Two-dimensional material flexible substrate structure, focal plane optical detector array and manufacturing method thereof

A flexible substrate, two-dimensional material technology, used in semiconductor devices, climate sustainability, final product manufacturing, etc., can solve lattice mismatch, flexible substrates cannot fully absorb and release stress, and cannot meet absolute flexibility and other problems, to achieve the effect of large absolute flexibility, increase device integration function, and reduce device dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

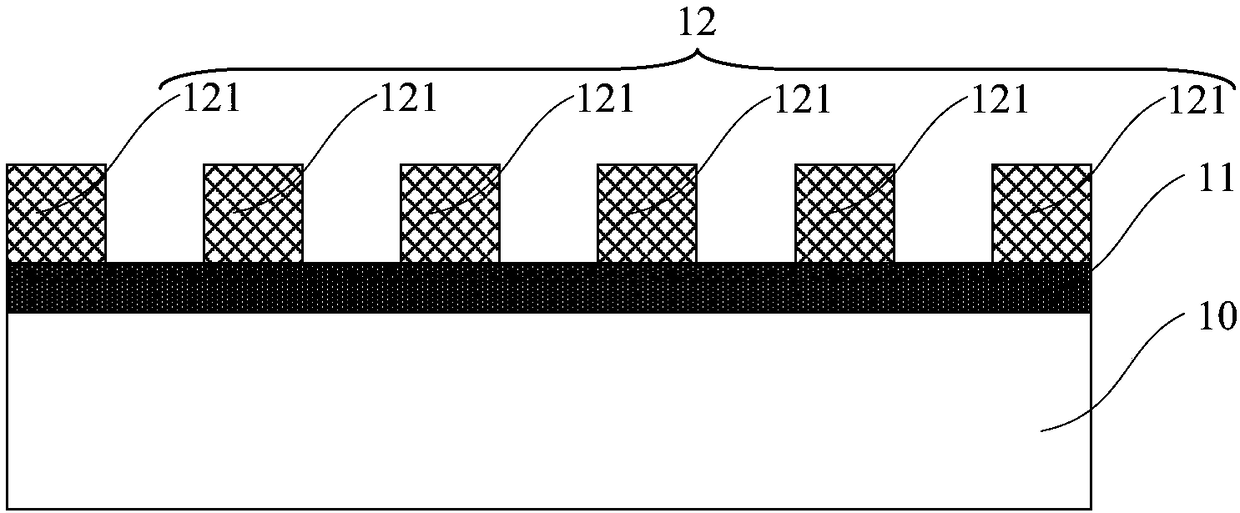

[0075] see figure 1 , the present invention provides a two-dimensional material flexible substrate structure, the two-dimensional material flexible substrate structure includes: a supporting substrate 10; a two-dimensional material layer 11, the two-dimensional material layer 11 is located on the supporting substrate 10 surface; a patterned flexible substrate 12, the patterned flexible substrate 12 is located on the surface of the two-dimensional material layer 11; the patterned flexible substrate 12 includes several pattern units 121 distributed at intervals. The two-dimensional material flexible substrate structure of the present invention combines the patterned flexible substrate 12 with the two-dimensional material layer 11, and the interface between the patterned flexible substrate 12 and the two-dimensional material layer 11 The van der Waals bond greatly weakens the attraction between the upper and lower atoms, and the strength of the van der Waals force formed at the ...

Embodiment 2

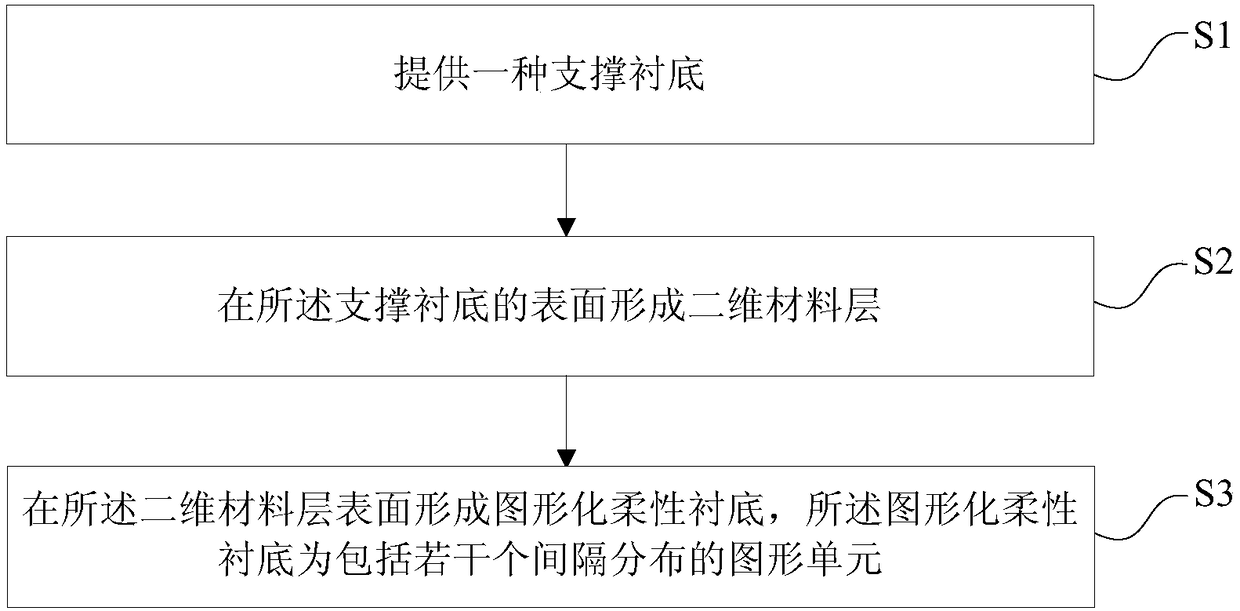

[0084] see figure 2 , the present invention also provides a method for manufacturing a two-dimensional material flexible substrate structure, the method for manufacturing a two-dimensional material flexible substrate structure includes the following steps:

[0085] 1) providing a support substrate;

[0086] 2) forming a two-dimensional material layer on the surface of the supporting substrate;

[0087] 3) A patterned flexible substrate is formed on the surface of the two-dimensional material layer, and the patterned flexible substrate includes several pattern units distributed at intervals.

[0088] To perform step 1), see figure 2 Step S1 in and image 3 , providing a support substrate 10 .

[0089] As an example, the supporting substrate 10 may be a semiconductor substrate, a semi-insulator substrate, an insulator substrate, a thermally conductive material substrate or a metal substrate. Preferably, in this embodiment, the supporting substrate 10 is a Si substrate.

...

Embodiment 3

[0112] see Figure 15 , the present invention also provides a focal plane photodetector array, the focal plane photodetector array includes: the two-dimensional material flexible substrate structure as described in Embodiment 1, the two-dimensional material flexible substrate structure Please refer to Embodiment 1 for the specific structure, which is no longer similar here; the photodetector structure 17, the photodetector structure 17 is located on the surface of each pattern unit 121 in the patterned substrate 12, that is, the photodetector structure 17 is a structure distributed in a periodic array.

[0113] As an example, the photodetector structure 17 may be, but not limited to, include In 0.82 Ga 0.18 2.5 µm photodetector structure with As absorbing layer.

[0114] As an example, the photodetector structure 17 may be a structure of upper and lower electrodes, or a structure of coplanar electrodes.

[0115] As an example, the focal plane photodetector array further in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com