5,5-diphenyl-2,4-imidazolidinedione sodium salt compounding butanetetracarboxylic acid fabric anti-crease finish agent

A technology of imidazolidinedione sodium salt and butane tetracarboxylic acid, which is applied in the fields of fiber treatment, plant fiber, textiles and papermaking, etc., can solve the problems of high processing cost of finishing fabrics, high cost of finishing process, high phosphorus compound, etc., and achieves Increase efficiency and completeness of esterification crosslinking, reduce processing cost, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

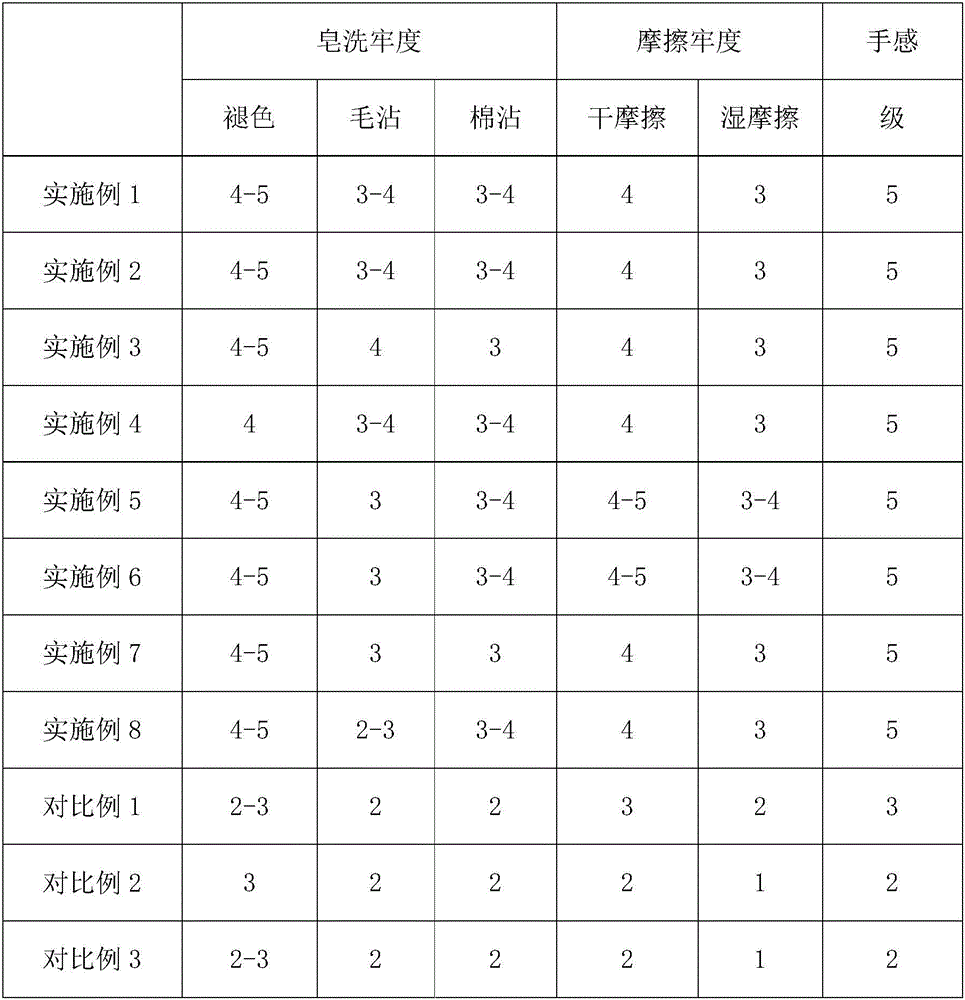

Examples

Embodiment 1

[0030] A 5,5-diphenyl-2,4-imidazolidinedione sodium salt complex butane tetracarboxylic acid fabric anti-wrinkle finishing agent, which is composed of 5,5-diphenyl-2,4-imidazolidinedione It is prepared by mixing sodium salt with butane tetracarboxylic acid, and the weight ratio of the two is 1:120.

[0031] Its finishing process includes the following processes:

[0032] Mix 5,5-diphenyl-2,4-imidazolidinedione sodium salt and butane tetracarboxylic acid according to the weight percentage ratio, then add water to form a finishing bath (the concentration of the mixed finishing agent is 0.1% ), and soak the cotton fabric in the finishing bath (bath ratio is 30:1);

[0033] Then, it is rolled on the rolling car by two dipping and two rolling methods, the time is 10min, and the liquid rolling rate is 100%; then pre-baking treatment is carried out, the treatment temperature is 50°C, and the pre-baking time is 100s; then baking treatment , the treatment temperature is 110°C, and th...

Embodiment 2

[0036] A 5,5-diphenyl-2,4-imidazolidinedione sodium salt complex butane tetracarboxylic acid fabric anti-wrinkle finishing agent, which is composed of 5,5-diphenyl-2,4-imidazolidinedione It is prepared by mixing sodium salt with butane tetracarboxylic acid, and the weight ratio of the two is 1:200.

[0037] Its finishing process includes the following processes:

[0038] Mix 5,5-diphenyl-2,4-imidazolidinedione sodium salt and butane tetracarboxylic acid according to the weight percentage ratio, then add water to form a finishing bath (the mass percent concentration of the mixed finishing agent is 1.0% ), and soak the cotton fabric in the finishing bath (bath ratio is 40:1);

[0039] Then, it is rolled on the rolling car by two dipping and two rolling methods, the time is 10min, and the liquid rolling rate is 100%; then pre-baking treatment is carried out, the treatment temperature is 70°C, and the pre-baking time is 120s; then baking treatment , the treatment temperature is ...

Embodiment 3

[0042] A 5,5-diphenyl-2,4-imidazolidinedione sodium salt compound butane tetracarboxylic acid fabric anti-wrinkle finishing agent, 5,5-diphenyl-2,4-imidazolidinedione sodium The weight ratio of salt to butane tetracarboxylic acid added is 1:150.

[0043] Its finishing process includes the following processes:

[0044] Mix 5,5-diphenyl-2,4-imidazolidinedione sodium salt and butane tetracarboxylic acid according to the weight percentage ratio, then add water to form a finishing bath (the concentration of the mixed finishing agent is 0.1% ), and soak the cotton fabric in the finishing bath (bath ratio is 40:1);

[0045] Then, it is rolled on the rolling car by two dipping and two rolling methods, the time is 10min, and the liquid rolling rate is 100%; then pre-baking treatment is carried out, the treatment temperature is 50°C, and the pre-baking time is 120s; then baking treatment , the treatment temperature is 120°C, and the treatment time is 100s;

[0046] Finally, soaping, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com