Preparation, electrode and application of an electrode for electrochemical reduction of carbon dioxide

A carbon dioxide, electrochemical technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve problems such as high toxicity and limitation, and achieve the effect of improving lifespan, improving stability, and simple and controllable preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Toray060 carbon paper was treated in the air at 500°C, and then degreased and cleaned in ethanol or acetone as the substrate; in the presence of 0.04M Bi(NO 3 ) 3 With 25.4ml 36.5% HCl electrolyte solution at 30mA cm -2 Carry out metal deposition for 200s; wash and dry to finally obtain the electrode and oxidize it in the air at 20°C for 20min; place it in H 2 Reduction at 300°C for 60 minutes in a gas mixture with a volume ratio of 1:4 to Ar; after washing and drying, the electrode was finally obtained.

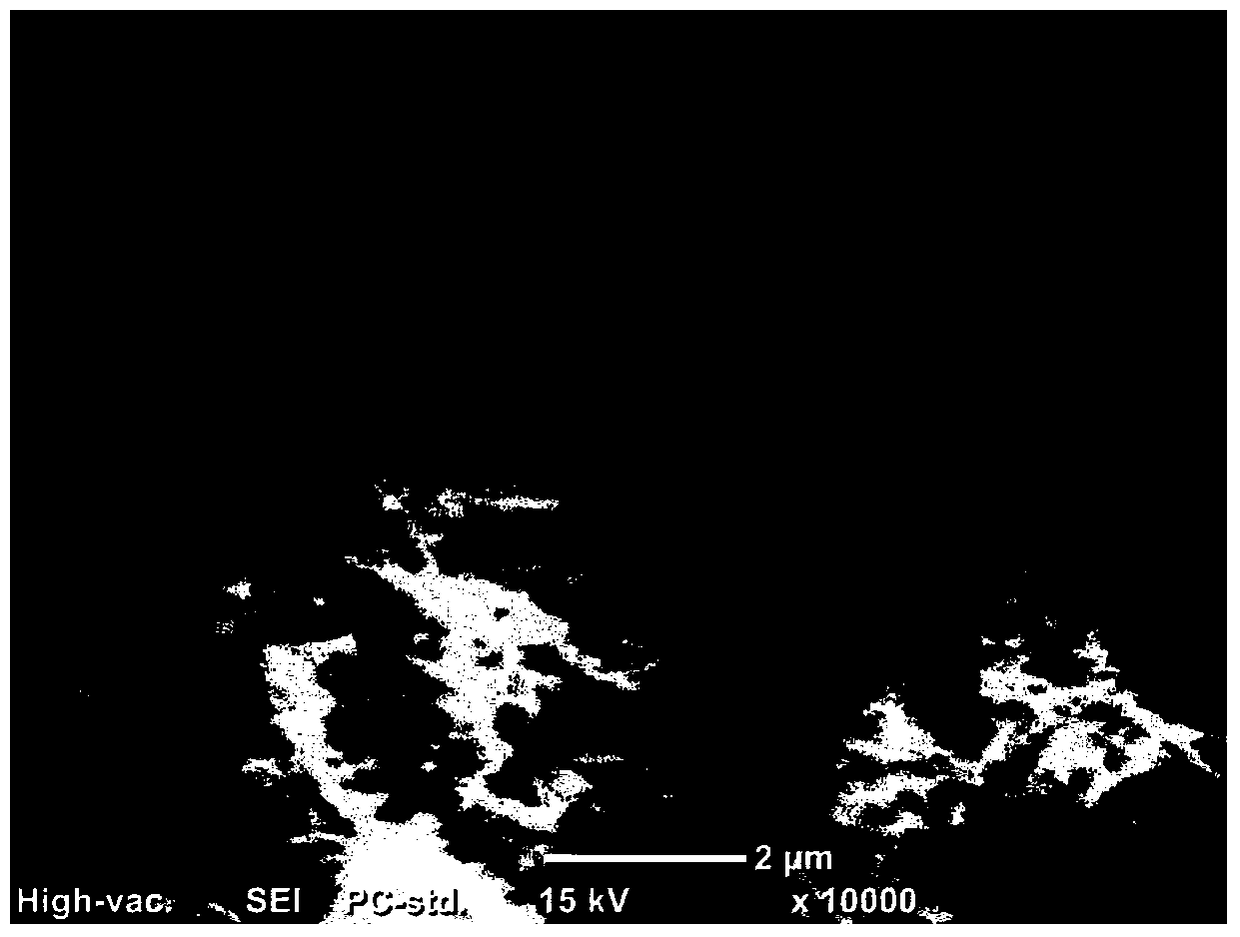

[0038] figure 1 It can be seen that the prepared electrode is a nanofibrous catalyst grown on carbon paper.

