Compact type vacuum reaction device for chemical vapor deposition (CVD) diamond film

A chemical vapor deposition, diamond film technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of CVD diamond film deposition, etc., to shorten the furnace cooling time, ensure concentricity, circulation reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

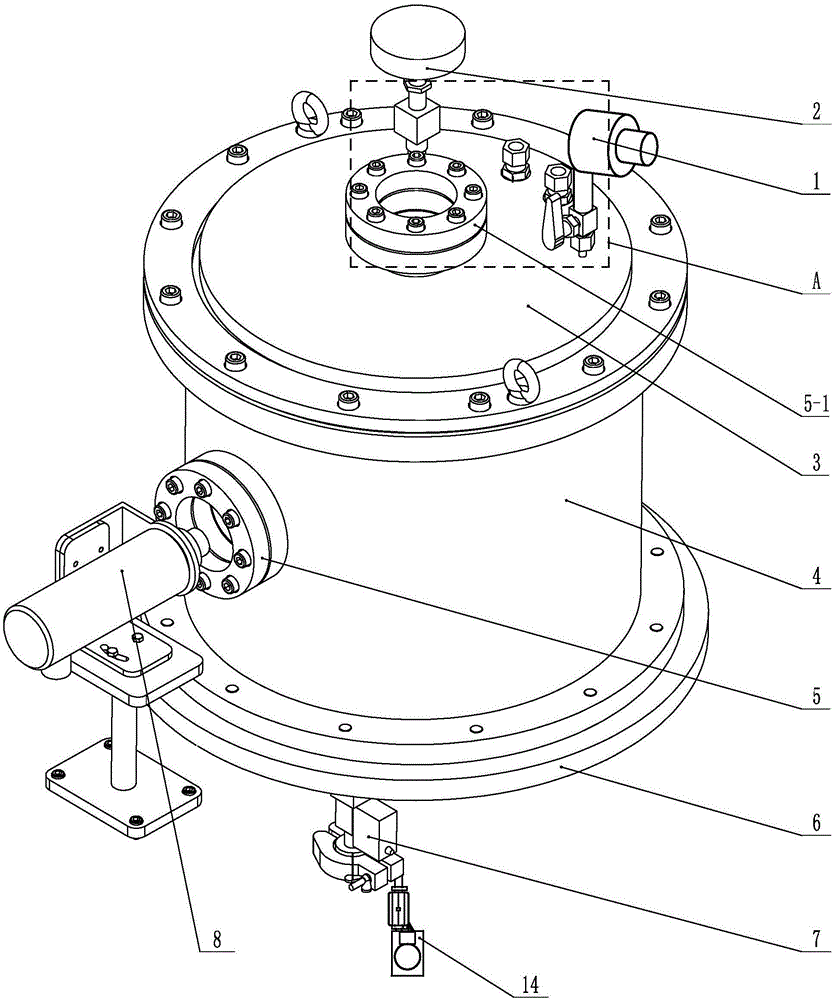

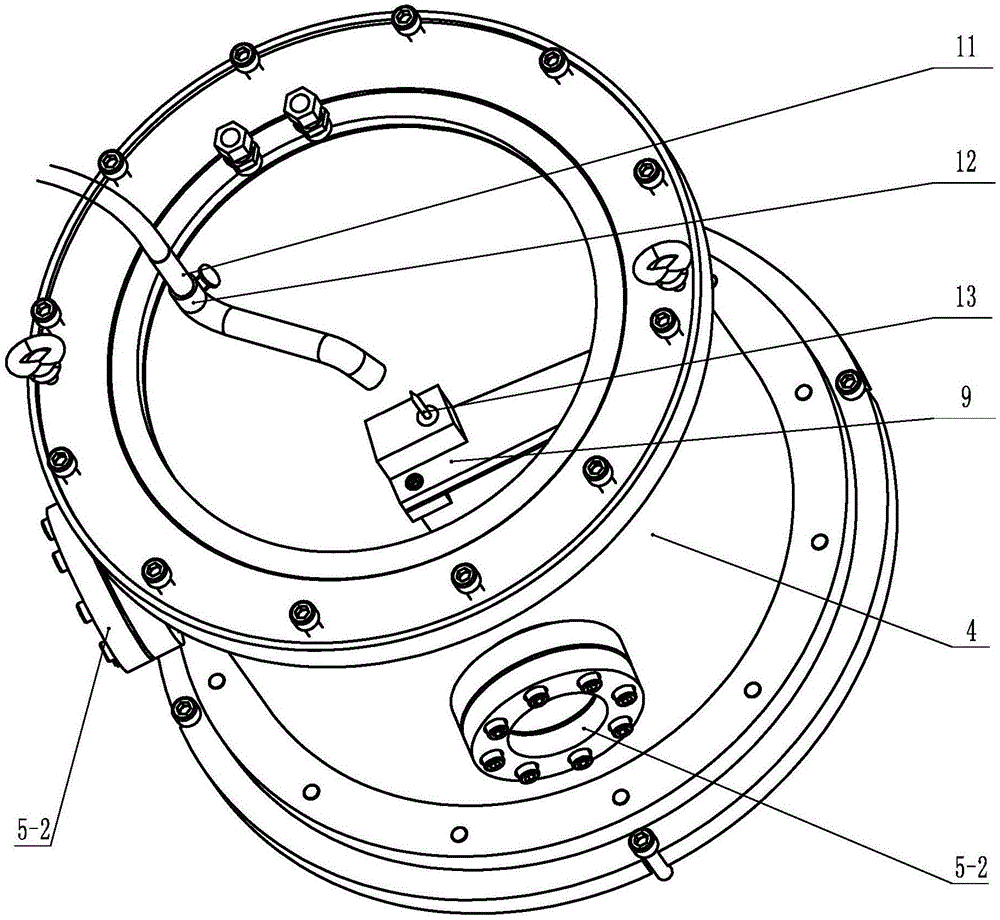

[0023] Specific implementation mode one: as Figure 1 to Figure 7 As shown, a compact vacuum reaction device for chemical vapor deposition of diamond films, which consists of a vacuum gauge 1, a needle valve 2, an upper cover 3, a housing 4, a base 6, a solenoid valve 7, and an infrared thermometer 8 , air guide tube 11, air guide valve 12, stage 9 and three observation windows 5; the three observation windows 5 are respectively observation window one 5-1 and two observation windows two 5-2;

[0024] The upper end and the lower end of the housing 4 are respectively detachably sealed with the upper cover 3 and the base 6, and the housing 4, the upper cover 3 and the base 6 are combined to form a reaction chamber, and the vacuum gauge 1 (by bolts) is fixed on the On the upper surface of the upper cover 3, the detection end of the vacuum gauge 1 is tightly penetrated into the through hole on the upper cover 3 and is arranged in the housing 4 (the vacuum gauge 1 is used to observe...

