Necking apparatus and method for growing seed crystal by horizontal gradient condensing of monocrystal

A horizontal gradient, seed crystal technology, applied in the direction of single crystal growth, crystal growth, self-solidification method, etc., can solve the problems of inability to manufacture optical and electronic devices, reducing the crystallization rate of single crystal growth, waste of manpower, material resources and energy, etc. Achieve the effect of eliminating hereditary defects, eliminating surface defects, and improving crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

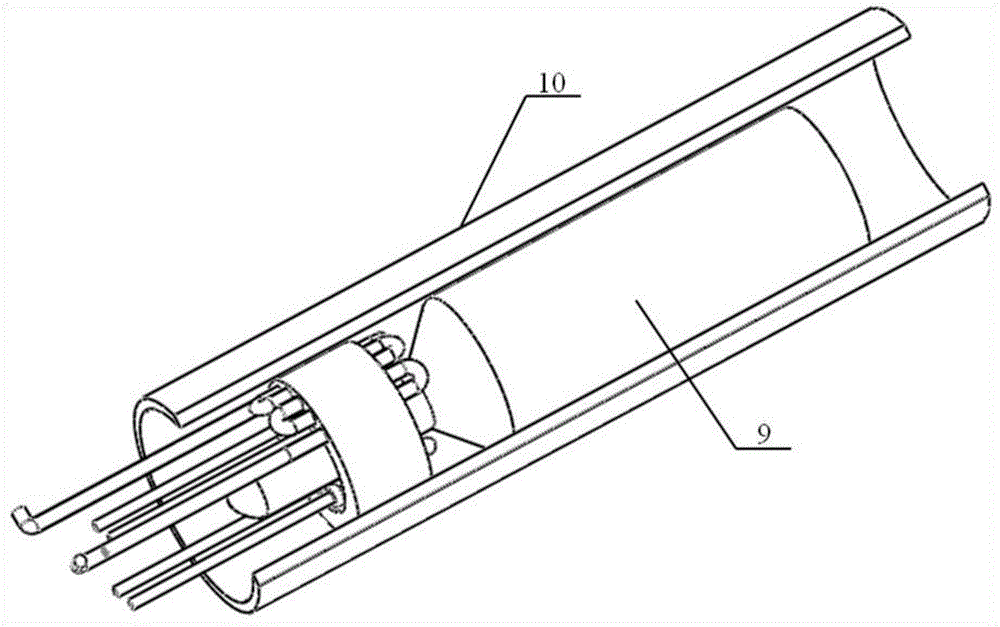

[0049] (1) Furnace loading, such as image 3 Shown: The horizontal gradient condensation growth furnace is placed horizontally, and the sealed growth material tube and the necking device are installed in sequence. The coaxial ring support member of the necking device surrounds the periphery of the seed crystal bag, and the seed crystal bag and the growth material The intersection of the tubes and the side of the coaxial ring support member facing the furnace are on the same longitudinal plane, and the two free ends of the curved heating member extend to the outside of the horizontal gradient condensation growth furnace and are connected to the heating wire of the thyristor control power supply; temperature monitoring The ends of the four thermocouples of the component extend out of the horizontal gradient condensation growth furnace and connect with the thermocouple compensation line of the temperature monitor;

[0050] (2) Melt material: the horizontal gradient condensation g...

Embodiment 2

[0057] (1) Furnace loading, such as image 3 As shown: the horizontal gradient condensation growth furnace is placed horizontally, and the sealed growth material tube, seed crystal bag and necking device are loaded in sequence. The coaxial ring support member of the necking device surrounds the periphery of the seed crystal bag, and the seed crystal The intersection of the bag and the growth material tube is on the same longitudinal plane as the coaxial ring support member facing the furnace, and the two free ends of the curved heating member extend to the outside of the horizontal gradient condensation growth furnace and connect with the silicon controlled silicon control power supply heating wire connected; the ends of the four thermocouples of the temperature monitoring component extend out of the horizontal gradient condensation growth furnace and are connected with the thermocouple compensation lines of the temperature monitor;

[0058] (2) Melt material: the horizontal g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com