Semi-analysis modeling method of contact area between ball-end milling cutter and guide vane

A technology of guide vanes and ball-end milling cutters, applied in instruments, digital control, control/regulation systems, etc., can solve problems such as the influence of the accuracy of the boundary equation in the contact area, and achieve the effect of improving computational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0059] The specific implementation manner is mainly divided into the following steps, and each step is described in detail below.

[0060] 1. Get the 3D model of the guide vane, plan the tool path, and set the CNC machining parameters. The specific content is as follows:

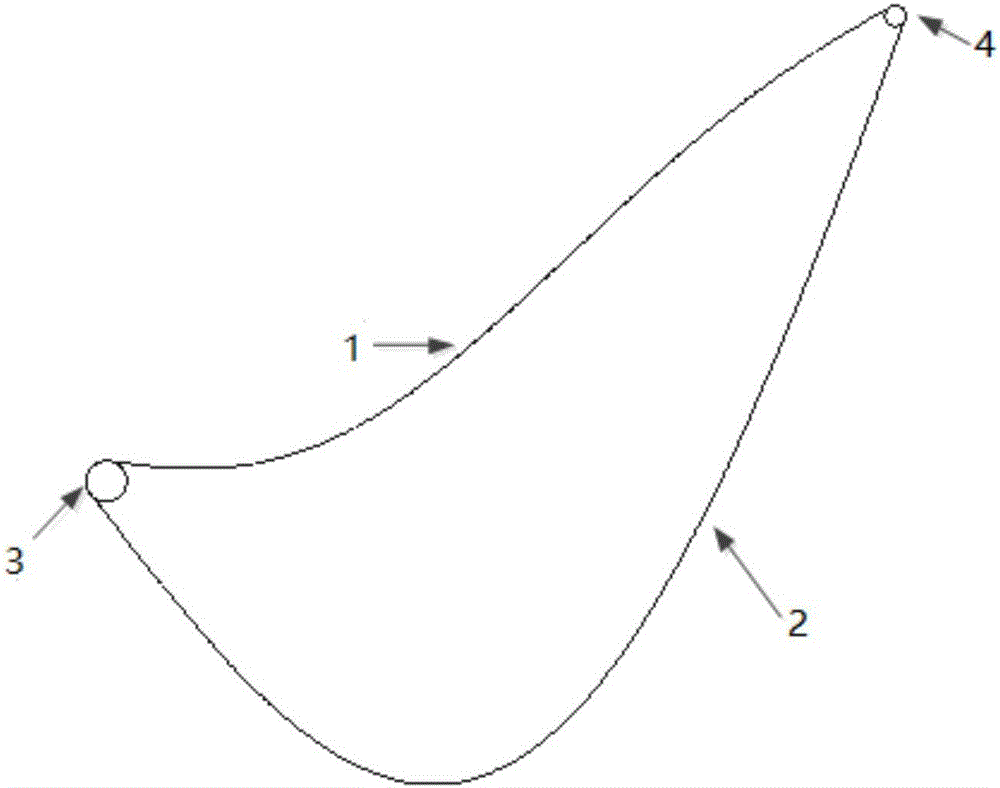

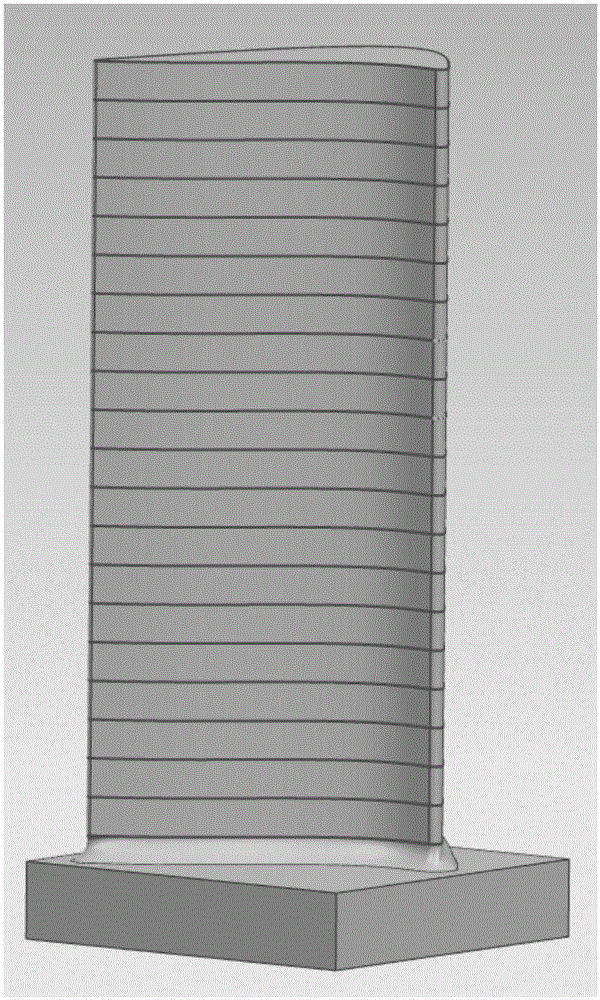

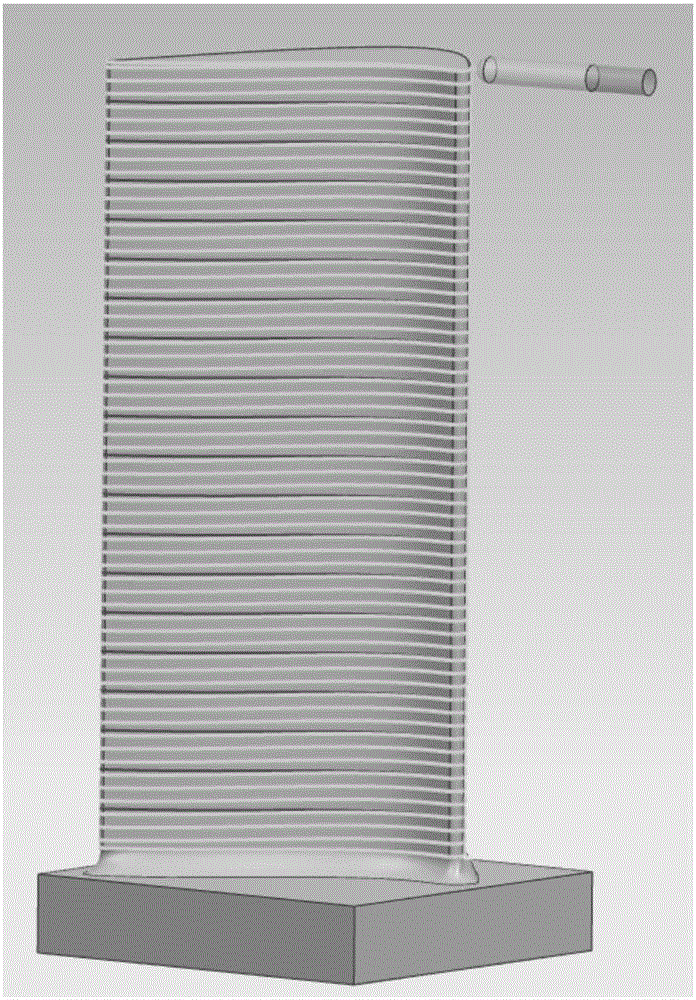

[0061] The cascade theory is used to design the three-dimensional guide vane. The expressions of the suction surface 1 and the pressure surface 2 of the guide vane are high-order polynomials. The leading edge 3 and the trailing edge 4 are circular arcs. The section of the guide vane adopts cascade parametric modeling. The sections of the guide vanes are stacked in a straight line to form the airfoil. The cross section of the guide vane is figure 1 As shown, the guide vane as figure 2 shown.

[0062] Import the guide vane into the commercial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com