Modified phenyl organosilicone composition for LED packaging

A phenyl silicone, LED packaging technology, used in adhesive additives, non-polymer adhesive additives, electrical components, etc. and other problems to achieve the effect of improving mechanical properties, maintaining high and low temperature resistance, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment relates to a modified phenyl silicone composition for LED packaging, specifically as follows:

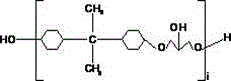

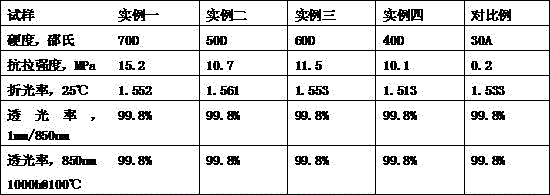

[0031] 100 parts of component one, its Si-OH content is 0.2%, add 10 parts of polyols such as structural formula 4, 1 part of polyols of structural formula 1, 0.01 g of aluminum acetylacetonate in component five, stir and mix evenly, and then add 0.1 gram Pt content is the complex compound of 2%, stir evenly, add component two 6 grams, stir evenly and defoam to form encapsulating material. Curing at 150°C for 4 hours, measuring hardness, tensile strength, refractive index, light transmittance, and light transmittance at 100°C for 1000 hours.

Embodiment 2

[0033] This embodiment relates to a modified phenyl silicone composition for LED packaging, specifically as follows:

[0034] 100 parts of component one, whose Si-OH content is 0.1%, add 15 parts of polyols such as structural formula 3 in component five, 0.01 g of aluminum acetylacetonate, stir and mix evenly, and then add 0.1 g of Pt content of 2%. Compound, stir evenly, add 6 grams of component two, stir evenly and defoam to form an encapsulation material. Curing at 150°C for 4 hours, measuring hardness, tensile strength, refractive index, light transmittance, and light transmittance at 100°C for 1000 hours.

Embodiment 3

[0036] This embodiment relates to a modified phenyl silicone composition for LED packaging, specifically as follows:

[0037] 100 parts of component 1, its Si-OH content is 0.12%, add 8 parts of polyol of structural formula 4 and 1 part of polyol of structural formula 1, 0.02 g of tetraisopropanol titanate in component 5, stir and mix well , then add 0.1 gram of a complex compound with a Pt content of 2%, stir evenly, add 5 grams of component two, stir evenly to degas the encapsulation material. Curing at 150°C for 4 hours, measuring hardness, tensile strength, refractive index, light transmittance, and light transmittance at 100°C for 1000 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com