Mechanical and electrical integrated glassware shaping production line

A glassware and production line technology, applied in the field of electromechanical integrated glassware forming production line, can solve the problems of low production efficiency, large energy waste, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

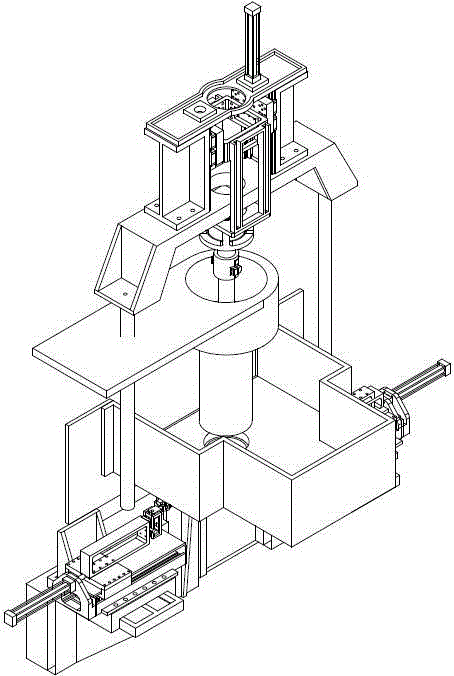

[0097] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings

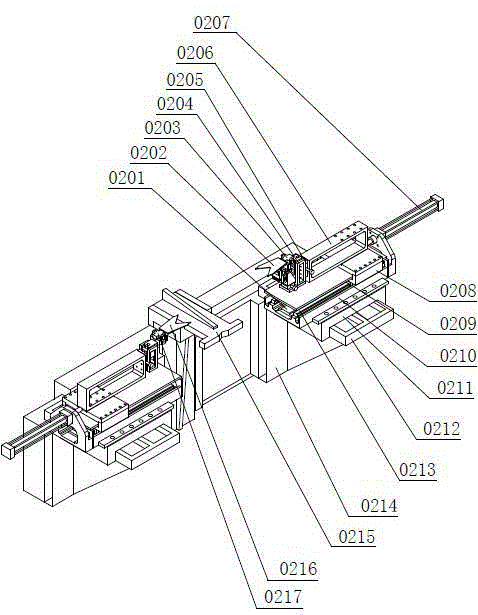

[0098] 1. As shown in the figure: 1~30. A mechanical and electrical integrated glassware automatic forming line: including punch mechanism, scissors mechanism, zero station machine, forming machine, unloading device, material receiving device and delivery device, conveying device , the control device, and the sensor device are respectively connected to the punch mechanism, the scissors mechanism, the 0-position machine, the molding machine, the unloading device, the material receiving device and the delivery device, and the conveying device is controlled to cooperate with each other.

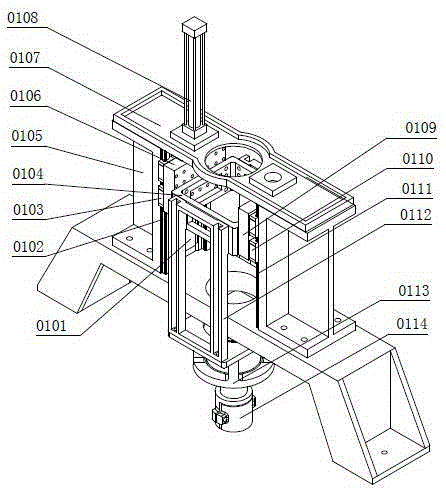

[0099] 1. Glass gob punch mechanism: including a beam, on the upper plane of the beam, the center point of the center hole is the base point, and the two ends are symmetrical and connected to the beam vertically. 2 supports, of which: 1 support 0105 is perpendicular to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com