Automatic adjusting system of hole sealing bath solution for aluminum profile

An automatic adjustment and sealing tank technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the waste of medicines, nickel ion salts are not easy to dissolve, and cannot ensure the continuous stability of the bath concentration and other problems to achieve the effect of reducing the phenomenon of dusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

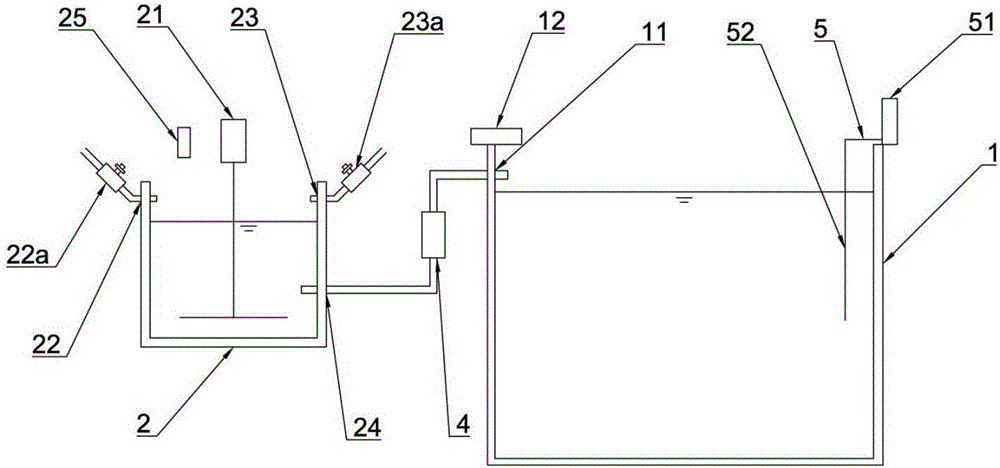

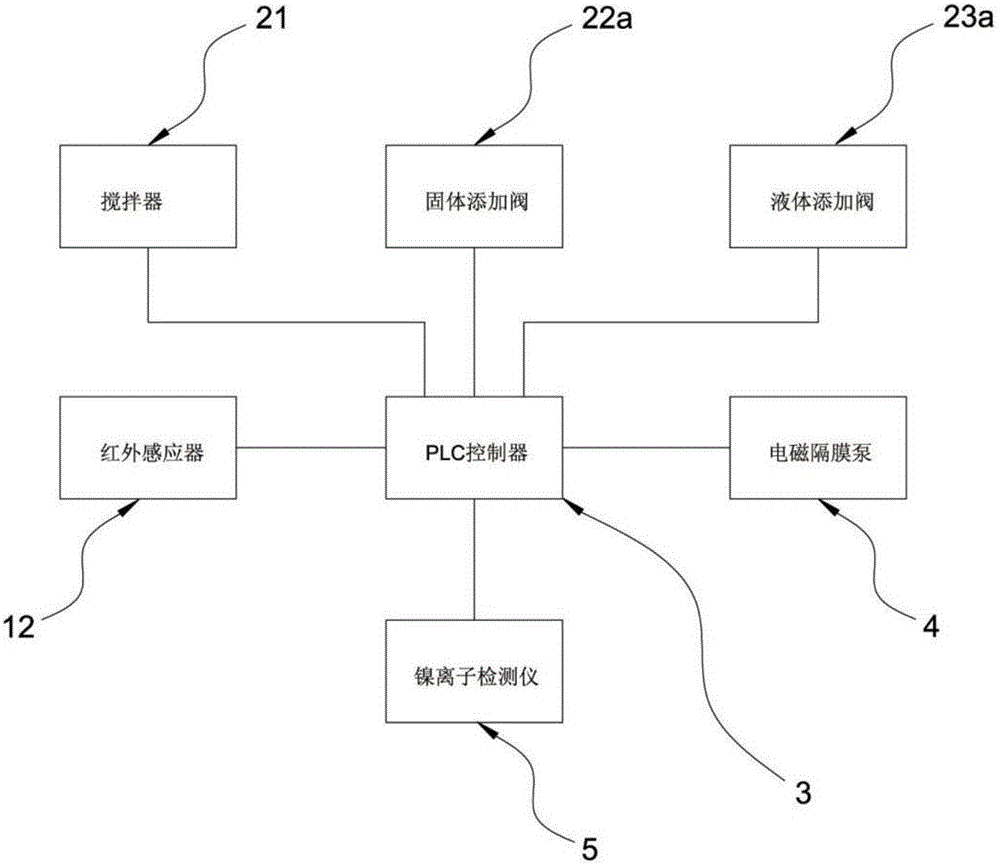

[0029] Such as figure 1 , 2 As shown, an automatic adjustment system for aluminum profile sealing tank liquid of the present invention includes a sealing tank body 1, and the system also includes a dosing barrel 2 with an agitator 21 inside and a PLC controller 3, and the dosing barrel 2 is A nickel salt addition port 22 containing a solid addition valve 22a, a deionized water addition port 23 containing a liquid addition valve 23a, a drug outlet 24, and a liquid level gauge 25 are provided. The liquid level gauge 25 is located above the dosing barrel 2 and faces the dosing Liquid surface of barrel 2, medicine inlet 11 and infrared sensor 12 are provided on sealing tank body 1, medicine outlet 24 is connected with medicine inlet 11 through electromagnetic diaphragm pump 4, infrared sensor 12 is arranged on the upper end of sealing tank body 1 and faces Above the liquid level, the PLC controller 3 is respectively connected to the solid addition valve 22a, the liquid addition v...

Embodiment 2

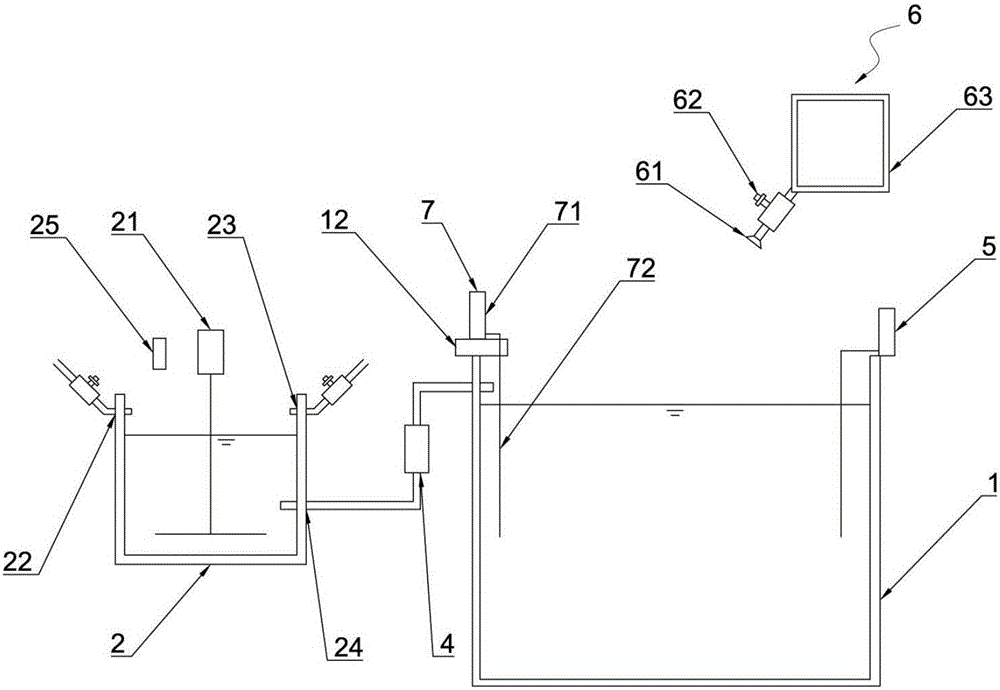

[0035] Such as image 3 , 4 As shown, on the basis of Embodiment 1, the present invention also includes a spray device 6 arranged above the sealing tank body. The spray device 6 includes a spray head 61, a spray valve 62 and a liquid storage tank 63. The spray head 61 is connected with liquid storage tank 63 through spray valve 62 , and spray valve 62 is connected with PLC controller 3 .