specific Embodiment approach 2

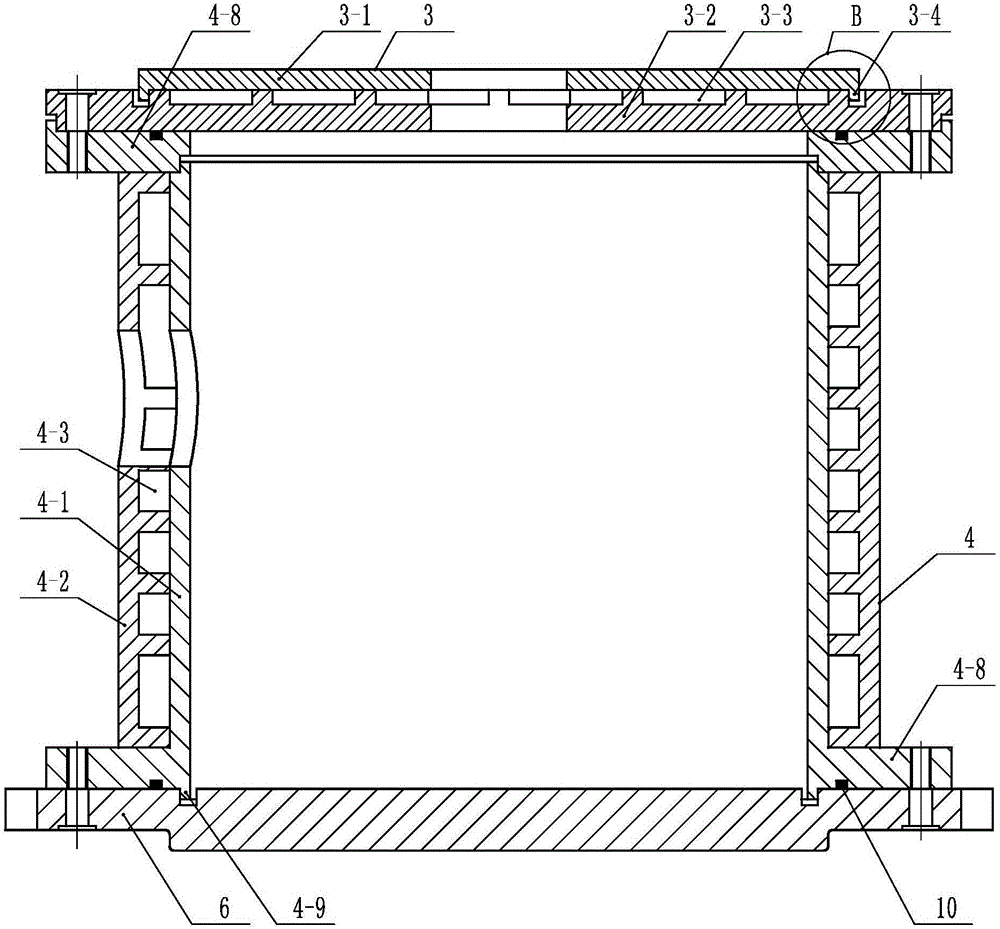

[0030] Specific implementation mode two: as figure 1 , image 3 , Figure 4 and Figure 7 As shown in the specific embodiment one, a compact vacuum reaction device for chemical vapor deposition of diamond films, the upper cover 3 is composed of a welding upper cover 3-1 and a cold water tank upper cover 3-2, the The welding loam cake 3-1 and the cold water tank loam cake 3-2 are disc-shaped, and the outer diameter of the welding loam cake 3-1 is less than the outer diameter of the cold water trough loam cake 3-2, and the cold water trough loam cake 3-2 is The upper surface of the 3-2 is processed with a plurality of said cold water ring grooves 3-3 concentric with the cold water groove upper cover 3-2, and a gap 1 is arranged on the inner side wall of each cold water ring groove 3-3, each The gaps of two adjacent cold water ring grooves 3-3 are set at a distance of 180°, and the upper surface of the cold water tank loam cake 3-2 is provided with a water tank partition wall ...

specific Embodiment approach 3

[0031] Specific implementation mode three: as figure 1 , image 3 and Figure 4 As shown, a compact vacuum reaction device for chemical vapor deposition of diamond films described in Embodiment 2, the upper surface of the cold water tank upper cover 3-2 is provided with an annular limiting groove-3 near the outer edge -7, the outer peripheral edge of the lower surface of the welded upper cover 3-1 is provided with a convex ring 3-4, and the convex ring 3-4 of the welded upper cover 3-1 is arranged on the top of the cold water tank cover 3-2 In the annular limit groove-3-7, and the inside surface of the convex ring-3-4 of the welding loam cake 3-1 matches with the annular limit groove-3-7 inner side surface of the cold water tank loam cake 3-2 (realize welding Loam cake 3-1 is concentric with cold water tank loam cake 3-2), the groove width of the annular limit groove-3-7 of cold water tank loam cake 3-2 is greater than the protruding ring-3-4 of welding loam cake 3-1 Thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com