Composite wall board and manufacturing method and application thereof

A composite wallboard and technology for its production method, which is applied in the field of building materials, can solve problems such as thermal insulation and sound insulation, which are convenient and unsatisfactory, and achieve the effect of simple and easy preparation method and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

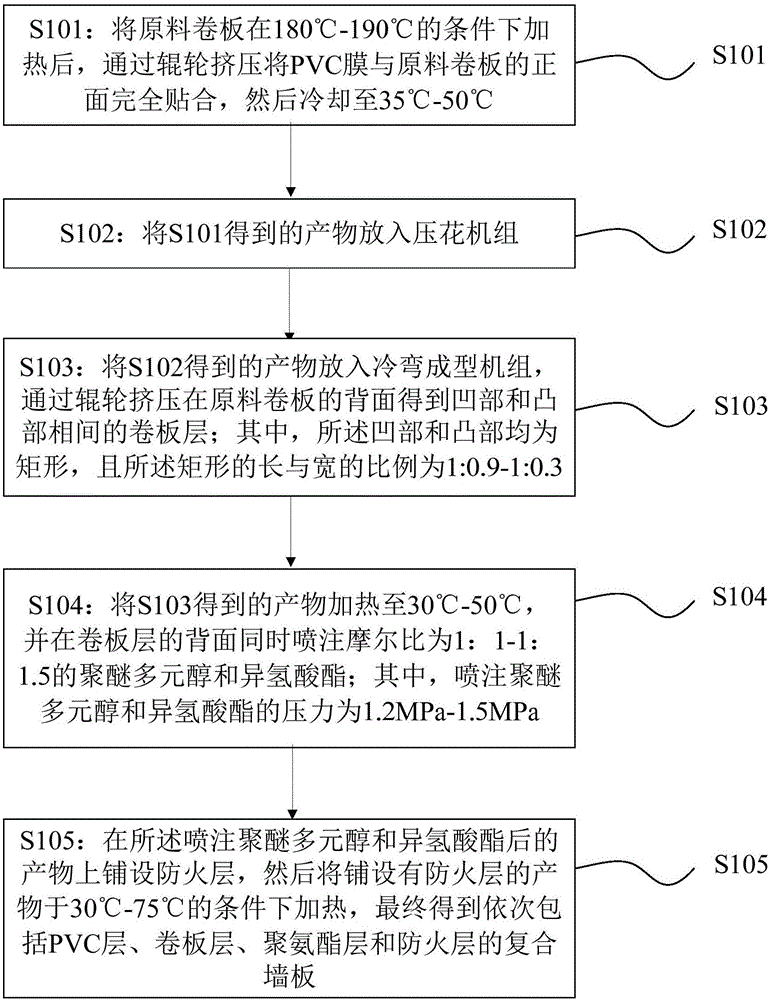

Method used

Image

Examples

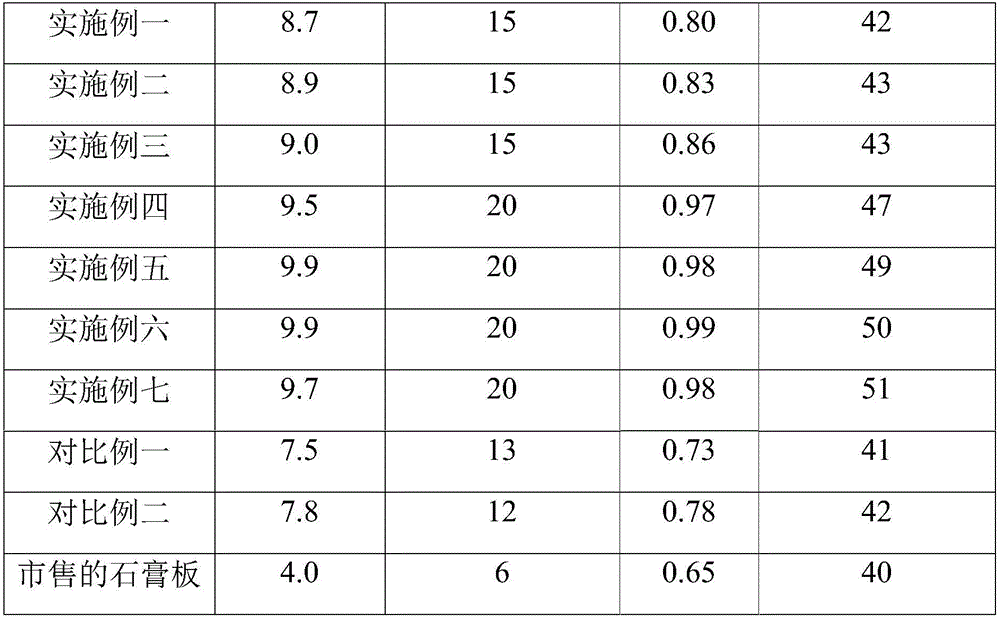

Embodiment 1

[0026] The galvanized coil with a thickness of 1mm enters the embossing unit, and the galvanized coil processed by the embossing unit enters the cold bending forming unit, heats the galvanized coil to 30°C, and coats the surface of the galvanized coil with The pressure of 1.3MPa was simultaneously sprayed with PTMEG-1000 polytetrahydrofuran ether glycol and 4,4'-diphenylmethane diisocyanate with a molar ratio of 1:1.5, and allowed to stand for 70 minutes to obtain a polyurethane layer with a thickness of 48.7mm; After standing for 70 minutes, the product will continue to move forward under the thrust of cold bending, and then lay a glass fiber cloth with a thickness of 0.3mm on the product injected with PTMEG-1000 and 4,4'-diphenylmethane diisocyanate , and then the product covered with glass fiber cloth is sent to a double-layer hot-press conveyor, and shaped at 43°C; finally, a composite wallboard with a thickness of 50mm is obtained, and the composite wallboard includes a la...

Embodiment 2

