Heat dissipation unit system of ceramic substrate of thick-film circuit chip applied to heat supply

A technology based on ceramic substrates and thick film circuits. It is applied in the direction of electric heating devices, electrical components, and ohmic resistance heating. It can solve the problems of wasting power resources, shortage of supply, and tight power supply in cities. It achieves dispersed heat dissipation power density, simple structure, and strong The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

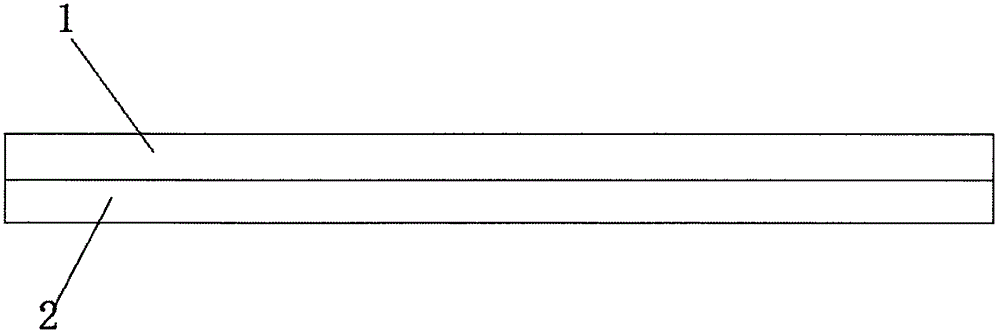

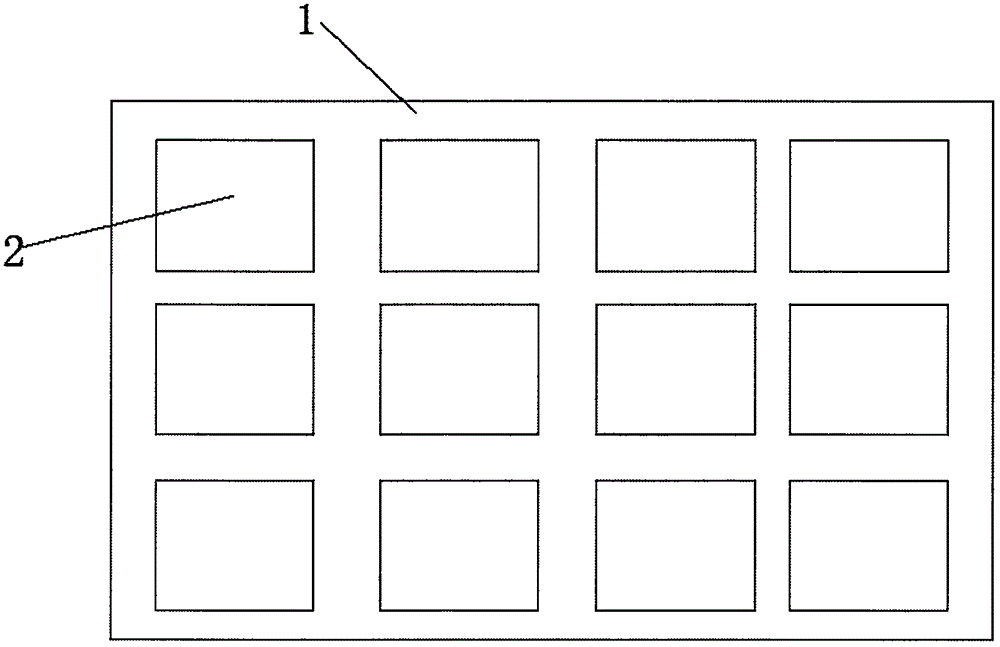

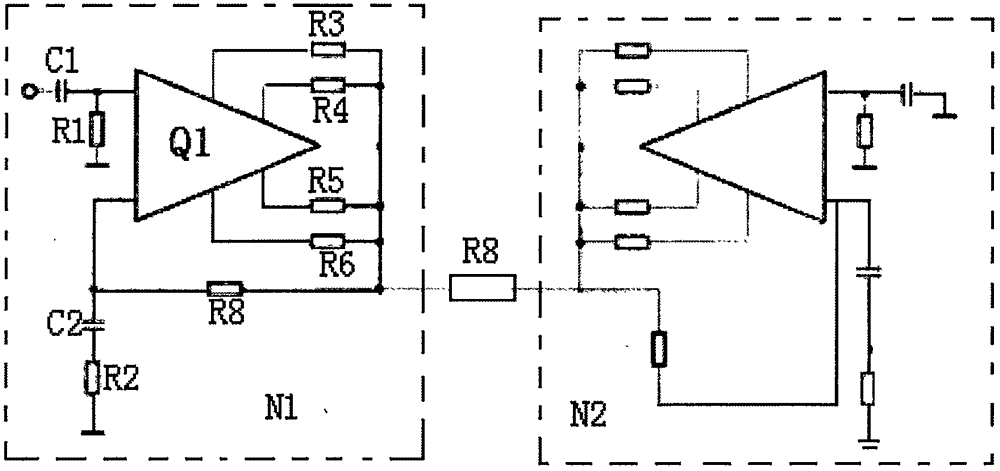

[0019] Such as figure 1 and combine figure 2 and image 3 As shown, a thick-film circuit chip ceramic substrate cooling unit system for heating includes a ceramic substrate 1 and a thick-film circuit chip 2, and the back-film circuit chip 1 is sintered on the substrate by vacuum evaporation or magnetron sputtering. On the ceramic substrate 2, the ceramic substrate 1 adopts alumina ceramics with heat dissipation function or rare earth ceramics with far-infrared function, and the rear membrane circuit chip 2 includes a rear membrane circuit and a control chip. The control chip is connected, the thickness of the film circuit is greater than 10um, and the rare earth ceramic is made of beryllium oxide ceramic material.

[0020] Further, the rear film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com