Plastic crossbeam pipe column structure and plastic injecting and forming method thereof

A technology of beam tube and column structure, applied in the field of auto parts, can solve the problems of heavy weight, no application of light weight, small cost and high cost, and achieve excellent strength and rigidity, low warpage and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

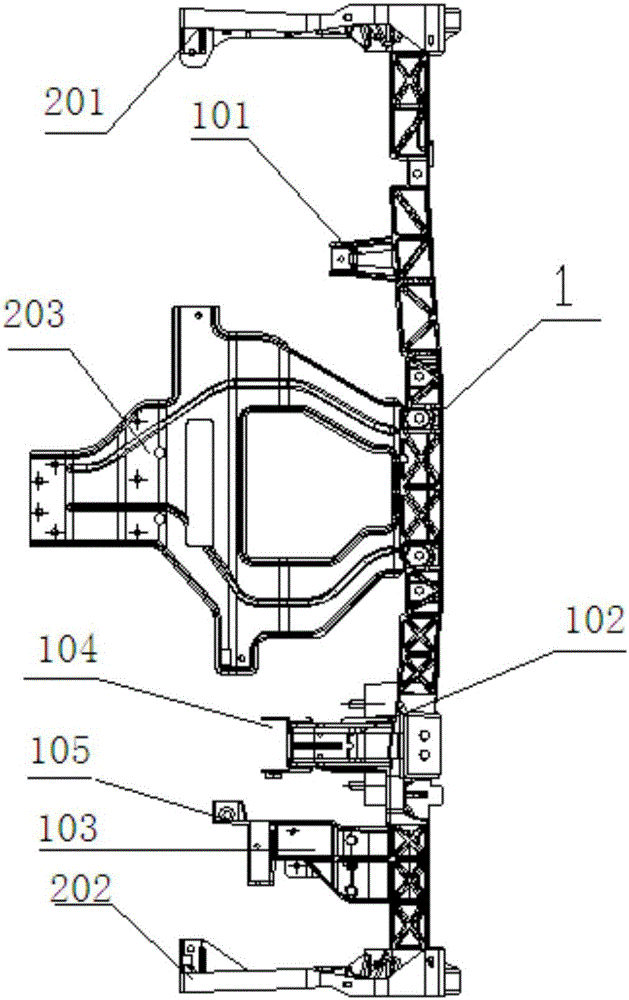

[0028] refer to figure 1 As shown, a plastic beam pipe column structure is disclosed in this embodiment, which includes: a pipe beam 1, a first connecting piece 101, a second connecting piece 102, and a third connecting piece 103 are arranged on the above-mentioned pipe beam 1, and the above-mentioned The first connecting piece 101, the second connecting piece 102, and the third connecting piece 103 are on the same side of the above-mentioned pipe beam 1, and the above-mentioned first connecting piece 101, the second connecting piece 102, the third connecting piece 103 and the above-mentioned pipe beam 1 The same material, and one-piece molding.

[0029] The first connecting piece 101 , the second connecting piece 102 , and the third connecting piece 103 are used to connect central control instruments or components, and a limiting hole is provided at the free end of the first connecting piece 101 .

[0030] A plurality of blind rivet bolts are arranged on the second connectin...

Embodiment 2

[0035] In this embodiment, the material of the first connector 101, the second connector 102, the third connector 103, and the pipe beam 1 is GVL-6H, and GVL-6H includes aromatic nylon and long fibers, and the material of GVL-6H Young's modulus is 22000MPa, Poisson's ratio is 0.4, density is 1.69.

[0036] Carry out injection molding to the beam column structure in embodiment 1, comprise the following steps:

[0037] S101 Mix and plasticize various raw materials in the material GVL-6H;

[0038] S102 melts the plasticized raw materials and forms a polymer film through a die;

[0039] S103 sends the material into the twin-screw extruder for extrusion;

[0040] S104 Press the mixed material extruded from the twin-screw extruder into the injection mold for integral injection molding.

[0041] The basic pipe beam and support part of the above-mentioned beam and column structure adopts an integral molding injection molding process. The structure has excellent strength and rigidit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com