[0028] The galvanized coil with a thickness of 1mm enters the embossing unit, and the galvanized coil processed by the embossing unit enters the cold bending forming unit, and the coil layer with concave and convex parts is obtained through roller extrusion; among them, the concave part Both the convex part and the convex part are rectangular, and the ratio of the length to the width of the rectangle is 1:0.6. Heat the coil layer to 30°C, and simultaneously spray polytetrahydrofuran ether glycol and 4,4'-diphenyl with a molar ratio of 1:1.5 in the concave part of the coil layer at a pressure of 1.3MPa Methane diisocyanate, standing for 70 minutes, to obtain a polyurethane layer with a thickness of 48.7mm; the product after standing for 70 minutes will continue to move forward under the thrust of cold bending, and then sprayed with PTMEG-1000 and 4,4'-di Lay a glass fiber cloth with a thickness of 0.3mm on the product of phenylmethane diisocyanate, and then send the product cov...

Embodiment 3

[0030] The aluminum coil with a thickness of 0.5mm enters the embossing unit, and the aluminum coil processed by the embossing unit enters the cold bending forming unit, and the coil layer with concave and convex parts is obtained through roller extrusion; among them, the concave and convex The convex parts are all rectangular, and the ratio of the length to the width of the rectangle is 1:0.3. Heat the coil layer to 45°C, and simultaneously spray polytetrahydrofuran ether glycol and 4,4'-diphenyl with a molar ratio of 1:1.3 in the concave part of the coil layer at a pressure of 1.5MPa Methane diisocyanate, standing for 90 minutes, to obtain a polyurethane layer with a thickness of 49.3mm; the product after standing for 90 minutes will continue to move forward under the thrust of cold bending, and then sprayed with PTMEG-1000 and 4,4'-di Lay a glass fiber cloth with a thickness of 0.2mm on the product of phenylmethane diisocyanate, and shape it at 35°C; finally obtain a compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com