Optical film, lighting module including the same and display including lighting module

A light-emitting device and optical film technology, applied in optics, optical components, nonlinear optics, etc., can solve problems such as inability to fully express color, color deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

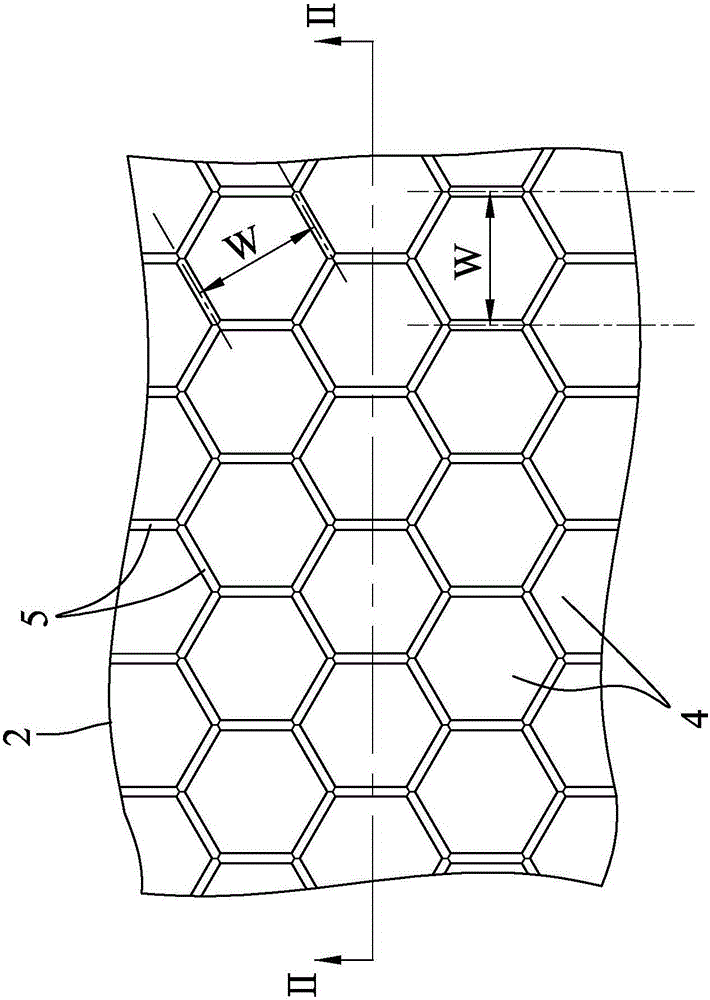

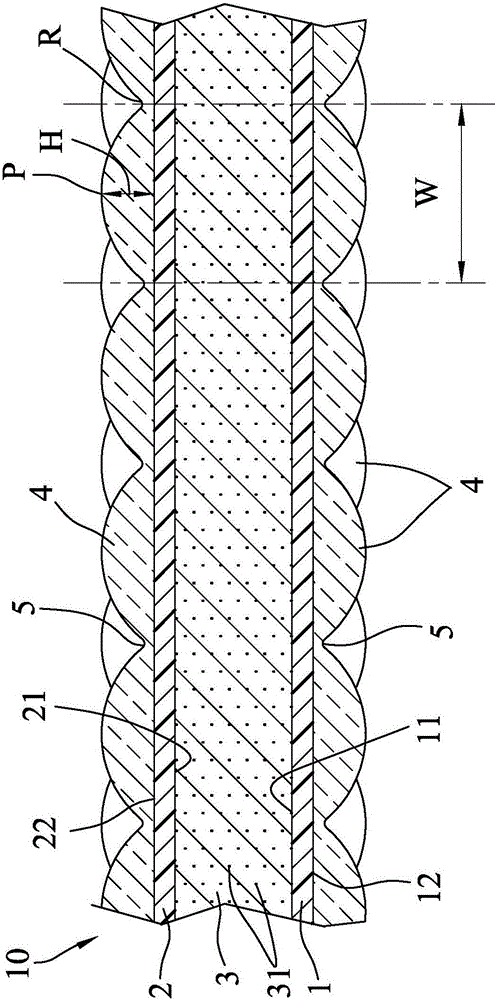

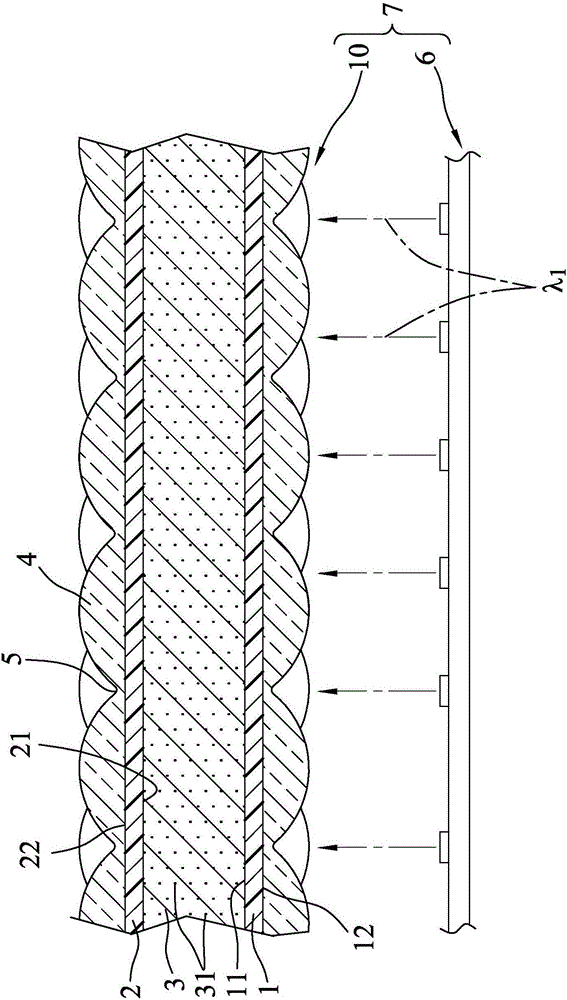

[0035] refer to figure 1 and figure 2 , a first embodiment of the optical film 10 of the present invention comprises a first substrate 1, a second substrate 2, a diffusion layer 3 between the first substrate 1 and the second substrate 2, And a plurality of microstructures 4 formed on the first substrate 1 and the second substrate 2 .

[0036] The first substrate 1 includes a first surface 11 and a light incident surface 12 opposite to the first surface 11 . The second substrate 2 is spaced apart from the first substrate 1 and includes a second surface 21 facing the first surface 11 and a light emitting surface 22 opposite to the second surface 21 . Wherein, the first base material 1 and the second base material 2 are made of a flexible transparent material. The flexible transparent material suitable for this embodiment can be polyethylene terephthalate (polyethylene terephthalate, PET), polyethylene naphthalate (polyethylenenaphthalate, PEN), or polycarbonate (polycarbonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com