Refining method for apixaban

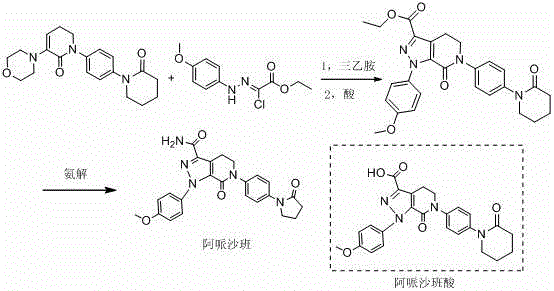

A purification method and apixaban technology, applied in the purification field of apixaban, can solve the problems of complicated operation, poor solubility, waste of energy and the like, and achieve the effects of low dissolution temperature, simple operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

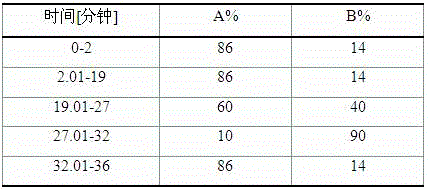

[0020] A method for refining Apixaban, the specific steps are as follows:

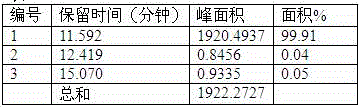

[0021] Add 14kg of dichloromethane to the 50L reaction kettle, start stirring, add 1.4kg of crude apixaban, then add 14kg of methanol, stir for 30 minutes until completely dissolved, filter out insolubles if necessary; put 2.5kg of 3wt% sodium hydroxide Add the solution into the reaction kettle, stir for 1 hour, and let stand to separate the liquid; transfer the organic layer into a 50L reaction kettle, start stirring, slowly add 28kg of n-hexane, mix well, leave it under natural conditions for 4 hours to precipitate solids, and filter; The solid was air-dried at 60° C. for 8 hours to obtain 1.3 kg of fine apixaban product. HPLC: 99.92%, Apixabanic acid 0%, H 1 NMR (d6-DMSO δ: 7.71(br, 1H), 7.51(m, 2H), 7.43(br, 1H), 7.35(m, 2H), 7.28(m, 2H), 7.00(m, 2H), 4.06 (m,2H), 3.79(s,3H), 3.58(m,2H), 3.20(m,2H), 2.39(m,2H), 1.83(m,4H).

Embodiment 2

[0023] A method for refining Apixaban, the specific steps are as follows:

[0024] At 25°C, add 25kg of dichloromethane into the 50L reaction kettle, start stirring, add 1.8kg of crude apixaban, then add 15kg of methanol, stir for 30 minutes until completely dissolved, filter out insolubles if necessary; put 6.2kg Add 3wt% sodium hydroxide solution into the reaction kettle, stir for 1 hour, let stand to separate the liquid; transfer the organic layer into a 50L reaction kettle, start stirring, slowly add 28kg cyclohexane, mix well, and place it under natural conditions for 4 hours The solid was precipitated and filtered; the solid was air-dried at 60° C. for 8 hours to obtain 1.6 kg of fine apixaban product. HPLC: 99.91%, Apixabanic acid: 0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com