Processing technique for pin key

A processing technology and pin key technology, applied in the field of pin key processing technology, can solve the problems of difficulty in grasping and controlling the size, etc., and achieve the effect of good product effect, good appearance and surface quality, and reduction of production cost cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further illustrate the inventive concept of the present invention, the specific embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings:

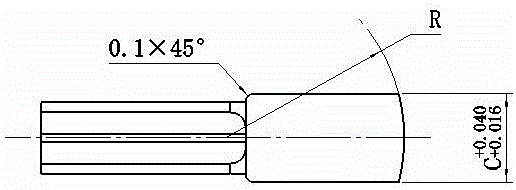

[0020] Such as Figure 1 to Figure 5 Shown, a kind of processing technology method of pin key of the present invention, it comprises the following steps:

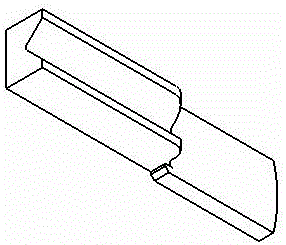

[0021] a. Prefabricated blanks: select stainless steel materials, prefabricate the processed pin key outer contour blanks in advance through ordinary machine tools or CNC machining centers, and ensure their total length requirements;

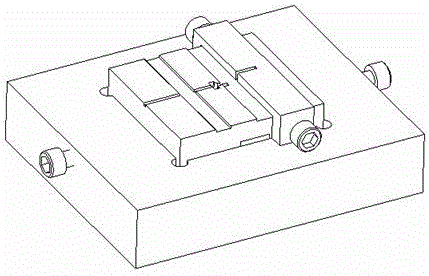

[0022] b. Installing the mould: fix the lower mold structure of the forming mold on the machine tool, and the other corresponding movable mold is the upper mold structure;

[0023] c. Blank clamping: clamp the prefabricated pin key blank on the forming mold;

[0024] d. Processing and forming: the blank is firstly extruded through the upper die of the forming die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com