A kind of warm pressure fuse and preparation method thereof

A fuse, temperature and pressure technology, applied in the direction of detonating cord, offensive equipment, explosive processing equipment, etc., can solve the problems of high mechanical sensitivity of black powder, easy moisture deterioration of black powder, accidental combustion, etc., to achieve green blasting operation, economical and reasonable blasting operation, and the effect of reducing fluctuations in burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

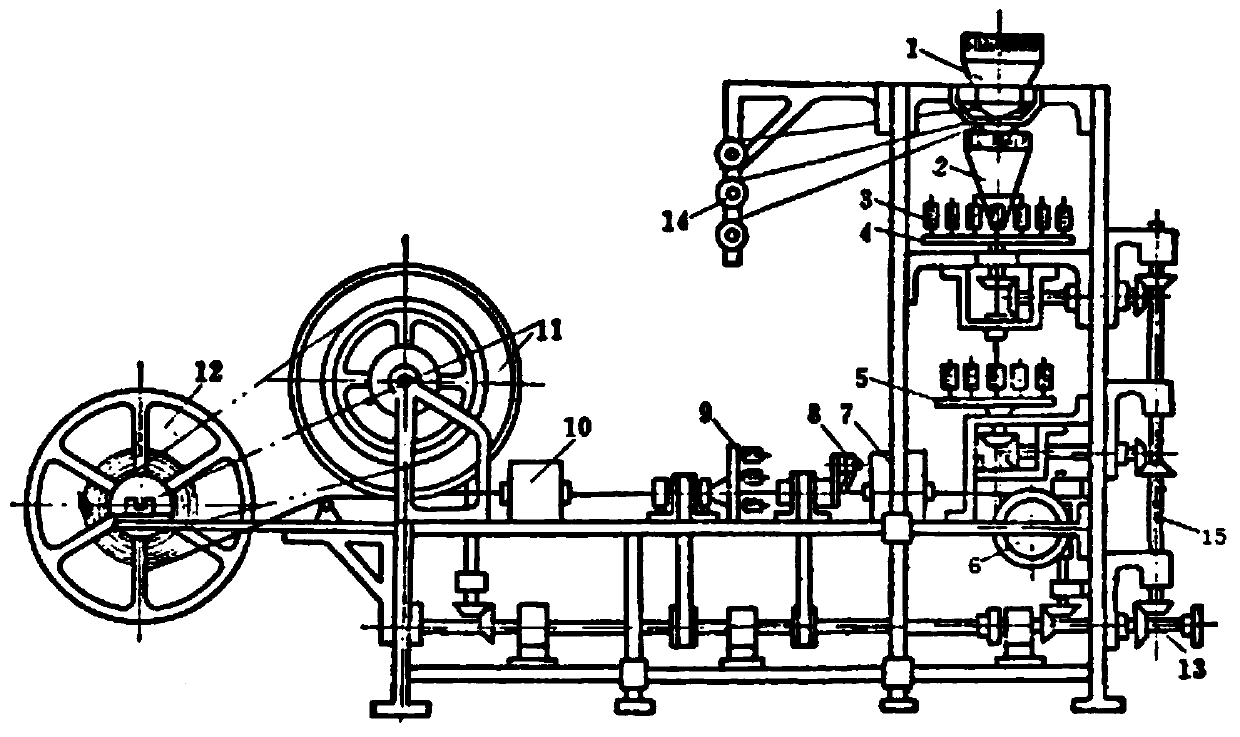

Image

Examples

Embodiment 1

[0043] This embodiment provides a thermo-pressure fuse, which includes a cord core and a cord shell covering the cord core. The cord core includes a thermo-pressure powder core and two core wires located in the warm-pressure powder core , The material of the core thread is cotton fiber;

[0044] The cable shell includes an inner layer line, a first paper strip layer, a middle layer line, an asphalt layer, a second paper strip layer and a paint layer arranged in sequence from the inside to the outside; wherein, the inner layer line and the middle layer line are both flax Fiber, the material of the first paper strip layer and the second paper strip layer is fuse paper, the component of the asphalt layer is petroleum pitch, and the component of the coating layer is polyvinyl alcohol.

[0045] The preparation method of the warm-pressure gunpowder used in the warm-pressure gunpowder core is as follows:

[0046] (S1) Weigh 67 parts by weight of potassium nitrate and pulverize to obtain po...

Embodiment 2

[0062] This embodiment provides a thermo-pressure fuse, including a cord core and a cord shell wrapping the cord core, the cord core includes a warm-pressure gunpowder core and 5 core wires located in the warm-pressure gunpowder core The material of the core thread is flax fiber.

[0063] The cable shell includes an inner layer line, a first paper strip layer, a middle layer line, an asphalt layer, a second paper strip layer, and a paint layer sequentially arranged from the inside to the outside; wherein the inner layer line and the middle layer line are made of the same material It is cotton fiber, the materials of the first paper strip layer and the second paper strip layer are fuse paper, the component of the asphalt layer is petroleum pitch, and the component of the coating layer is polymethyl cellulose .

[0064] The preparation method of the warm-pressure gunpowder used in the warm-pressure gunpowder core is as follows:

[0065] (S1) Weigh 95 parts by weight of lead tetroxide...

Embodiment 3

[0081] This embodiment provides a thermo-pressure fuse comprising a cord core and a cord shell covering the cord core, the cord core including a thermo-pressure powder core and three core wires located in the warm-pressure powder core , The core wire is made of chemical fiber;

[0082] The cable shell includes an inner layer line, a first paper strip layer, a middle layer line, an asphalt layer, a second paper strip layer and a paint layer arranged in sequence from the inside to the outside; wherein, the inner layer line and the middle layer line are all chemical The material of the first paper strip layer and the second paper strip layer is fuse paper, the component of the asphalt layer is petroleum pitch, and the component of the coating layer is starch, clay, and talc according to the quality A mixture of 1:1:1 ratio.

[0083] The preparation method of the warm-pressure gunpowder used in the warm-pressure gunpowder core is as follows:

[0084] (S1) Weigh 80 parts by weight of ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com