Efficient fireproof environment-friendly foam plugging material

A sealing material and an environmentally friendly technology, applied in the field of environmentally friendly foam sealing materials, can solve the problems of difficult to meet the difficult requirements of fire protection, endanger life safety, low fire limit, etc., and achieve good sealing effect and fire prevention. High limit and long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

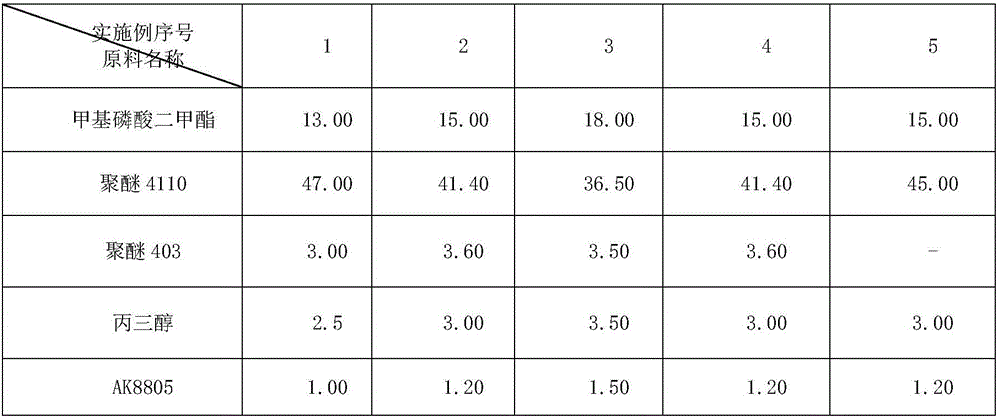

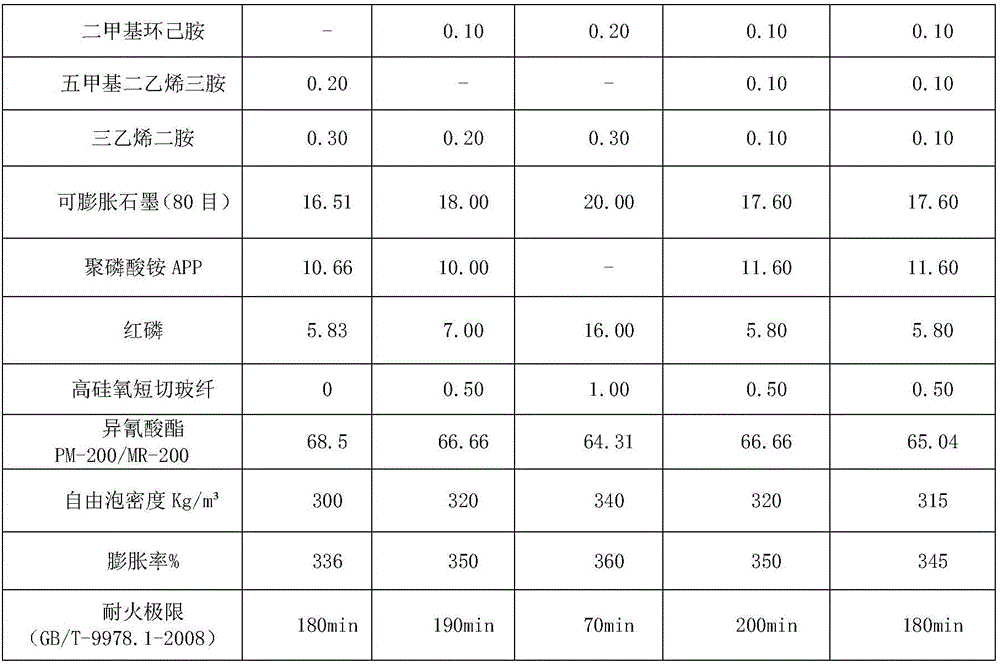

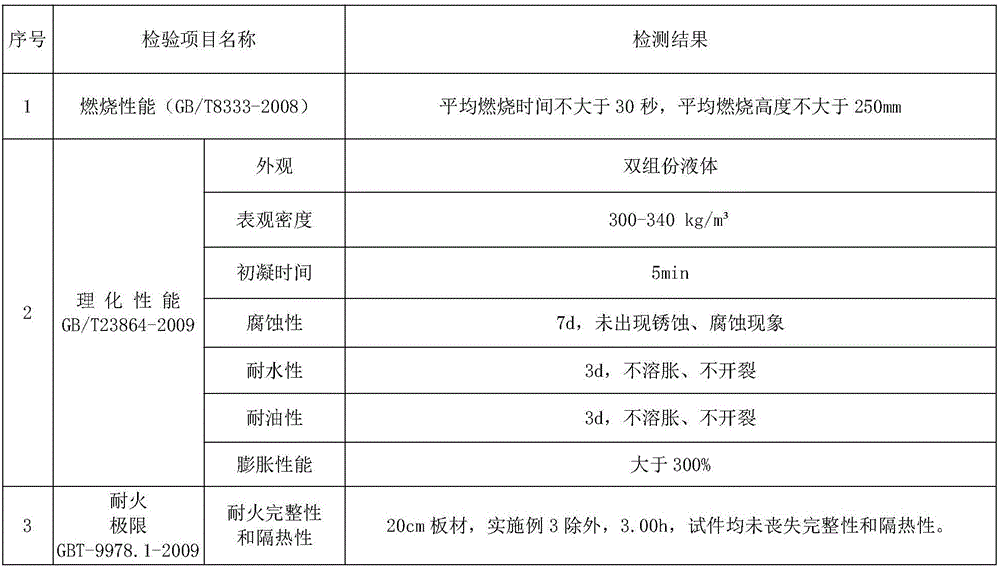

Embodiment 1

[0028] Weigh 13.00g of dimethyl methyl phosphate, 47.00g of rigid foam polyether 4110, 3.00g of rigid foam polyether 403 and 2.50g of glycerol in turn, mix and stir evenly, add 1.00g of AK8805 foam stabilizer, 0.20g of pentamethyl Diethylenetriamine and 0.30g triethylenediamine, after fully dispersed, add 16.51g expandable graphite 80 mesh, 10.66g high polymerization degree ammonium polyphosphate (polymerization degree>1000) and 5.83g microencapsulated red phosphorus, Mix well and stir to obtain component A.

[0029] B component is PM-200 type isocyanate 68.5g.

[0030] After the preparation of component A is completed, component A and component B are mixed and foamed to test the relevant performance indicators.

[0031] Test result: Temperature: 25.5℃ Humidity: 30%RH

[0032] Milky time: 46S Drawing time: 2′30″

[0033] Non-stick time: 3′35″ Free foam density: 300kg / m 3

Embodiment 2

