Fiber-based atomic force microscope probe and atomic force microscope system

An atomic force microscope and optical fiber technology, applied in scanning probe microscopy, scanning probe technology, instruments, etc., can solve the problems of complex measurement system, material temperature drift error stress, high cost, etc., and achieve high measurement accuracy and sensitivity, The effect of simplifying the difficulty of system use and solving stress problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

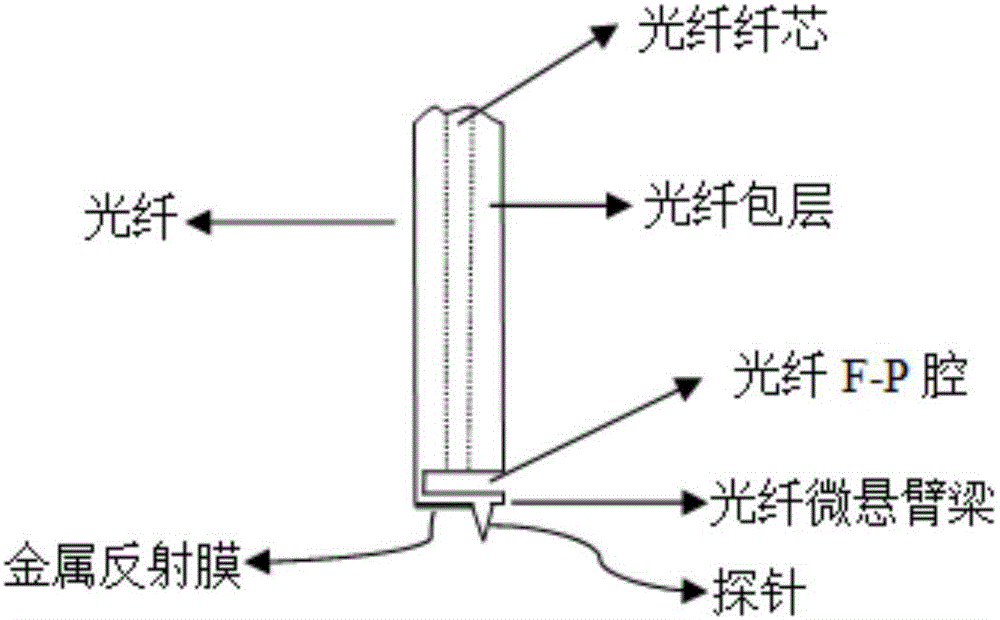

[0052] Example 1: A fiber-based atomic force microscope probe

[0053] Such as image 3 and Figure 7 As shown, the optical fiber-based atomic force microscope probe mainly includes a probe 5, a micro-cantilever beam 4, an optical fiber F-P cavity 5, and a light-transmitting optical fiber. The technology (dry etching, anisotropic wet etching) is integrated and processed on the tip of a 125μm diameter optical fiber. The probe 5, the micro-cantilever beam 4 and the optical fiber F-P cavity 3 are an integral structure, which can be integrally processed and formed without connecting parts. In addition, the probe 5 can also be prepared separately instead of an integrated structure, and then bonded to one end of the micro-cantilever beam through other processing techniques, which can ensure the diversity of probe structure and material selection and expand the scope of use of the system; One side of the probe is coated with a highly reflective metal film, a dielectric reflective ...

Embodiment 2

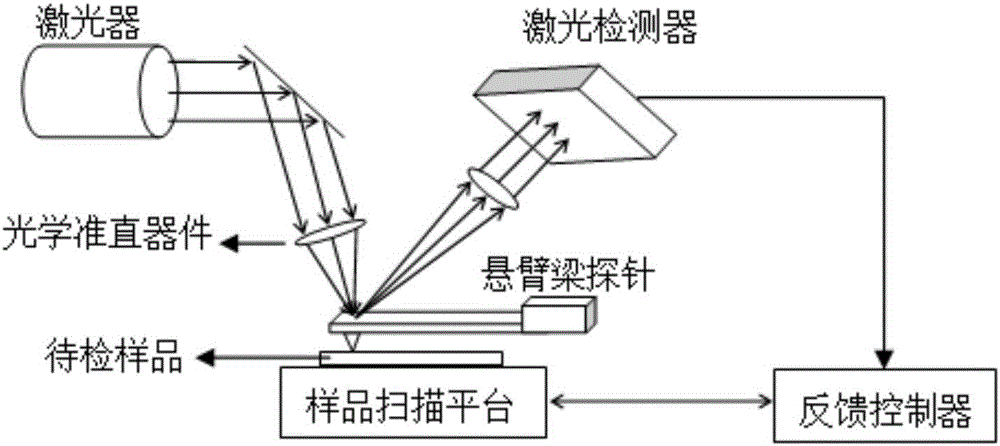

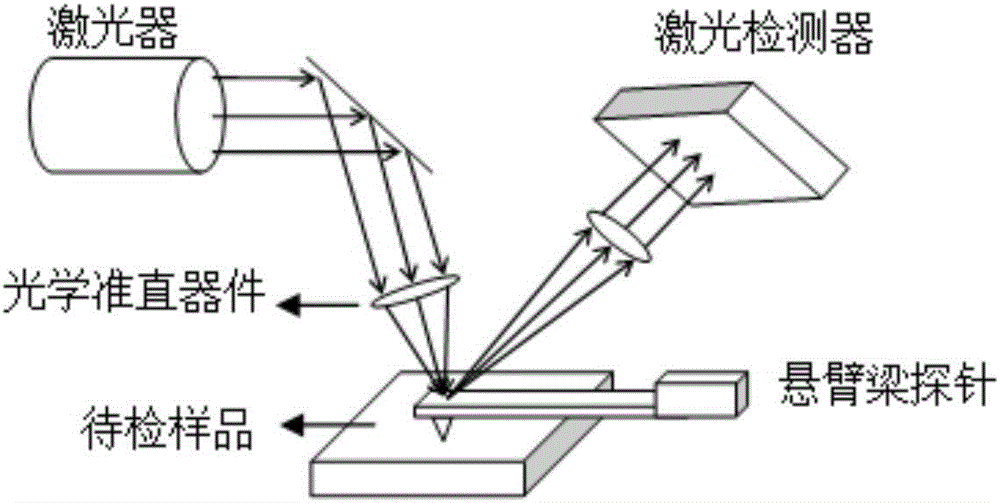

[0061] Example 2: An atomic force microscope system based on a fiber optic atomic force microscope probe

[0062] Such as Figure 6 As shown, an atomic force microscope system based on a fiber-optic atomic force microscope probe includes the above-mentioned fiber-based atomic force microscope probe, transmission fiber, coupler, laser light source, light intensity detection device, feedback controller and displacement scanning platform. When the probe is very close to the sample surface, a weak van der force is generated between the atoms at the tip of the probe and the atoms on the sample surface. When the light-transmitting fiber is transmitted to the top of the fiber, the interface light reflection will occur at the position of the fiber F-P cavity, and the reflected light will return to the optical signal detection device through the original path of the fiber; and the change of the length of the F-P cavity caused by the micro-cantilever microvariation will cause the reflec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Cavity length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com