with a mass ratio of 4:1; the friction modifier is a polyalkylene polyamine-based friction modifier; the antifoaming agent is an acrylate copolymer and Simethicone oil mass ratio is the mixture of 4:1; Described antioxidant is low-temperature antioxidant; Descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com