A contact element and its preparation method

A contact element and condition technology, applied in the direction of electrical components, elastic connectors, connections, etc., can solve the problems of not meeting the requirements of large current and shock vibration, unstable quality of contact elements, high production cost, etc., to ensure high current, Good machinability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

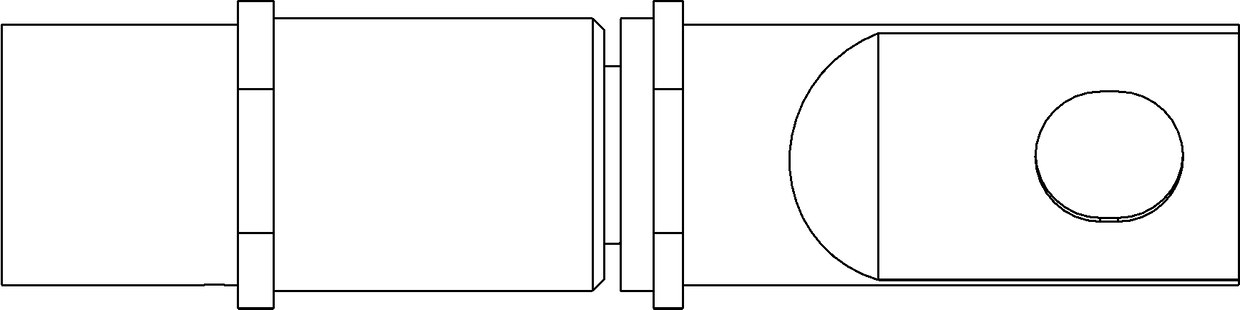

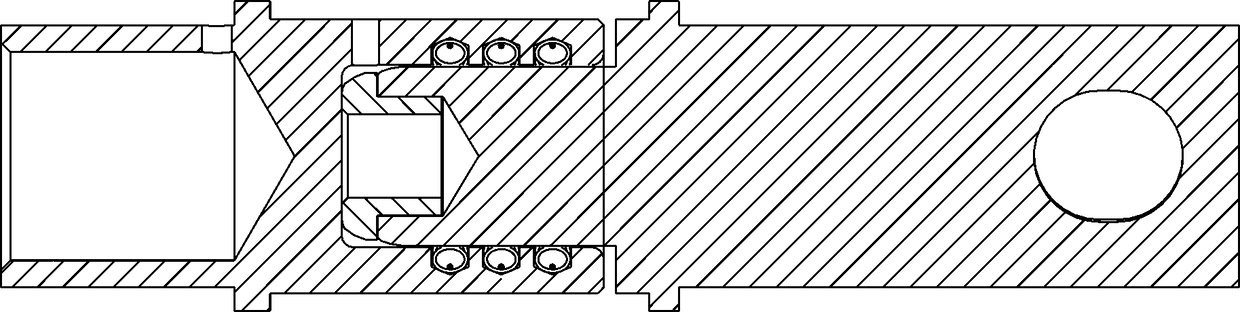

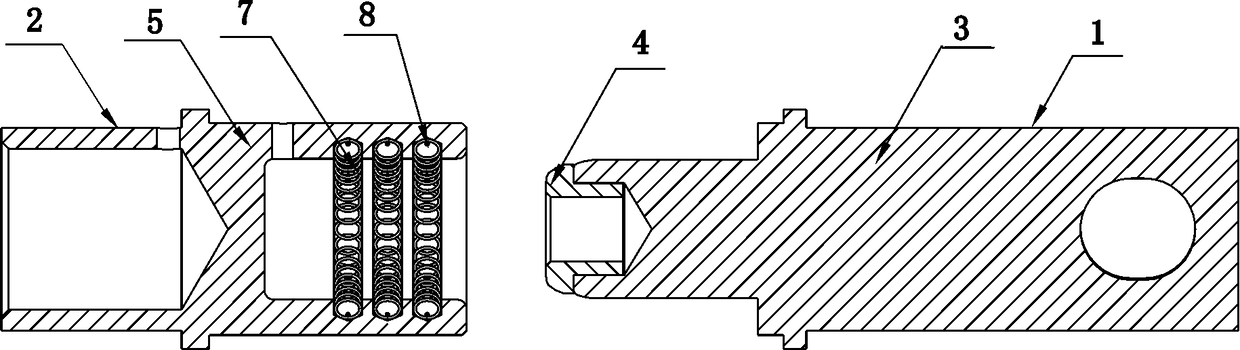

[0053] refer to Figure 1-8 , this embodiment provides a contact element, including a pin 1 and a socket assembly 2 matching the pin 1 .

[0054] The pin 1 includes a pin body 3 and an insulating cap 4. The insulating cap 4 is arranged on the front end of the pin body 3 and has an interference fit with the pin body 3. The function of the insulating cap 4 is to prevent conduction. When the pin 1 is installed on the plug 19, if pin 1 conducts electricity, the insulating cap 4 in pin 1 can play an insulating role to avoid electric shock to the human body; the second function is to prevent arcing. When plugging and unplugging with power, the insulating cap 4 in pin 1 is the first Contact with the socket assembly 2 can prevent the generation of electric arc.

[0055] The socket assembly 2 includes a socket body 5 and a ring spring 6; the groove of the socket body 5 is a 135° V-shaped groove, the groove width is greater than the height of the ring spring 6, the inner diameter of th...

experiment example

[0071] Taking the Φ15 ring spring as an example, the spring wire is 0.3mm, the inner diameter of the ring spring is 15mm, and the height is 3mm. It is assembled into a contact element, and then the electrical performance test is performed on the contact element:

[0072] Contact resistance: test conditions USCAR-2, Section 5.3.1.4, test requirements <1.5mΩ, actual test value is 0.22 mΩ, which meets the requirements.

[0073] Static heating: the test requires a connection of 135mm 2 Cable, current 400A, temperature rise < 42°C, actual test value 30°C, meet the requirements.

[0074] Plugging life: The test requires 10,000 cycles of plugging and unplugging, and the temperature rise is tested every 2,000 times. The temperature rise is <42°C, and the separation force is recorded. The actual separation value begins to be about 23N. With the increase of the number of plugging and unplugging, the separation force gradually After 10,000 times of plugging and unplugging, the separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com