A kind of preparation method of fiber reinforced ceramic matrix composite material with low thermal expansion coefficient

A technology with low thermal expansion coefficient and thermal expansion coefficient, which is applied in metal material coating process, coating, gaseous chemical plating, etc., can solve problems such as system failure and image deformation, and achieve short cycle time and high production efficiency.

The effect of low cost and simple preparation process

Active Publication Date: 2016-05-11

SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Deviation, causing the system not to work properly and the image to be distorted

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

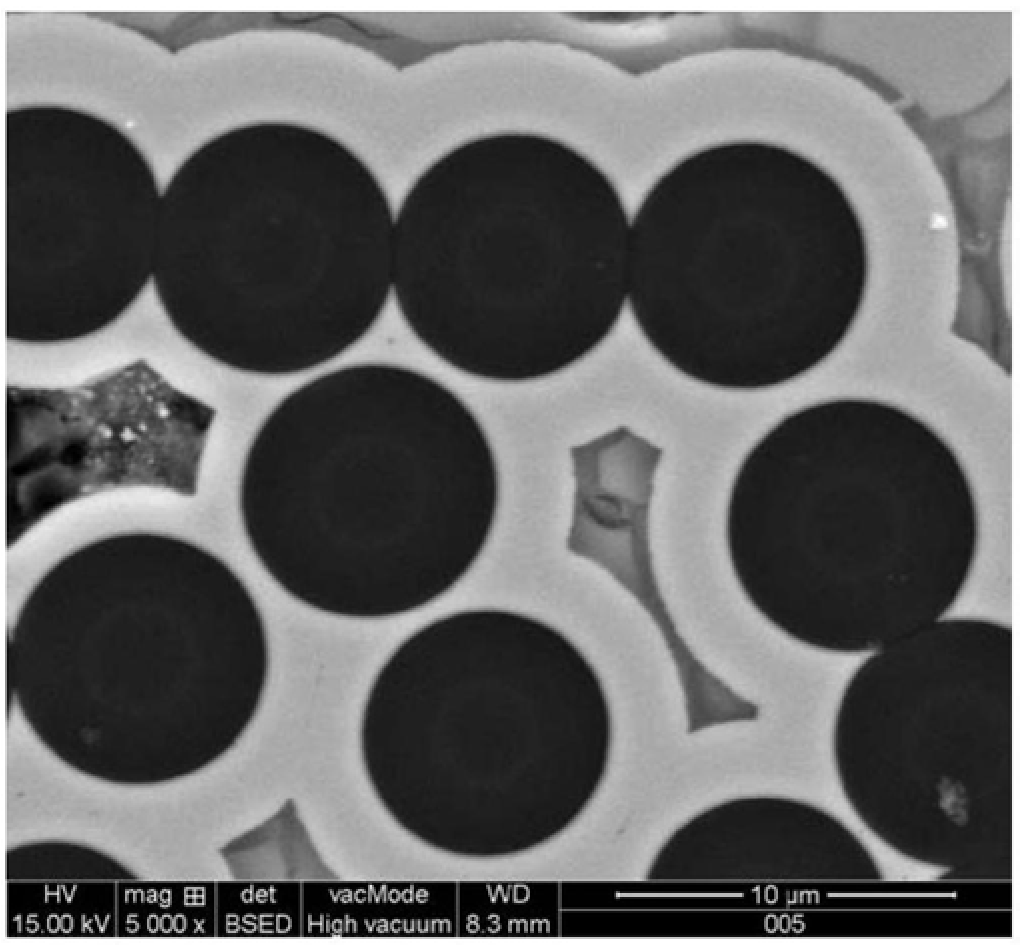

[0028] According to the same process as Example 1 to prepare the composite material, the difference is that the deposition time is extended to 15h. complex

