A display panel and method of making the same

A display panel and display area technology, which is applied in the direction of identification devices, instruments, semiconductor devices, etc., can solve the problems of increasing the cost of the mask, abnormal display, easy to break, etc., and achieve the effect of saving the cost of the mask and prolonging the etching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

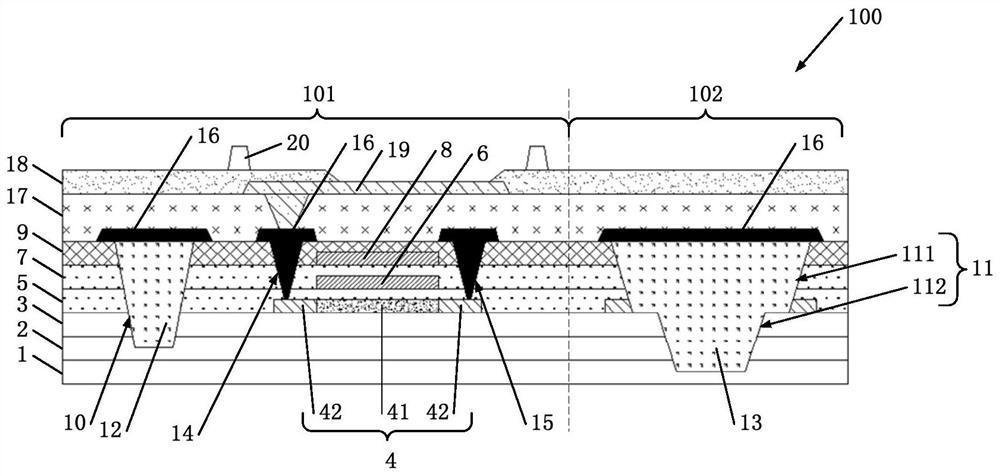

[0043] like figure 1As shown, a display panel 100 is defined with a display area 101 and a non-display area 102, and the non-display area 102 has a bending area. The display panel 100 includes: a substrate 1 , a barrier layer 2 , a buffer layer 3 , an active layer 4 , a first gate insulating layer 5 , a first gate layer 6 , a second gate insulating layer 7 , and a second gate Polar layer 8 and interlayer insulating layer 9 .

[0044] like figure 1 As shown, the substrate 1 may include a first substrate, an intermediate layer and a second substrate. Wherein, the constituent materials of the first substrate and the second substrate can be selected from polyimide, and the first substrate and the second substrate made by this can have good flexibility. The composition material of the intermediate layer can be SiO2 or SiNx, or can be a laminated structure of SiO2 and SiNx. The intermediate layer prepared by this has good water and oxygen resistance, and can also improve the perf...

Embodiment 2

[0058] This embodiment provides a manufacturing method for manufacturing the display panel 100 involved in the present invention.

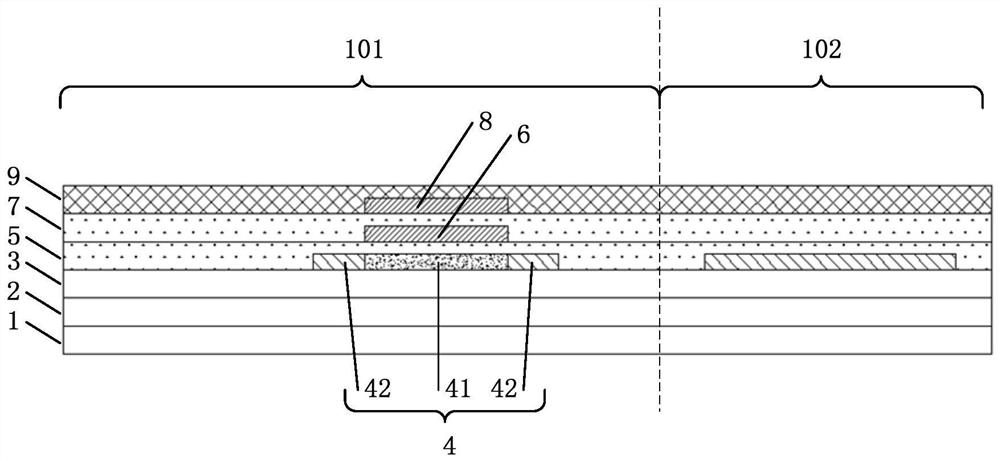

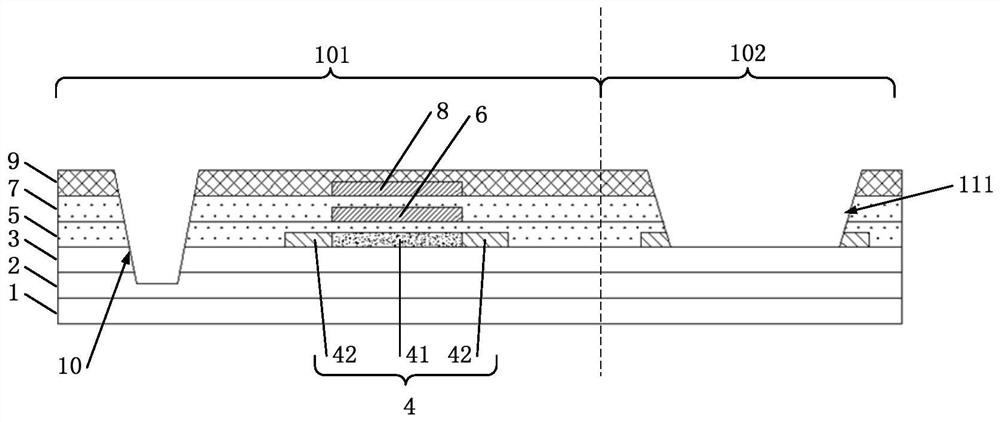

[0059] like figure 2 As shown, in S1, a substrate 1 is provided, and the display panel 100 to be prepared is defined into a display area 101 and a non-display area 102, and the non-display area 102 has a bending area; S2, barriers are sequentially prepared on the substrate 1 Layer 2 , buffer layer 3 , active layer 4 , interlayer insulating layer 9 .

[0060] like figure 2 As shown, the active layer 4 is disposed on the display area 101 and the buffer layer 3 in the bending area. Since the depth of the first groove 10 is greater than the thickness of the first groove body 111 of the second groove 11, and the etching rate of the active layer 4 is slower than that of the film layer disposed thereon, the buffer layer in the bending region is The active layer 4 is provided on the 3 , so that the first mask can meet the depth requirements of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com