Ageing device for producing high-grade nanometer calcium carbonate

A technology of nano-calcium carbonate and aging device, which is applied in the direction of nanotechnology, calcium carbonate/strontium/barium, and nanotechnology for materials and surface science, which can solve problems such as tank corrosion and water resource waste, and achieve treatment The effect of large quantity, improving production efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

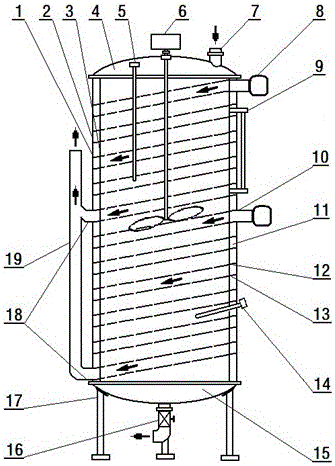

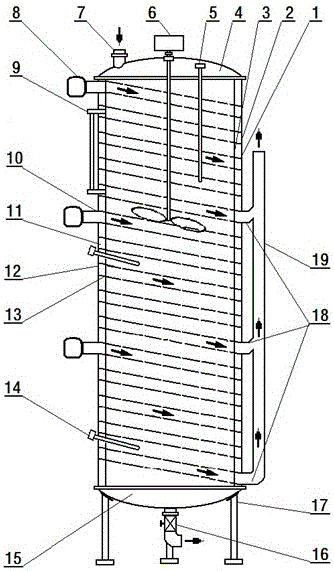

[0031] as attached figure 1 Shown, a kind of aging device that is used to produce high-grade nano calcium carbonate, its structure is made of aging tank 1, mixer 6, spiral pipeline 11 and blower fan 8, and described aging tank 1 is provided with outer tank body 2 and The inner tank body 3, the aging tank 1 is also provided with an upper head 4 and a lower head 15, the spiral pipeline 11 is arranged between the outer tank body 2 and the inner tank body 3, and the agitator 6 is fixed on the aging On the upper head 4 of the tank 1 , the fan 8 is connected to the air inlet 10 of the spiral duct 11 .

[0032] Further, two spiral pipes 11 are provided, and each spiral pipe 11 is arranged 5-7 times around the aging tank 1 in a clockwise direction. The outer tank body 2 and the inner tank body 3 of the tank 1 are formed by welding, and the heat of the aged slurry is taken away in time by utilizing the directional flow of air.

[0033] Further, the exhaust port 18 of the spiral duct ...

Embodiment 2

[0040] An aging device for producing high-grade nano-calcium carbonate, its structure is mainly composed of an aging tank 1, a mixer 6, a spiral pipeline 11 and a fan 8, and the aging tank 1 is provided with an outer tank body 2 and an inner tank body 3. The aging tank 1 is also provided with an upper head 4 and a lower head 15, the spiral pipeline 11 is arranged between the outer tank body 2 and the inner tank body 3, and the agitator 6 is fixed on the bottom of the aging tank 1 On the upper head 4 , the fan 8 is connected to the air inlet 10 of the spiral duct 11 .

[0041] Further, there are 3 spiral pipes 11, and each spiral pipe 11 is arranged 8 circles around the aging tank 1 in the counterclockwise direction. 1. The outer tank body 2 and the inner tank body 3 are formed by welding, and the directional flow of air is used to take away the heat of the aged slurry in time.

[0042] Further, the exhaust port 18 of the spiral duct 11 is connected with an exhaust pipe 19 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com