High-fire-resistant rigid polyurethane foam external wall insulation material and preparation method thereof

A technology of polyurethane rigid foam and external wall thermal insulation is applied in the field of external wall thermal insulation materials, which can solve the problems of conflict between fire and flame retardant properties and mechanical properties, and achieve the effects of excellent mechanical properties and high flame retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

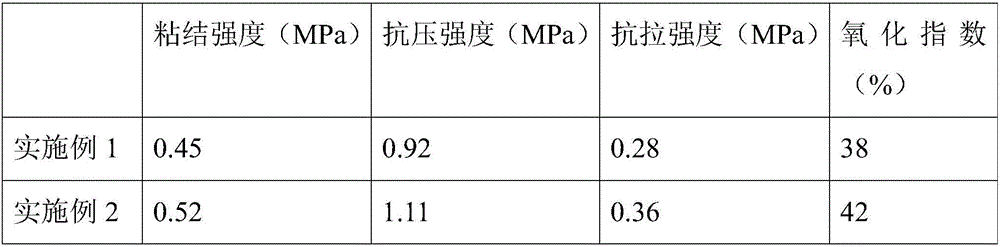

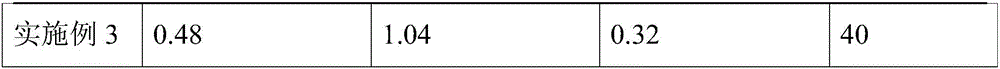

Examples

Embodiment 1

[0021] A highly flame-retardant polyurethane rigid foam external wall insulation material, which consists of component A and component B. Calculated in parts by weight, component A consists of 1 part of chlorinated polypropylene resin, 4 parts of brominated epoxy resin, Composed of 60 parts of polyether polyol, 7 parts of vitrified microspheres, 1 part of dibutyltin laurate, 15 parts of dimethyl methyl phosphate, 1 part of polyether modified organosiloxane and 15 parts of foaming agent, group B Divided into polyphenyl polymethylene polyisocyanate, the foaming agent is composed of 1 part of pentane, 6 parts of pentafluoropentane and 4 parts of dichloroethane. The mixing weight ratio of A component and B component is 1:1.

[0022] The preparation method comprises the following steps: premixing chlorinated polypropylene resin, brominated epoxy resin, polyether polyol, ethylene dichloride and pentafluoropentane, and simultaneously adding vitrified microbeads and polyether modified...

Embodiment 2

[0024] A highly flame-retardant polyurethane rigid foam external wall insulation material, composed of component A and component B, calculated in parts by weight, component A consists of 2 parts of chlorinated polypropylene resin, 10 parts of brominated epoxy resin, 70 parts of polyether polyol, 5 parts of vitrified microspheres, 2 parts of stannous octoate, 24 parts of tris(2-chloroethyl) phosphate, 2 parts of polyether modified organosiloxane and 24 parts of foaming agent , Component B is polyphenyl polymethylene polyisocyanate, and the blowing agent is composed of 3 parts of pentane, 9 parts of pentafluoropentane and 2 parts of dichloroethane. The mixing weight ratio of component A and component B is 1:1.4.

[0025] The preparation method comprises the following steps: premixing chlorinated polypropylene resin, brominated epoxy resin, polyether polyol, ethylene dichloride and pentafluoropentane, and simultaneously adding vitrified microbeads and polyether modified silicone ...

Embodiment 3

[0027] A highly flame-retardant polyurethane rigid foam external wall insulation material, which consists of component A and component B. Calculated in parts by weight, component A consists of 4 parts of chlorinated polypropylene resin, 16 parts of brominated epoxy resin, Composed of 80 parts of polyether polyol, 10 parts of vitrified microspheres, 4 parts of dioctyltin diacetate, 30 parts of tribromoneopentyl alcohol, 3 parts of polyether modified organosiloxane and 30 parts of foaming agent, component B It is polyphenyl polymethylene polyisocyanate, and the foaming agent is composed of 5 parts of pentane, 12 parts of pentafluoropentane and 6 parts of dichloroethane. The mixing weight ratio of component A to component B is 1:1.8.

[0028] The preparation method comprises the following steps: premixing chlorinated polypropylene resin, brominated epoxy resin, polyether polyol, ethylene dichloride and pentafluoropentane, and simultaneously adding vitrified microbeads and polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com