Composite extrusion roller, and preparation method thereof

A technology of composite extrusion and reinforced composite layer, which is applied in the direction of grain processing, etc., can solve the problems of increasing the manufacturing cost of roller presses, high carbide costs, and complicated preparation processes, so as to save costs, improve wear resistance, and simplify production The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

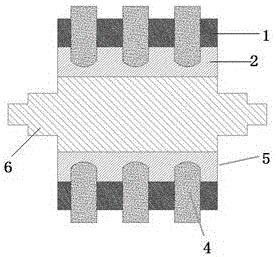

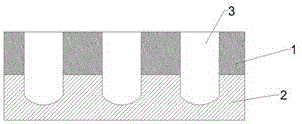

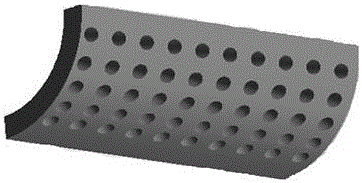

[0027] The composite extrusion roller described in this embodiment includes a wear-resistant stud 4, a roller sleeve 5, and a roller body 6. The outer surface of the roller body 6 is covered with a roller sleeve 5, and the roller sleeve 5 is composited by a metal matrix layer 2 and a ceramic reinforcement. layer 1, the metal matrix layer 2 is located on the side close to the roller body 6, a plurality of honeycomb holes 3 are arranged on the outer circumference of the roller sleeve 5, and the wear-resistant studs 4 are assembled into the honeycomb holes 3 through interference fit; the metal The thickness of the matrix layer 2 is 50 mm, the thickness of the ceramic reinforced composite layer 1 is 10 mm, the depth of the honeycomb holes 3 is 20 mm; the diameter of the honeycomb holes 3 is 8 mm, and the height of the wear-resistant studs is 25 mm; the honeycomb holes 3 are equidistantly arranged , honeycomb hole spacing 20mm, such as Figure 1~3 shown.

[0028] The preparation m...

Embodiment 2

[0033] The composite extrusion roller described in this embodiment includes a wear-resistant stud 4, a roller sleeve 5, and a roller body 6. The outer surface of the roller body 6 is covered with a roller sleeve 5, and the roller sleeve 5 is composited by a metal matrix layer 2 and a ceramic reinforcement. layer 1, the metal matrix layer 2 is located on the side close to the roller body 6, a plurality of honeycomb holes 3 are arranged on the outer circumference of the roller sleeve 5, and the wear-resistant studs 4 are assembled into the honeycomb holes 3 through interference fit; the metal The thickness of the base layer 2 is 120mm, the thickness of the ceramic reinforced composite layer 1 is 25mm, the depth of the honeycomb holes 3 is 30mm; the diameter of the honeycomb holes 3 is 15mm, and the height of the wear-resistant studs is 40mm; the honeycomb holes 3 are equidistantly arranged , honeycomb hole spacing 30mm, such as Figure 1~3 shown.

[0034] The preparation method...

Embodiment 3

[0039] The composite extrusion roller described in this embodiment includes a wear-resistant stud 4, a roller sleeve 5, and a roller body 6. The outer surface of the roller body 6 is covered with a roller sleeve 5, and the roller sleeve 5 is composited by a metal matrix layer 2 and a ceramic reinforcement. layer 1, the metal matrix layer 2 is located on the side close to the roller body 6, a plurality of honeycomb holes 3 are arranged on the outer circumference of the roller sleeve 5, and the wear-resistant studs 4 are assembled into the honeycomb holes 3 through interference fit; the metal The thickness of the matrix layer 2 is 80mm, the thickness of the ceramic reinforced composite layer 1 is 30mm, the depth of the honeycomb holes 3 is 50mm; the diameter of the honeycomb holes 3 is 20mm, and the height of the wear-resistant studs is 30mm; the honeycomb holes 3 are equidistantly arranged , honeycomb hole spacing 40mm, such as Figure 1~3 shown.

[0040] The preparation metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com