Amphetamine tablet homogenization method

A homogenization technology of amphetamines, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of reducing the accuracy and repeatability of drug detection, poor distribution uniformity of active ingredients, and poor production conditions, etc., to achieve crushing Good effect, good cleaning effect, reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0047] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

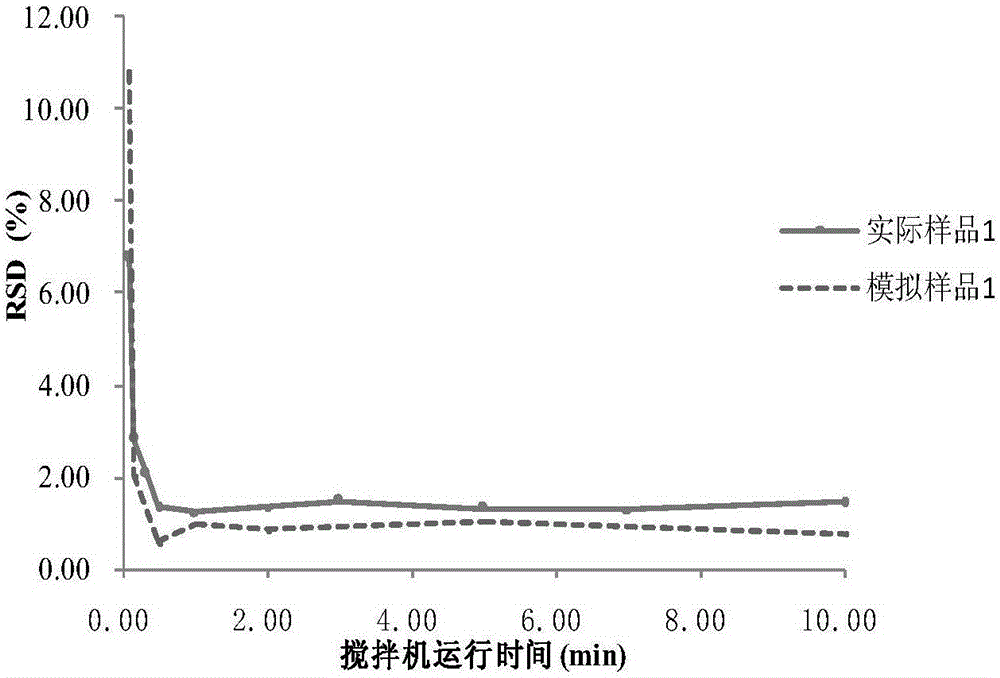

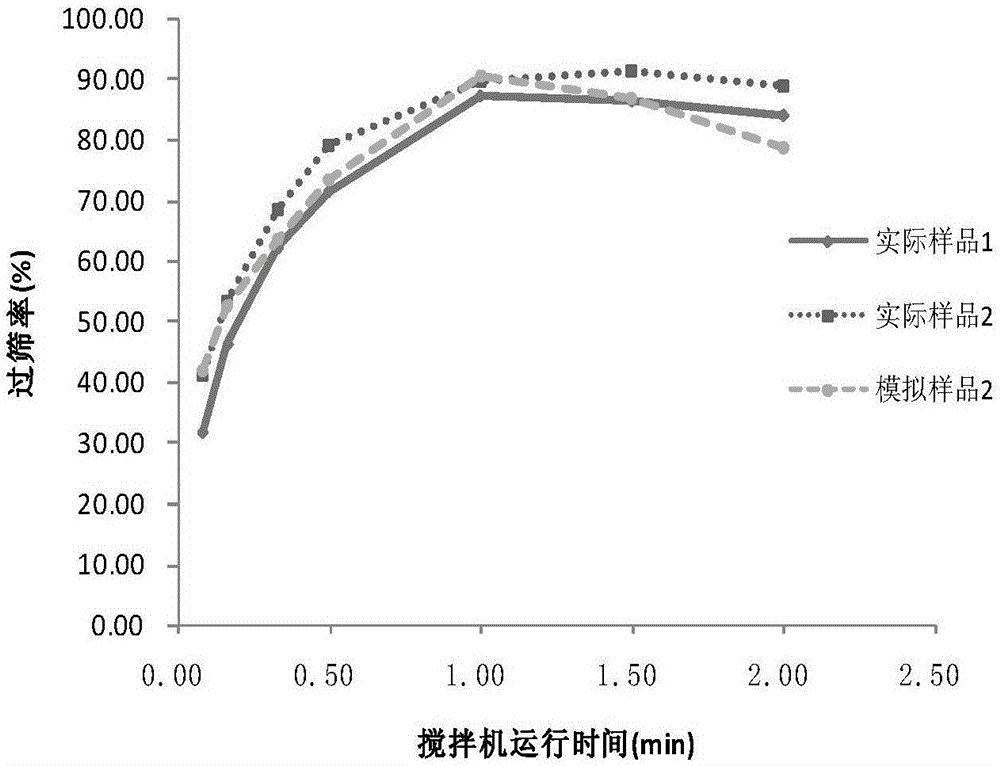

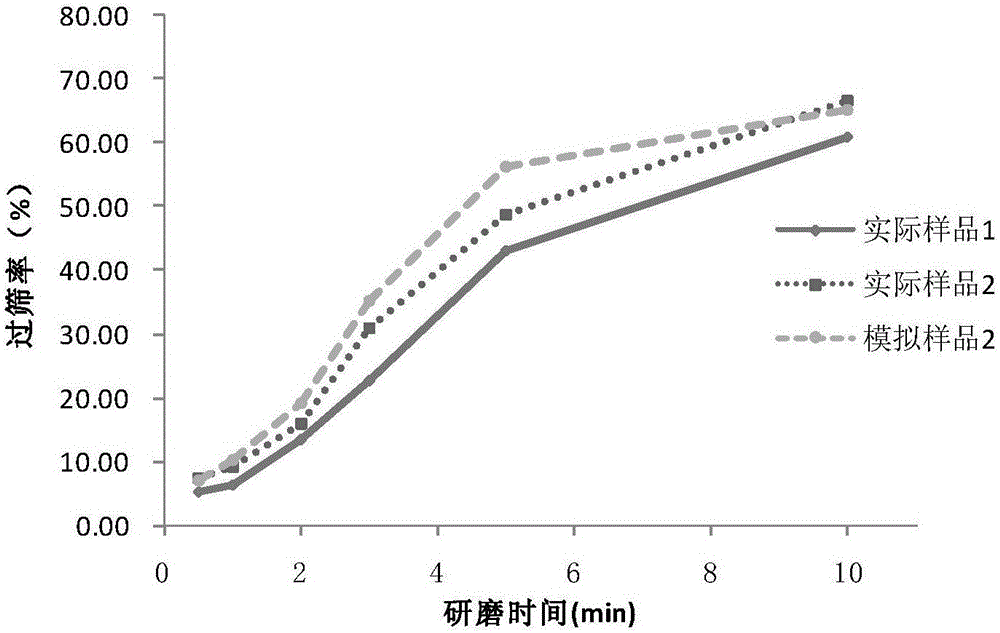

[0048] The following examples take the methamphetamine tablet (the most common amphetamine tablet) as the experimental sample, and use the household mixer as the homogenization equipment of the tablet sample (simulated sample and actual sample), investigate the effect and The feasibility of the cleaning method, meanwhile, was compared with the traditional manual grinding method in a mortar and pestle. The relative standard deviation of the content of the target substance in the sample homogenized by a household mixer and the particle size of the pulverized sample are used as evaluation criteria to discuss the required mixing time; the evaluation standard is whether the target substance remains in the homogenization equipment , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com