Arc pressure distribution measuring device and method based on graph phase centered short-time arcing

An arc pressure and measuring device technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of inability to accurately measure the distance from the arc pressure distribution, the deformation of the electrode plate hole, etc., to achieve accurate measurement results and reduce guide The effect of hole deformation and maintaining measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

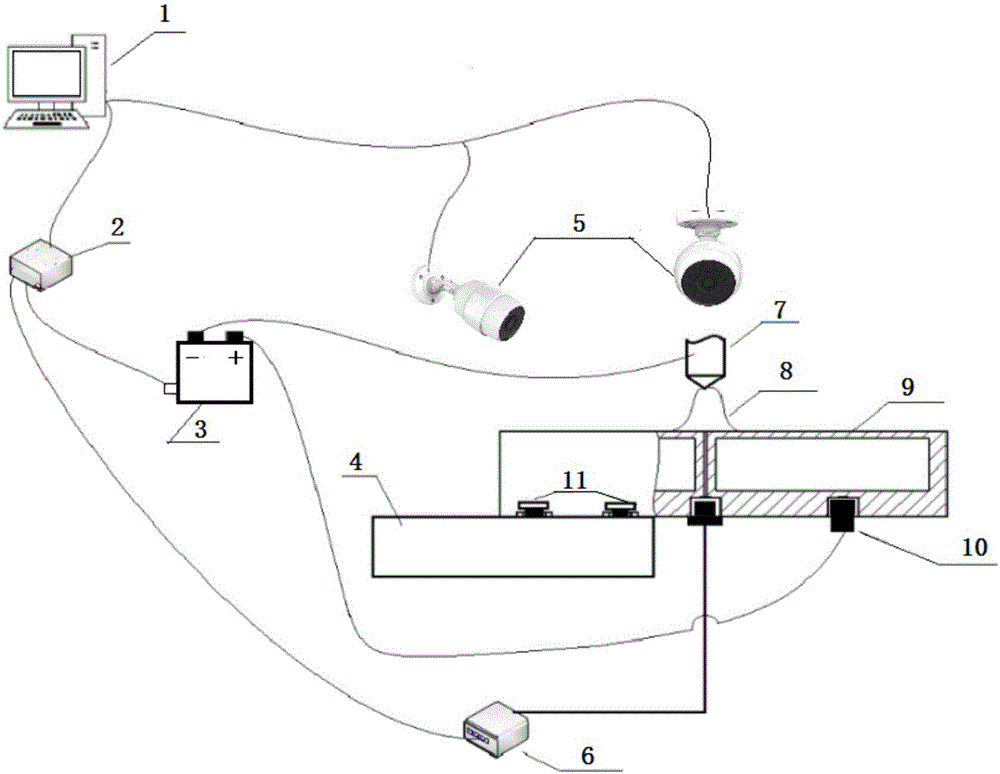

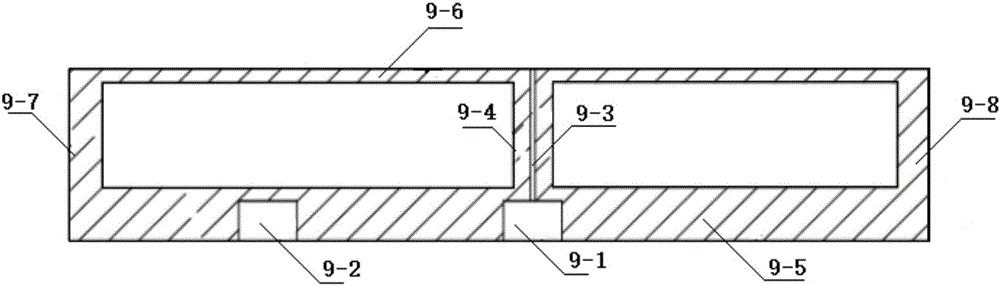

[0027] Such as figure 1 As shown, this embodiment discloses a device for measuring arc pressure distribution based on graph relative short-term arc starting, including a computer system 1, a data acquisition controller (DAQ) 2, a controllable welding power source 3, and a high-precision manual translation platform 4. Camera 5, pressure sensor 6, welding torch 7, water-cooled plate 9, electrode 10. Among them, the data acquisition controller (DAQ) 2 adopts the NI USB-6002 type; the high-precision manual translation stage 4 adopts the PP160-25H type, and its table size is 110m*80mm. The stroke is 25mm, the minimum scale is 0.01mm, the minimum adjustment is 2μmm, the guide rail is a high-precision ultra-thin linear slide rail, the load is 20kg,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com