Method for reducing trans fatty acid in high temperature oil

A technology for trans fatty acids and oils, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of reducing the sensory quality of fried food, reducing the oxygen content of oil, and insufficient frying time, and achieves good application value and Market prospects, the effect of preventing oxidative rancidity, and reducing human cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

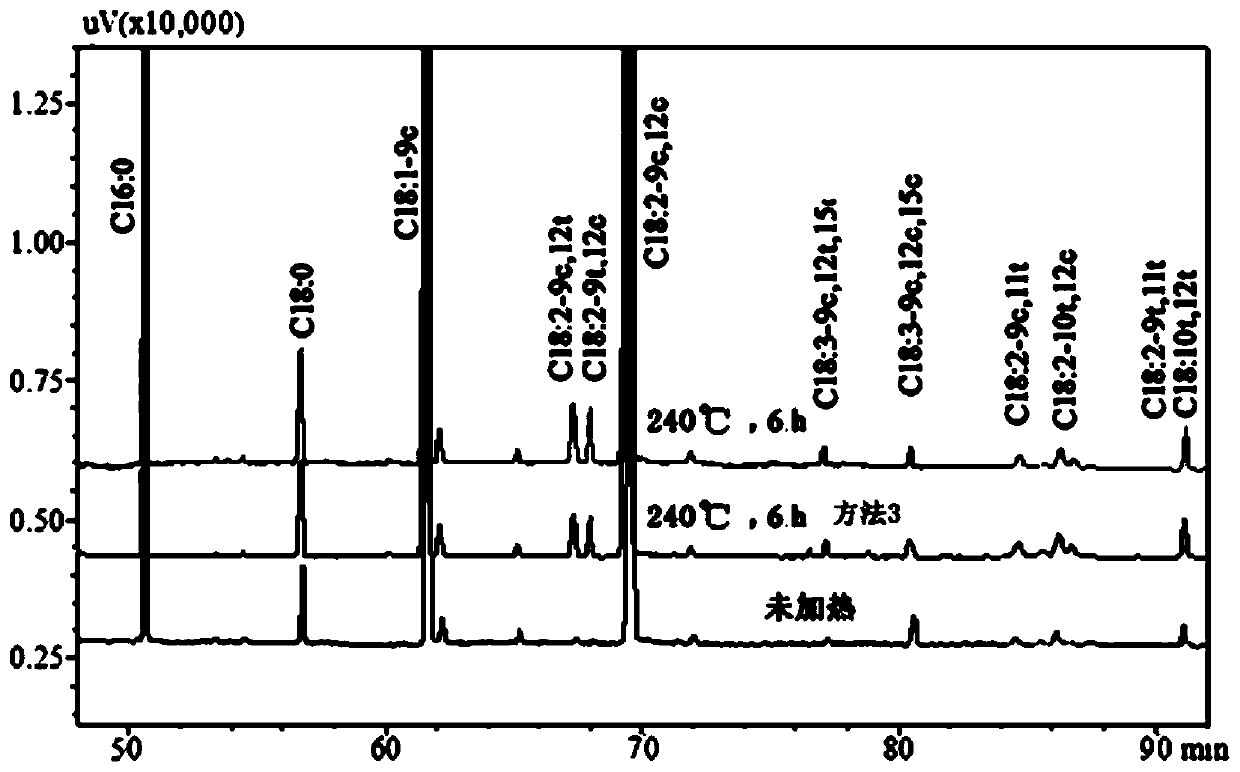

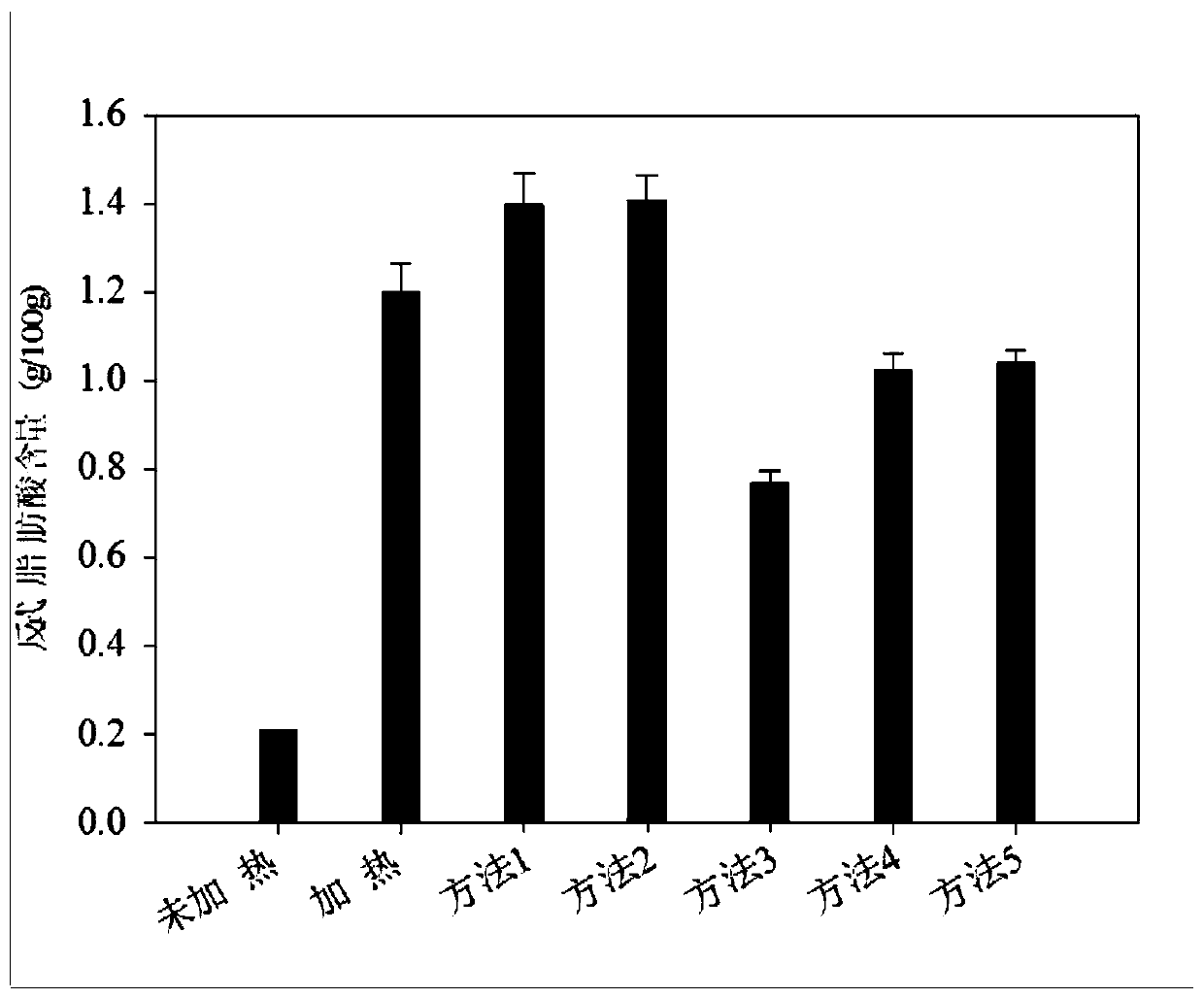

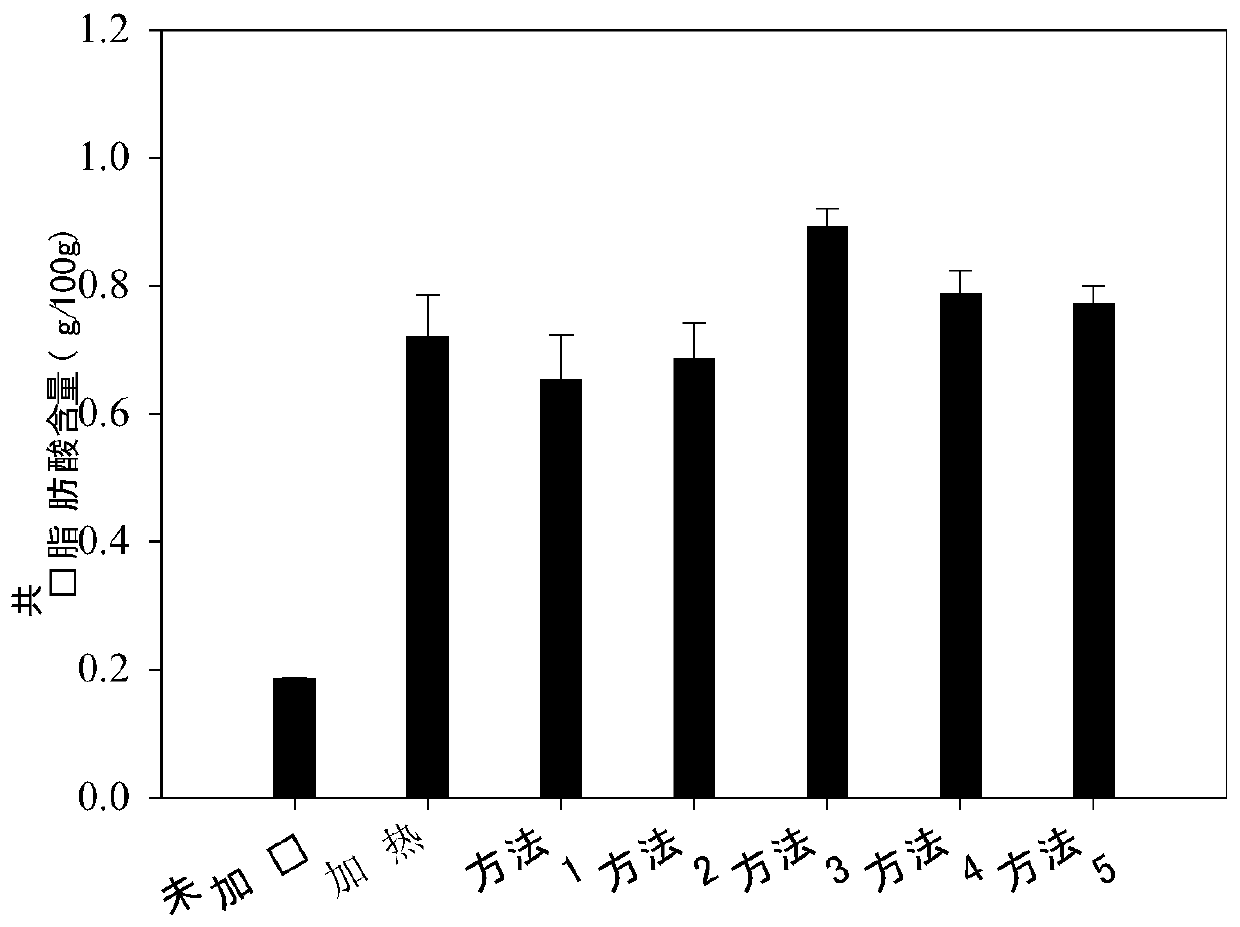

Embodiment 1

[0040] Step 1, take L-ascorbyl palmitate, vitamin E, carnosic acid oil and fat-soluble tea polyphenols (method 1) by mass percentage 0.02%; Vitamin E, carnosic acid oil, fat-soluble tea polyphenols and L - Ascorbyl palmitate (method 2); carnosic acid, fat-soluble polyphenols, L-ascorbyl palmitate, and vitamin E (method 3); fat-soluble polyphenols, L-ascorbyl palmitate, vitamin E, and Carnosic acid (method 4) was added to the corn oil in the order of weighing, and each addition was shaken at 4000rpm for 5 minutes before adding the next one and fully mixed. The mass percentages are all 0.02% L-ascorbyl palmitate, vitamin