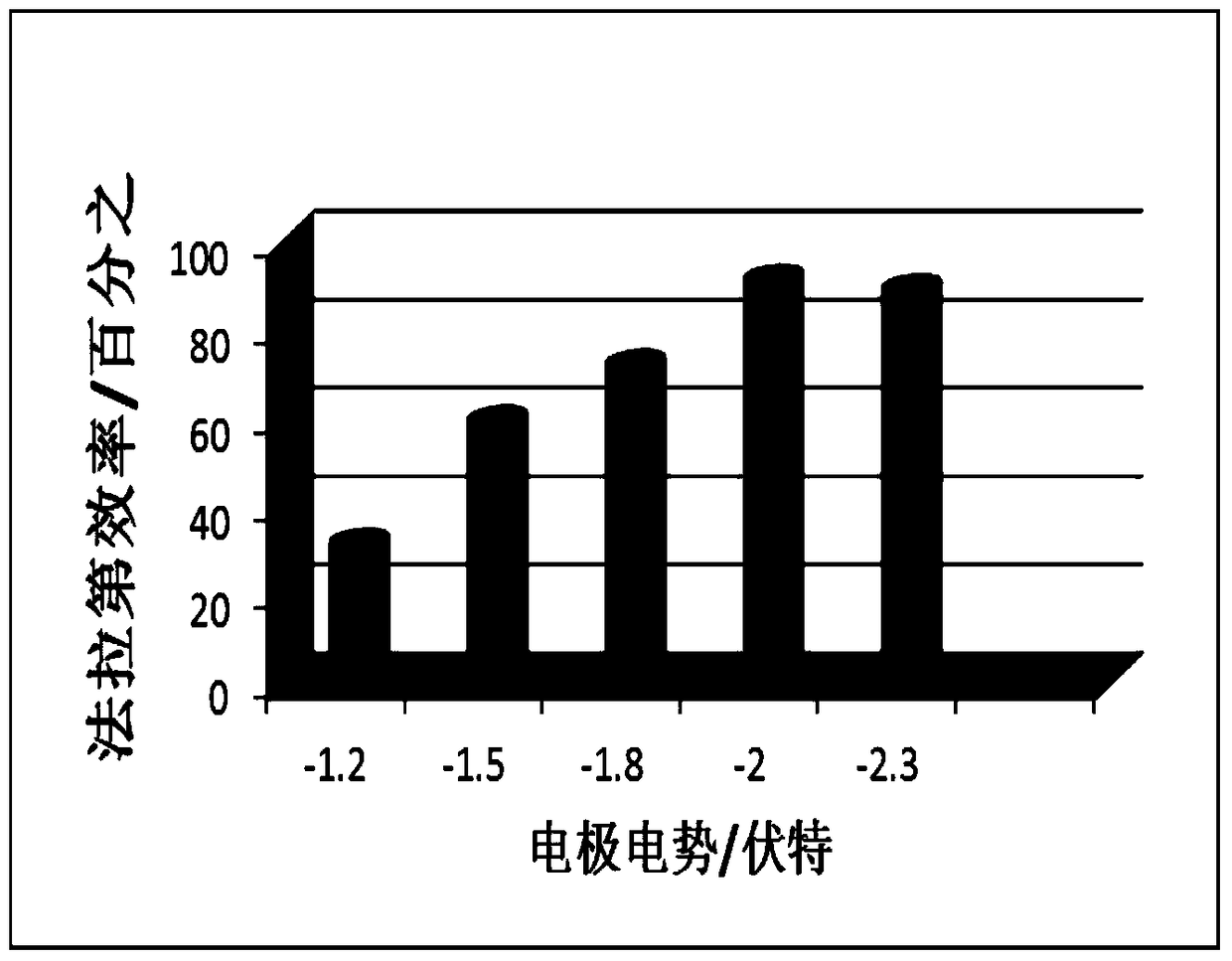

[0039] figure 2 The result in shows, embodiment 1 electrode has higher catalytic activity;

Embodiment 2

[0041] The carbon felt with a thickness of 200 μm was treated in the air at 550 ° C, and then degreased and cleaned in ethanol and acetone as the substrate; 3 ) 3 with 20.4ml of 36.5% HCl electrolyte solution at 120mAcm -2 Carry out metal deposition for 30s; wash and dry to finally obtain the electrode and oxidize it in air at 20°C for 60min; place it in H 2 Reduction at 300°C for 60 minutes in a gas mixture with a volume ratio of 1:4 to Ar; after washing and drying, the electrode was finally obtained.

Embodiment 3

[0043] Carbon paper with a thickness of 100 μm was treated in the air at 450 ° C, and then degreased in ethanol and acetone and cleaned as a substrate; 3 with 20.4ml of 36.5% HCl in electrolyte solution at 10mA cm -2 Carry out metal deposition for 30s; wash and dry to finally obtain the electrode and oxidize it in air at 400°C for 240min; place it in H 2 Reduction at 300°C for 60 min in a mixed gas with a volume ratio of 1:1 to Ar; after washing and drying, the electrode was finally obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com