Preparation method of deep sea glass buoyage and moulding device thereof

A glass and floating ball technology, applied in the field of deep-sea exploration, can solve the problems such as the failure of the submersible mark system to be successfully recovered, and achieve the effects of simple production process, convenient operation and control, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better clearly express the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

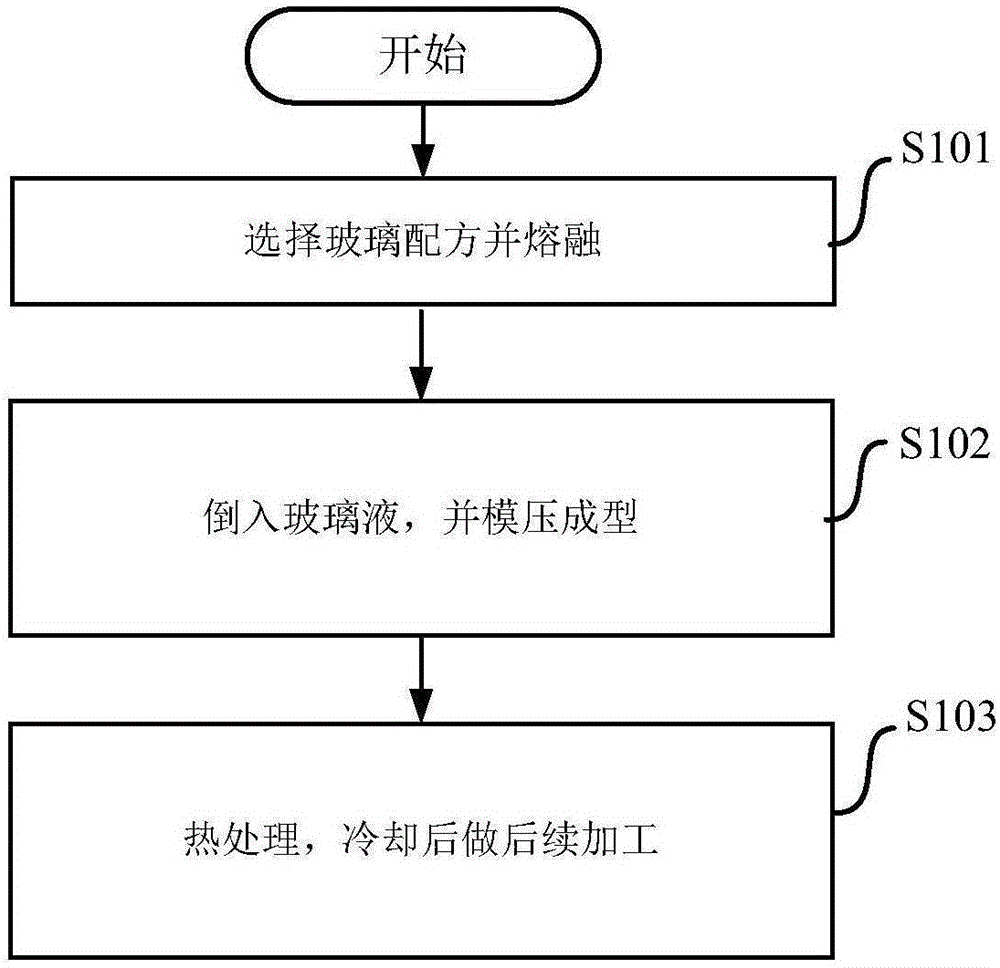

[0016] figure 1 A method for preparing a deep-sea glass buoy according to a specific embodiment of the present invention is shown. In step S101, a glass component suitable for use in a deep-sea environment is selected and melted into high-temperature molten glass according to the formula. For example, the weight percent range of the above-mentioned glass components is: silicon dioxide: 75-85%; boron oxide: 8-15%; sodium oxide+potassium oxide: 1-5%; aluminum oxide 1-4%; other iron oxide, Magnesium oxide, etc. 0-1%.

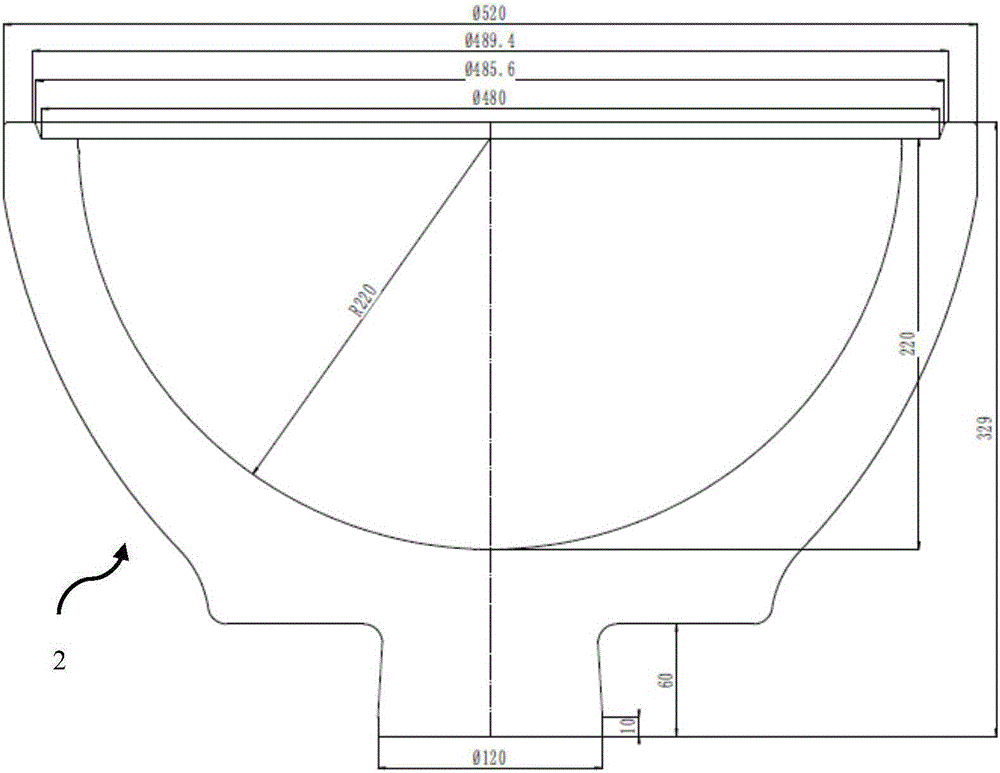

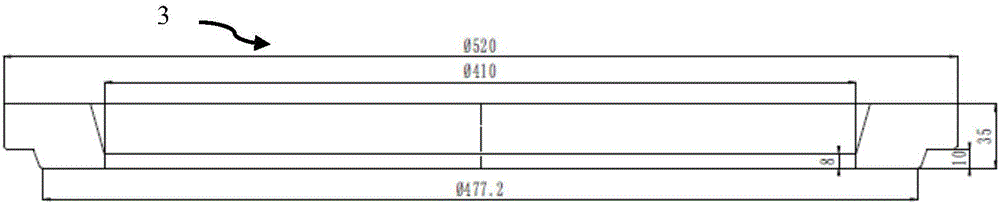

[0017] In step S102, the molten glass is poured into the preheated mold, the punch is pressed down and rolled into a glass float hemisphere, and the rolled glass float hemisphere is quickly moved into an annealing kiln for annealing treatment step . Specifically, it is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com