A kind of thermobaric nonel and preparation method thereof

A detonator, temperature and pressure technology, applied in the field of temperature and pressure detonator and its preparation, can solve the problems of accidental explosion, failure of rock to work, high mechanical sensitivity of detonating charge, etc., to reduce the fluctuation of combustion speed, realize thorough control, The effect of green environmental protection and economical and reasonable blasting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

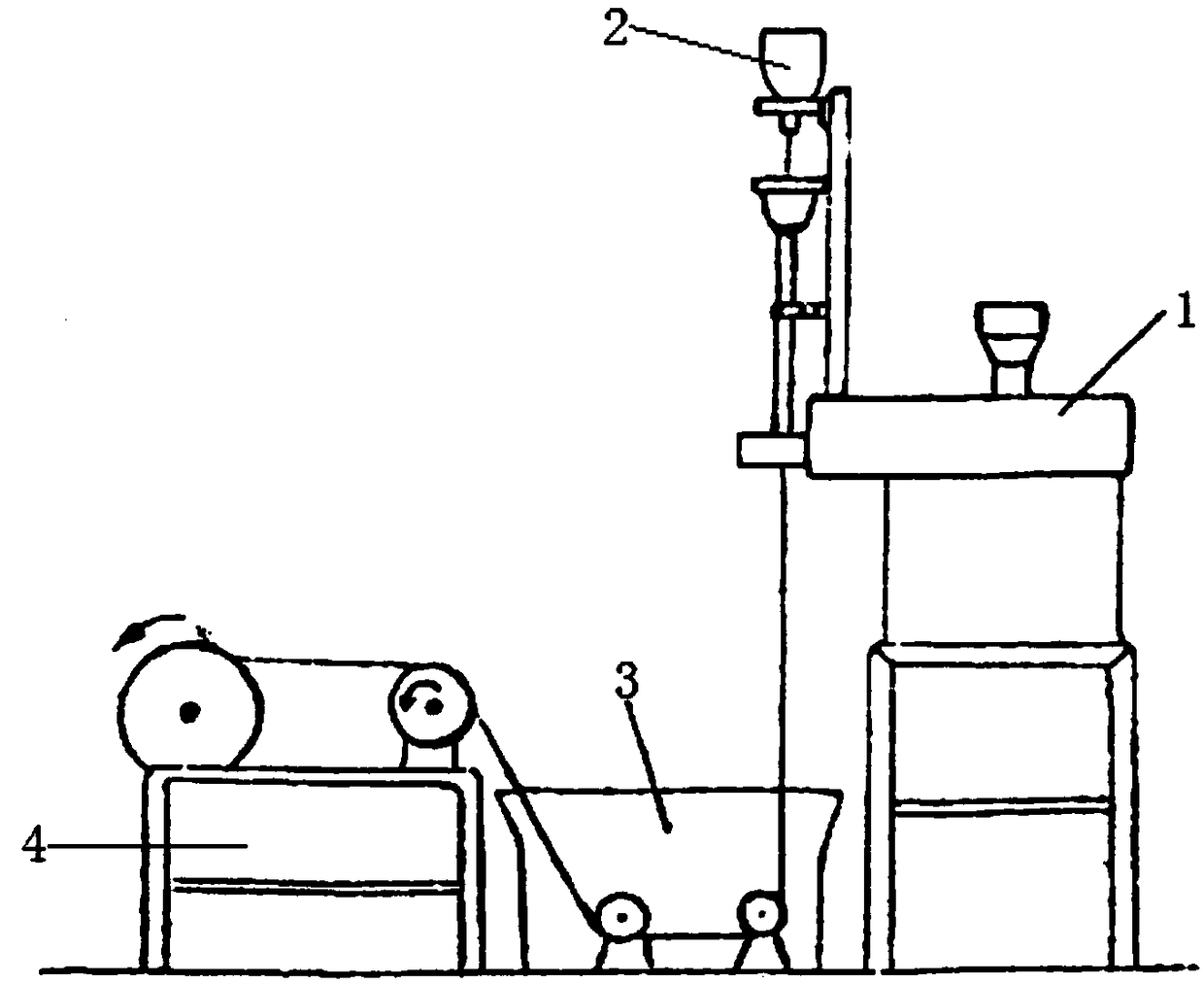

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a thermobaric detonator, which includes a double-layer composite pipe, the double-layer composite pipe includes a first plastic layer located on the outer layer, and a second plastic layer arranged close to the inner surface of the first plastic layer And an accommodating space inside the second plastic layer, the accommodating space is filled with thermobaric gunpowder; the inner diameter of the first plastic layer is 3.0 mm, and the inner diameter of the second plastic layer is 0.5 mm.

[0047] The mass of the first plastic layer accounts for 70% of the mass of the double-layer composite pipe, and the raw materials of the first plastic layer include 40 parts by weight of low-density polyethylene, 50 parts by weight of polypropylene, 1 part by weight of Hydroquinone, the vinyl alcohol of 8 weight parts and the talcum powder of 0.5 weight part;

[0048] The mass of the second plastic layer accounts for 30% of the mass of the double-layer composi...

Embodiment 2

[0069] This embodiment provides a thermobaric detonator, which includes a double-layer composite pipe, the double-layer composite pipe includes a first plastic layer located on the outer layer, and a second plastic layer arranged close to the inner surface of the first plastic layer And an accommodating space inside the second plastic layer, the accommodating space is filled with thermobaric gunpowder; the inner diameter of the first plastic layer is 5.8 mm, and the inner diameter of the second plastic layer is 0.6 mm.

[0070] The mass of the first plastic layer accounts for 90% of the mass of the double-layer composite pipe, and the raw materials of the first plastic layer include 60 parts by weight of low-density polyethylene, 30 parts by weight of polypropylene, 3 parts by weight of Hydroquinone, the vinyl alcohol of 6 weight parts and the talcum powder of 1.5 weight parts;

[0071] The mass of the second plastic layer accounts for 10% of the mass of the double-layer compo...

Embodiment 3

[0092] This embodiment provides a thermobaric detonator, which includes a double-layer composite pipe, the double-layer composite pipe includes a first plastic layer located on the outer layer, and a second plastic layer arranged close to the inner surface of the first plastic layer And an accommodating space inside the second plastic layer, the accommodating space is filled with thermobaric gunpowder; the inner diameter of the first plastic layer is 6.0 mm, and the inner diameter of the second plastic layer is 0.8 mm.

[0093] The mass of the first plastic layer accounts for 75% of the mass of the double-layer composite pipe, and the raw materials of the first plastic layer include 50 parts by weight of low-density polyethylene, 40 parts by weight of polypropylene, 2 parts by weight of Hydroquinone, the vinyl alcohol of 7 parts by weight and the talcum powder of 1.0 parts by weight;

[0094] The mass of the second plastic layer accounts for 25% of the mass of the double-layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com