Rotary multi-needlepoints electrostatic spinning device

An electrospinning, multi-needle-tip technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of great influence of diameter, equipment cost, increased complexity, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

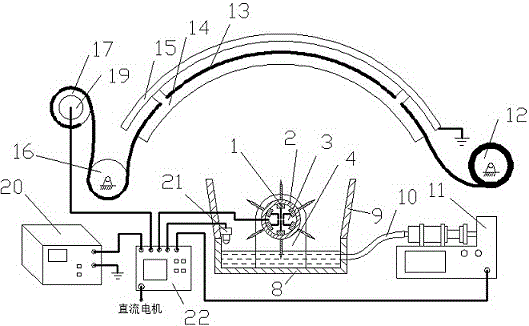

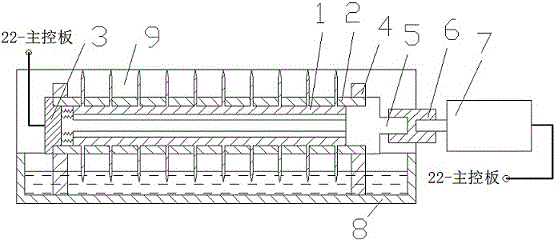

[0014] exist figure 1Among them, the needle point group (1) is fixedly connected with the sleeve (2), and the needle point protrudes from the outer surface of the sleeve (2) as a nozzle, and the needle point group (1) has a total of 6 sets of circumferences evenly on the sleeve (2); the electrode plate (3) Cooperate with one end of the sleeve (2), and the electrode plate (3) is designed with power supply lines, which are respectively connected to 6 sets of needle tip groups (1), and each set of lines is isolated from each other; the electrode plate (3) is designed with a lead The circuit is connected with the main control board (22) to realize independent power supply among different needle point groups (1); the liquid tank (8) is arranged directly under the sleeve (2) and is filled with spinning solution, and the liquid tank (22) has two The backflow plate (9) is installed on the side. When the DC motor (7) drives the sleeve (2) to rotate, the array of needle point groups (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com