E, carnosic acid oil and fat-soluble tea polyphenols, first mix and then join in the corn oil, after mixing, obtain the corn oil with additives (method 5 ), the corn oil without additives is also subjected to the same shock, as a blank comparison sample;

[0041] Step 2. Weigh 2g of corn oil with additives and a blank reference sample in 4mL ampoules, seal the ...

Embodiment 2

[0045] Step 1. First weigh carnosic acid according to 0.02% by mass percentage, add it to a container containing corn oil, and shake it for 5 minutes under the condition of 4000rpm, then add 0.02% fat-soluble tea polyphenol, 0.02% L - Ascorbyl palmitate and 0.02% vitamin E are added to the container of corn oil, and each additive is firstly shaken at 4000rpm for 5 minutes, and then the next additive is added, fully mixed, and the additive is obtained. Corn oil (method 3), while the corn oil without additives is also subjected to the same shock, as a blank comparison sample;

[0046] Step 2. Weigh 2g of corn oil with additives and a blank reference sample in 4mL ampoules, seal the seal (with air at the top), place the ampoules in an oil bath, and place them at a temperature of 240°C Heating for 6 hours, start timing when the oil temperature reaches the set temperature, the heating temperature error is controlled at ±2°C, take it out and cool to room temperature;

[0047] Step ...

Embodiment 3

[0050] Step 1. First weigh the fat-soluble tea polyphenols according to 0.01% by mass percentage, add them into a container containing corn oil, and shake them for 5 minutes under the condition of 4000rpm, then successively add 0.01% by mass percentage of L-ascorbyl palmitate, Add 0.02% vitamin E and 0.01% carnosic acid oil to the container containing corn oil, shake for 5 minutes at 4000rpm for each additive added, then add the next additive, and mix well to obtain the additive corn oil (method 4), the corn oil without additives is also subjected to the same shock as a blank comparison sample;

[0051] Step 2. Weigh 2g of corn oil with additives and a blank reference sample in 4mL ampoules, seal the seal (with air at the top), place the ampoules in an oil bath, and place them at a temperature of 240°C Heating for 6 hours, start timing when the oil temperature reaches the set temperature, the heating temperature error is controlled at ±2°C, take it out and cool to room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com