Uranium and fluorine-containing tail gas leaching and eluent regeneration process

An eluent and elution technology, applied in the field of uranium chemical industry, can solve the problems of polluting the surrounding water source, loss, economic loss, etc., to achieve good social benefits and reduce the effect of impact.

Active Publication Date: 2011-12-07

CNNC LANZHOU URANIUM ENRICHMENT

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The generation of a large amount of low-level radioactive liquid waste, waste residue will directly bring the adverse effect of two aspects: 1) pollute surrounding water source

and the environment, causing harm to biological organisms; 2) There is a problem of uranium resource loss. Due to the difficulty in mining and extraction of uranium, uranium

The loss of resources will cause certain economic losses

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0031] UF6+H2O=UO2F2+4HF

[0038] KHCO3+KOH=K2CO3+H2O

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

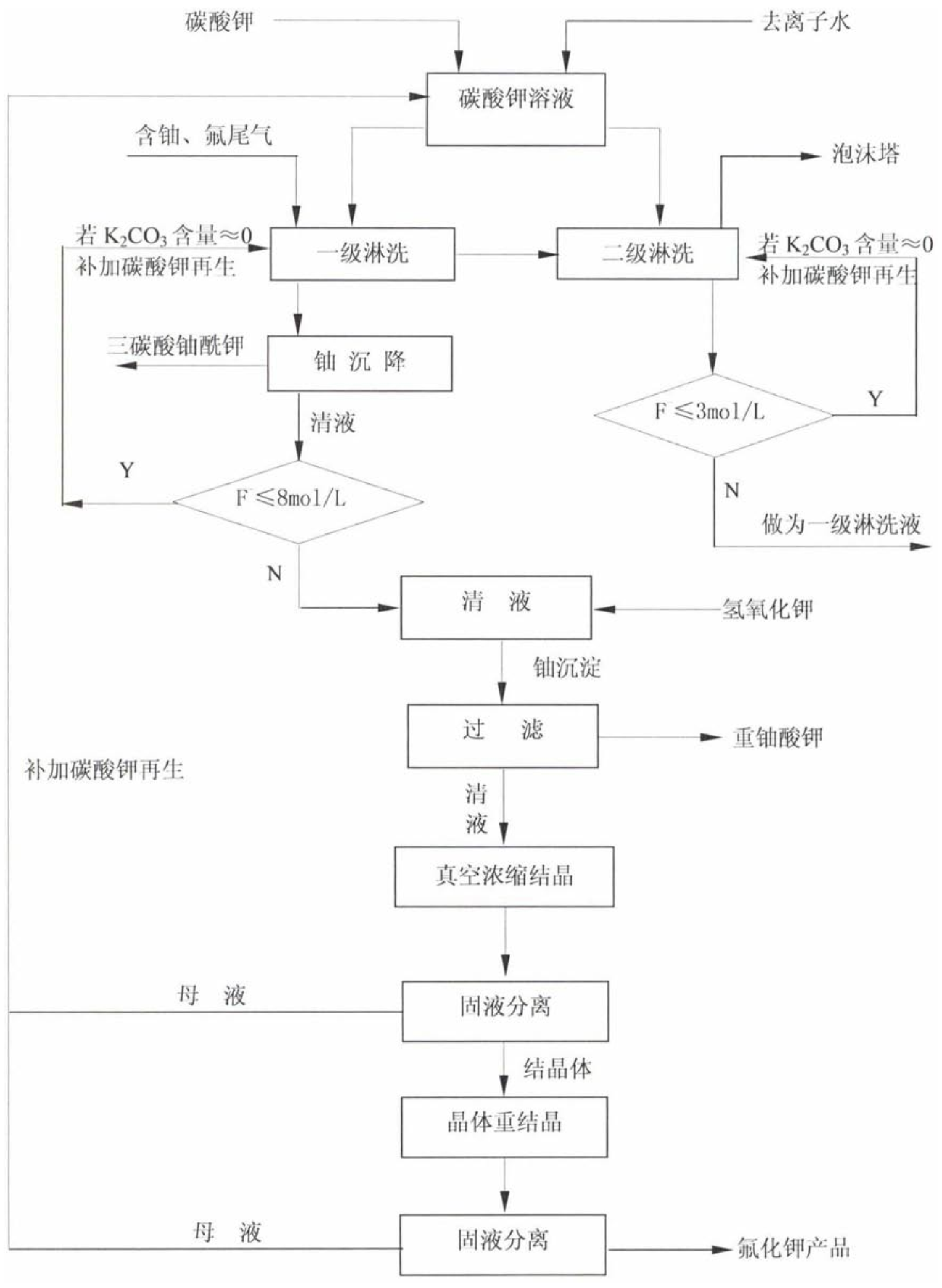

The invention relates to a process for treating uranium and fluorine-containing tail gas and waste liquid in the field of uranium chemical industry, in particular to a uranium- and fluorine-containing tail gas leaching and eluent regeneration process, which is carried out in sequence as follows: (1) K2CO3 solution is used for leaching Tail gas containing uranium and fluorine; (2) Potassium uranyl tricarbonate is separated by sedimentation. If the mass percentage concentration of K2CO3 in the resulting clear liquid is ≈0 and the concentration of KF is >8mol / l, add KOH to the clear liquid to generate diuranic acid Potassium precipitation; (3) Potassium