Embodiment 3

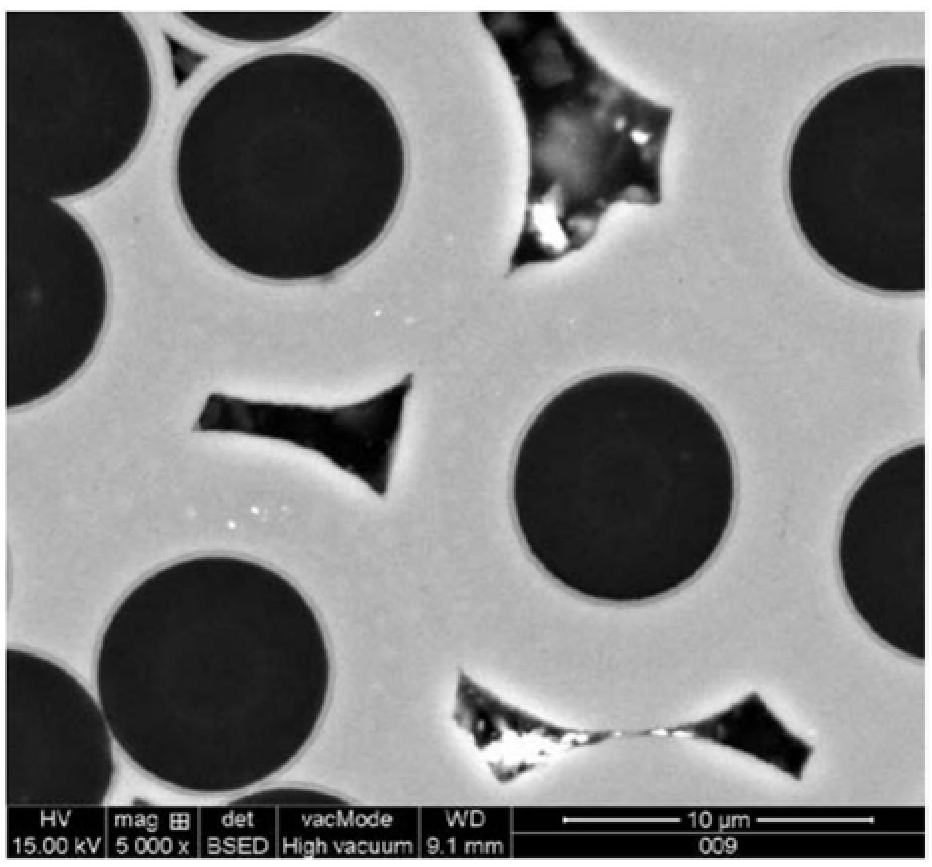

[0030] According to the same process as Example 1 to prepare the composite material, the difference is that the deposition time is extended to 20h. complex

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

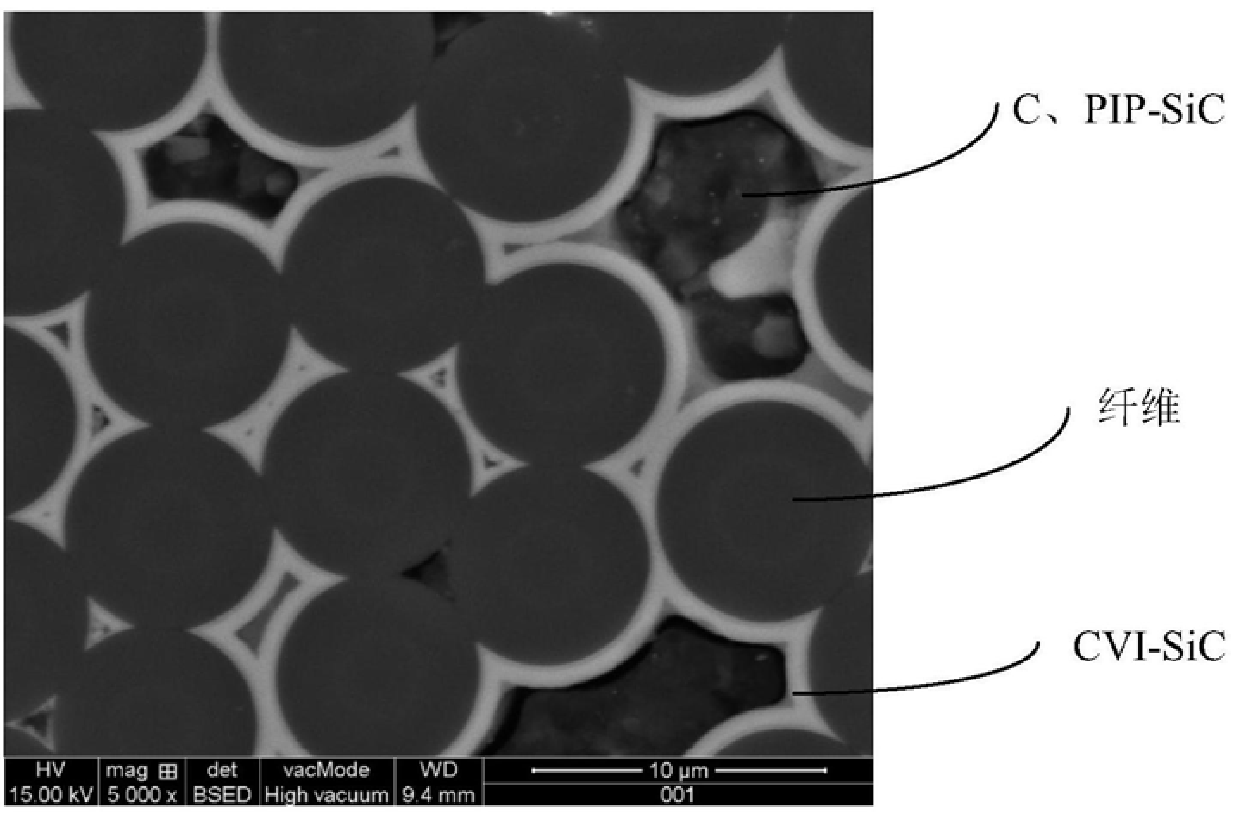

The invention discloses a method for preparing a fiber-reinforced ceramic matrix composite material with a low thermal expansion coefficient, comprising: firstly, carrying out structural weaving of a fiber preform, and the material of the fiber preform is carbon fiber or silicon carbide fiber, or a combination of the two ; secondly, the interfacial phase is prepared on the surface of the fiber preform; thirdly, the chemical vapor deposition process is used first, and then the fiber preform is densified by the impregnation and cracking process of the organic precursor. The invention can obtain the fiber-reinforced ceramic matrix composite material with low coefficient of thermal expansion.

Description

A kind of preparation method of fiber-reinforced ceramic matrix composite material with low thermal expansion coefficient Technical field [0001] The present invention relates to the technical field of ceramic matrix composite preparation, in particular to a fiber augmenter with a low coefficient of thermal expansion A method for preparing a strong ceramic matrix composite. Background technique Along with the rapid development of space technology, my country's space exploration depth and breadth are improving rapidly, and this is to space remote Sensitive detection systems put forward higher and higher requirements. The core of the space remote sensing detection system is the optical system, which is mainly composed of Composed of primary reflector, secondary reflector and camera barrel. The camera lens barrel is one of the very important components, and its front end supports Supporting the secondary reflector, the rear end is directly connected with the primary mirr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C16/32C04B35/622C04B35/80

Inventor 董绍明周海军张翔宇高乐王震何平刘猛

Owner SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com