[0036] A pH value detector 7 is also arranged in the sealing tank body 1, and the pH value detector 7 is connected with the PLC controller 3. The pH value detector 7 includes a pH value display terminal 71 and a pH value detection terminal 72, and the pH value detection terminal 72 It is arranged below the liquid surface in the sealed hole tank body 1 , and the pH value display terminal 71 is arranged on the outer wall of the hole sealed hole body 1 .

[0037] On the basis of the work of embodiment 1, the working mode of the present embodiment also includes:

[0038] The PH value will dec...

Embodiment 3

[0041] Such as Figure 5 , 6 Shown, the present invention also comprises filter device 8 on the basis of embodiment 2, and filter device 8 comprises filter tube 81, filter valve 82 and suction pump 83, and filter tube 81 is provided with a plurality of filter holes 81a, and filter tube 81 It is installed at the bottom of the sealing tank 1 and extends out of the sealing tank 1 and is connected to the suction pump 83 through the filter valve 82 , and both the filter valve 82 and the suction pump 83 are connected to the PLC controller 3 .

[0042] On the basis of the work of embodiment 2, the working mode of the present embodiment also includes:

[0043] Colloidal sediment will be produced during the sealing and coloring process. The PLC controller regularly opens the filter valve and suction pump to suction and filter the colloidal sediment to ensure that there are no precipitated impurities in the sealing tank, which can effectively reduce the coloring material sealing. Ash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com