Demister for desulfurization tower

A technology of desulfurization tower and demister, which is applied in the field of flue gas desulfurization, can solve the problems of affecting the use effect of the downstream ridge type demister, the blockage of the demister, the flow velocity distribution of the smoke, and the inability to meet the national environmental protection requirements, so as to reduce the blockage Excellent corrosion resistance, corrosion resistance and pitting resistance, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

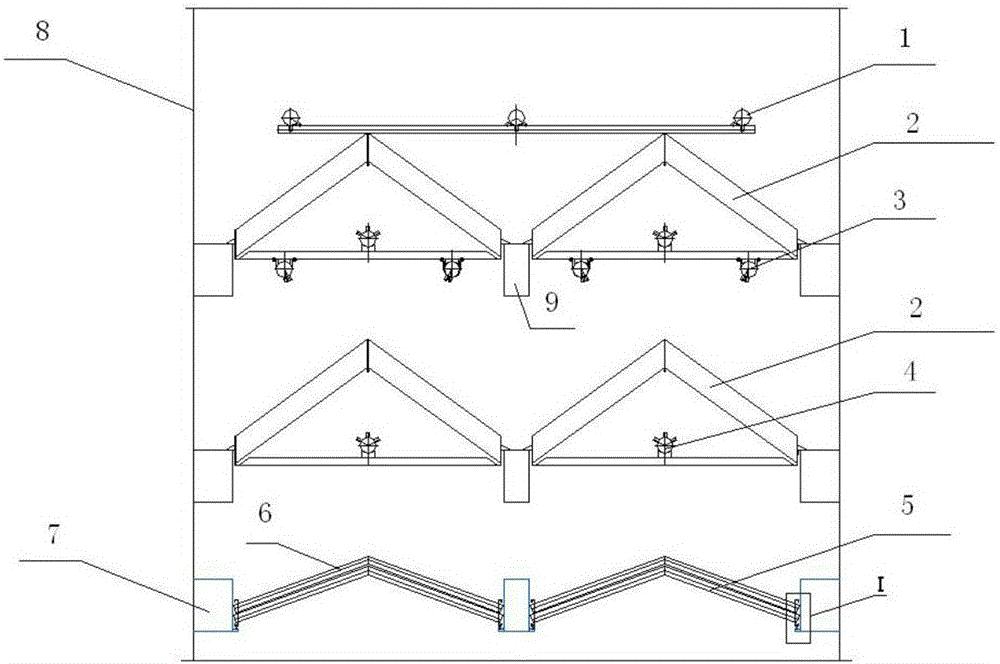

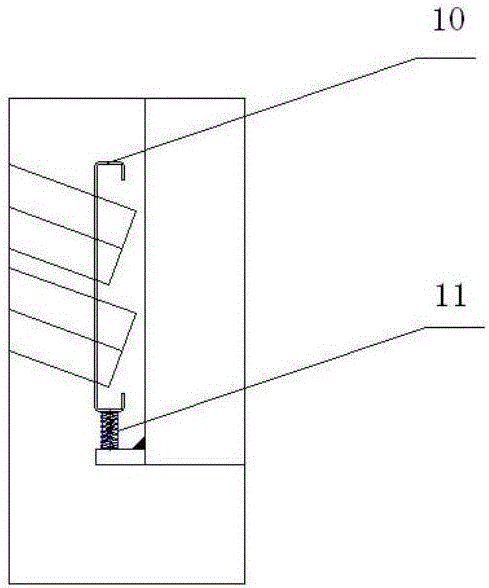

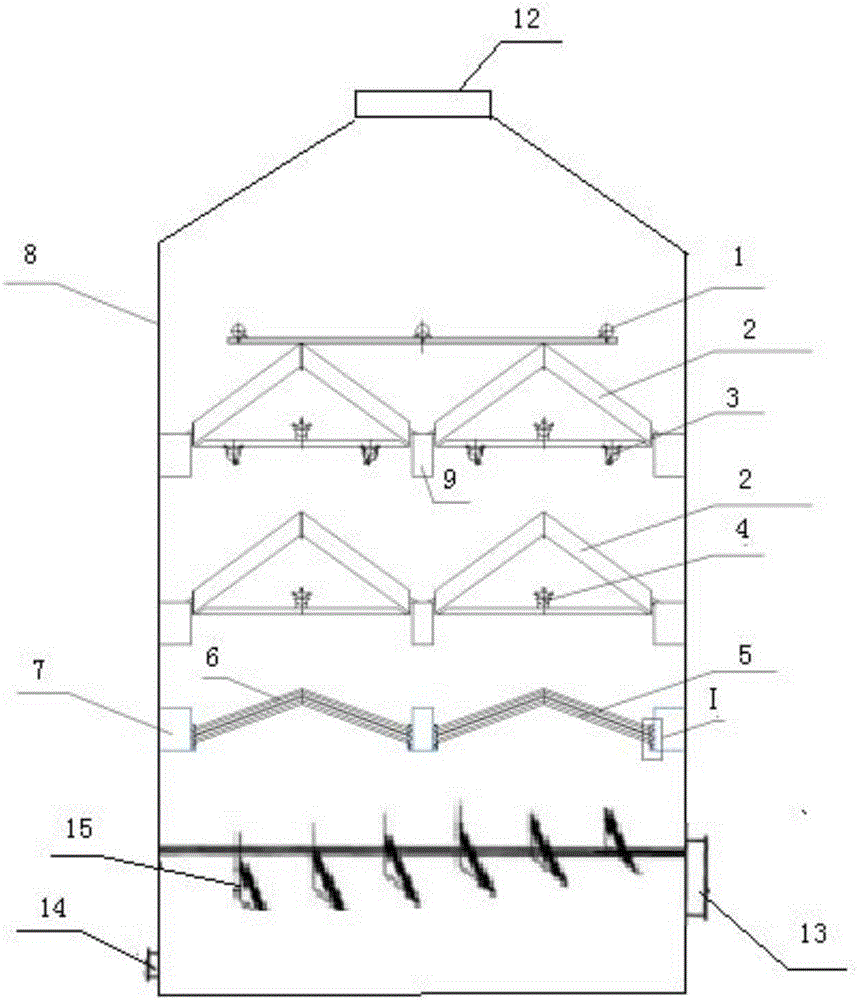

[0028] Such as figure 1 with 3 As shown, the desulfurization tower includes a desulfurization tower body 8. Below the desulfurization tower body 8 is provided an air inlet 13 and a circulating water discharge port 14, and the top is provided with an air outlet 12. The air inlet 13 and the circulating water discharge port 14 are located in the desulfurization tower body. 8 on both sides. The inner wall of the desulfurization tower body 8 is provided with three rows of equal-height supports 7. The wave baffle is arranged on the support 7. The wave baffle includes a wave baffle tube 5 arranged transversely above the air inlet 12 and a wave baffle plate 2 transversely arranged below the air outlet.

[0029] The wave baffle 2 includes an upper and a lower baffle unit; the baffle unit includes at least two rows of demisting modules with a herringbone cross section, and a rectangular parallelepiped supporting column 9 is arranged between each row of the demisting modules. Each column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com