Gas-liquid-solid stirring device

A stirring device, gas-liquid-solid technology, applied in mixers with rotary stirring devices, mixer accessories, transportation and packaging, etc., can solve the problem of reducing the reaction efficiency of gas and liquid, easy gas escape, and difficulty in uniform and large stirring. Control and other issues to achieve the effect of improving gas reaction efficiency, prolonging reaction time, and increasing projection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

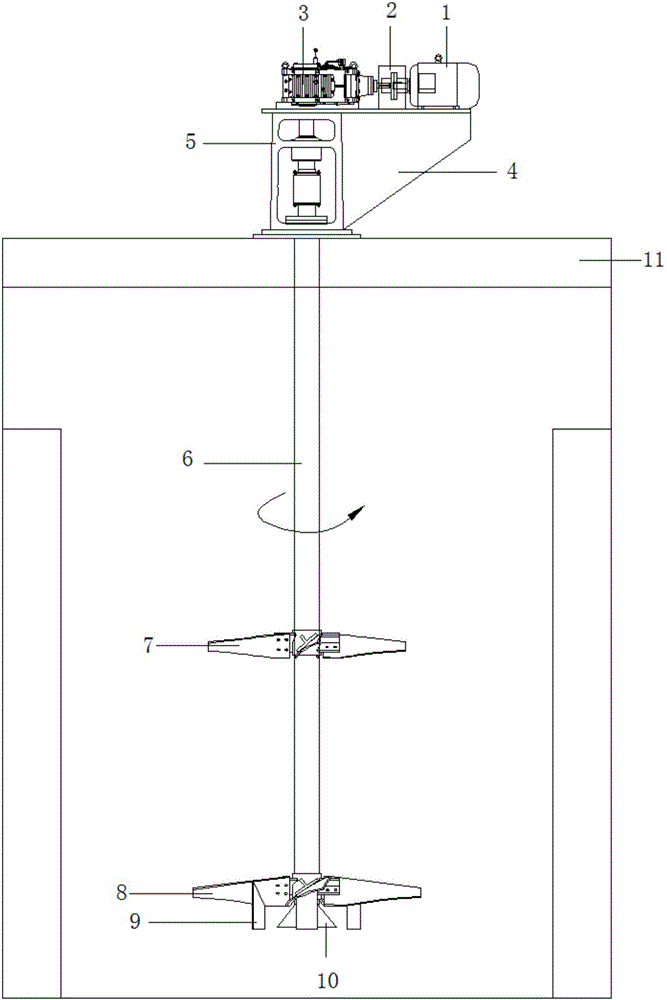

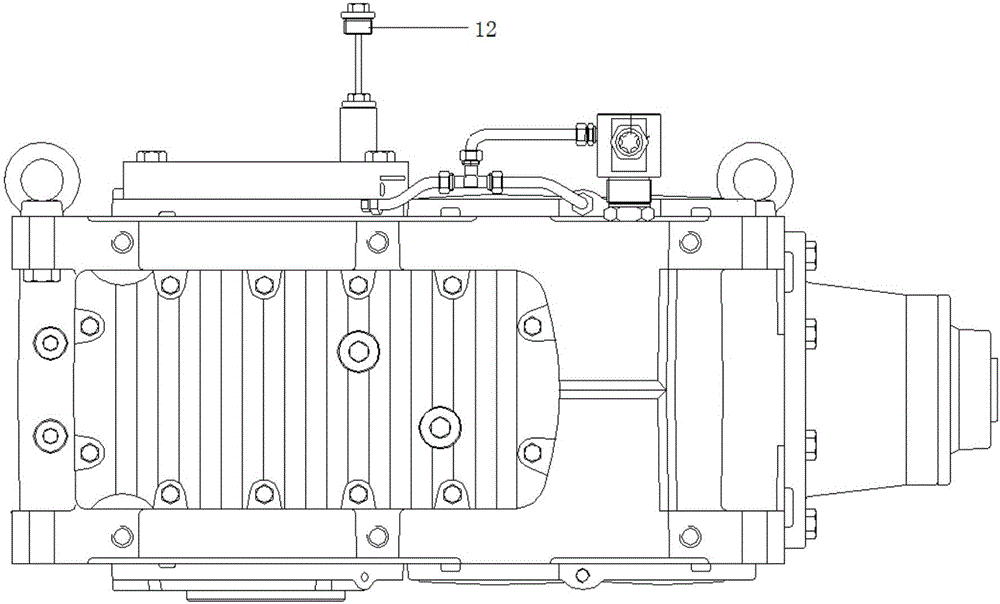

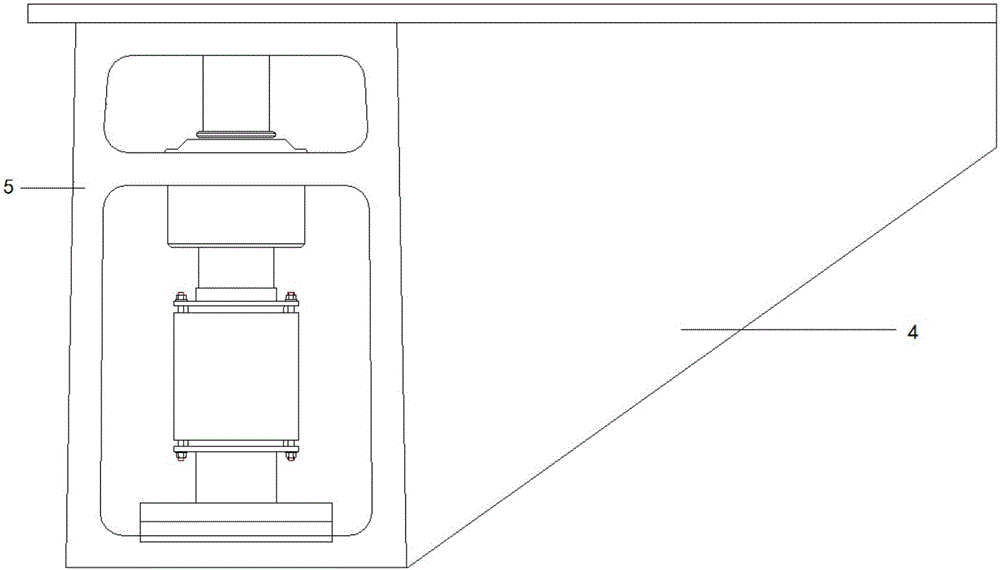

[0026] Such as Figure 1-3 As shown, a gas-liquid-solid mixing device provided by the present invention includes a driving part, a frame, and a mixing mechanism arranged in sequence, and is characterized in that the mixing mechanism consists of a mixing barrel 11 and a mixing blade with paddles on its axis. The drive is composed of a shaft 6. The driving part includes an electric motor 1, a coupling 2 and a reducer 3 arranged in sequence along the same horizontal axis. An air outlet 12 is provided above the reducer 3, and the reducer 3 is a gear reducer, Worm gear reducer and / or pulley reducer, the frame is composed of a trapezoidal rib 4 for installing the electric motor 1 and a rectangular frame 5 for installing the reducer 3, and the mixing barrel 11 is a cylinder Body, the top is provided with a circular through hole connected to the stirring shaft 6, the top of the stirring shaft 6 is connected to the reducer 3, the bottom end is not connected to the bottom of the stirring ...

Embodiment 2

[0029] When the stirring device is working, the motor 1 is started, and the reducer 3 is driven by the coupling 2 to rotate, and the reducer 3 drives the stirring shaft 6 to rotate at the same time. When the stirring shaft 6 rotates, the stirring shaft 6, the air outlet 12 and the air pipe The raw material gas is sucked into the gas hood 10, so that the gas is evenly and slowly dispersed into the liquid to participate in the reaction, and the gas reaction efficiency is improved; at the same time, the second blade 7 is used to stir and rotate at a high speed to form a negative pressure vortex. The reacted gas is sucked into the liquid, and then undergoes gas-liquid absorption and mass transfer. The gas material further increases the reaction speed with the liquid under the action of stirring.

[0030] The nozzle port with elastic self-closing jet function is open when the gas is supplied because the internal pressure is higher than the external pressure, and the gas is discharged; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com