[0035] Weigh 15.00g of dimethyl methyl phosphate, 41.40g of rigid foam polyether 4110, 3.60g of rigid foam polyether 403 and 3.00g of glycerol in turn, mix and stir evenly, add 1.20g of AK8805 foam stabilizer, 0.10g of dimethyl methacrylate Cyclohexylamine and 0.20g triethylenediamine, after fully dispersed, add 18.00g expandable graphite 80 mesh, 10.00g high polymerization degree ammonium polyphosphate (polymerization degree>1000) and 7.00g microencapsulated red phosphorus and mix well , and finally add 0.50g high silica chopped glass fiber (3mm length); stir to obtain A component.

[0036] B component is PM-200 type isocyanate 66.66g.

[0037] After the preparation of component A is completed, component A and component B are mixed and foamed to test the relevant performance indicators.

[0038] Test result: Temperature: 25.7℃ Humidity: 30%RH

[0039] Milky time: 50S Drawing time: 2′45″

[0040] Non-stick time: 3′50″ Free foam density: 320kg / m 3

Embodiment 3

[0042] Weigh 18.00g of dimethyl methyl phosphate, 36.50g of rigid foamed polyether 4110, 3.50g of rigid foamed polyether 403 and 3.50g of glycerol in turn, mix and stir evenly, add 1.50g of AK8805 foam stabilizer, 0.20g of dimethylformaldehyde Cyclohexylamine and 0.30g triethylenediamine, after fully dispersed, add 20.00g expandable graphite 80 mesh and 16.00g microencapsulated red phosphorus, mix well, and finally add 1.00g high silica chopped glass fiber (3mm long); stir to obtain component A.

[0043] B component is PM-200 type isocyanate 64.31g.

[0044] After the preparation of component A is completed, component A and component B are mixed and foamed to detect relevant performance indicators.

[0045] Test result: Temperature: 25.1℃ Humidity: 30%RH

[0046] Milky time: 58S Drawing time: 3′05″

[0047] Non-stick time: 4′18″ Free foam density: 340kg / m 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com