diuranate precipitate is separated by filtration, and the obtained clear liquid is crystallized, and the crystal is KF crystal. The process of the invention can reduce the impact of radioactive waste on the environment, and has good social benefits; the closed loop of the eluent avoids the loss of uranium elements, saves resources, and recycles fluorine ions in the form of KF by-products to achieve It achieves the purpose of "turning waste into treasure" and has certain economic benefits.

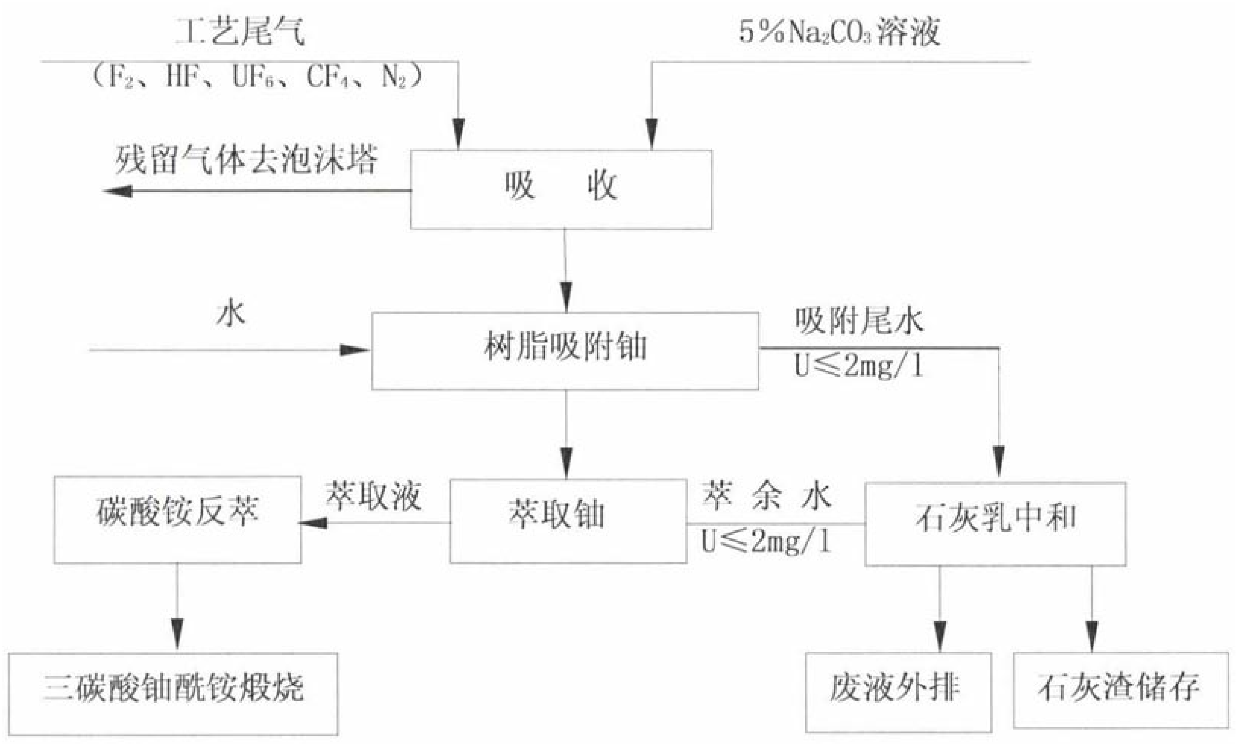

Description

Uranium and fluorine-containing tail gas leaching and eluent regeneration process technical field The present invention relates to uranium chemical industry field containing uranium, fluorine tail gas and waste liquid treatment process, be specifically related to a kind of uranium-containing, fluorine tail gas Rinse and eluent regeneration process. Background technique In uranium tetrafluoride to uranium hexafluoride conversion process, the main component of the process tail gas that produces is a large amount of nitrogen and harmful excess fluorine gas, a small amount of hydrogen fluoride gas and a small amount of uranium hexafluoride gas that has not been condensed in time, when processing the At present, about 5% sodium carbonate solution is used as the eluent to purify the exhaust gas containing uranium and fluorine. Dang shower After the concentration of uranium and fluorine ions in the washing solution reaches the specified value, the washing solution is sent ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G21F9/02B01D53/78C01G43/06C01B7/19

Inventor 刘增荣张习林王方太张改成

Owner CNNC LANZHOU URANIUM ENRICHMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com