High-strength non-formaldehyde adhesive used for furniture, and preparation method thereof

A high-strength, adhesive technology, used in adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of formaldehyde volatilization, exceeding the standard, and harm to residents' health, and achieve the effect of enhancing strength and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

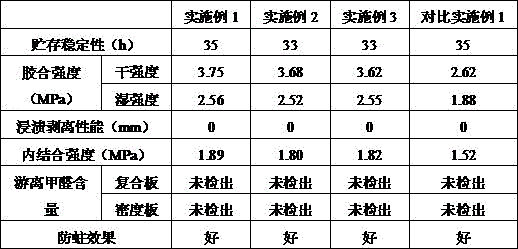

Examples

Embodiment 1

[0027] A high-strength formaldehyde-free adhesive for furniture, comprising the following components by weight percentage:

[0028] Cornstarch 25%

[0030] Acid Alpha-Amylase 3%

[0031] Guar Gum 4%

[0032] Diatomaceous earth 6%

[0033] Bamboo fiber 0.7%

[0034] Corning Hydropalat 875 0.2%

[0035] Beta-cyclodextrin 7%

[0036] water balance.

[0037] A preparation method for high-strength formaldehyde-free adhesive for furniture, comprising the following steps:

[0038] A. First adjust the starch with water to a solution with a concentration of 40%, ultrasonically treat it at 65°C for 17min, the ultrasonic frequency is 25kHz, the ultrasonic power is 125w, and filter;

[0039] B. Add acid α-amylase and adjust the pH value to 4.0-4.5, enzymolysis for 30 minutes;

[0040] C. Adjust the pH value to 7.0-7.5, add dispersant, graphene oxide and β-cyclodextrin, and stir for 30 minutes;

[0041] D. Add the remaining raw materials and stir for...

Embodiment 2

[0043] A high-strength formaldehyde-free adhesive for furniture, comprising the following components by weight percentage:

[0044] Cornstarch 20%

[0046] Acid Alpha-Amylase 5%

[0047] Guar Gum 2%

[0048] Diatomaceous earth 8%

[0049] Bamboo fiber 0.5%

[0050] Corning Hydropalat 875 0.3%

[0051] Beta-Cyclodextrin 10%

[0052] water balance.

[0053] A preparation method for high-strength formaldehyde-free adhesive for furniture, comprising the following steps:

[0054] A. First adjust the starch water to a solution with a concentration of 35%, ultrasonically treat it at 70°C for 15min, the ultrasonic frequency is 30kHz, the ultrasonic power is 120w, and filter;

[0055] B. Add acid α-amylase and adjust the pH value to 4.0-4.5, enzymatic hydrolysis for 35 minutes;

[0056] C. Adjust the pH value to 7.0-7.5, add dispersant, graphene oxide and β-cyclodextrin, and stir for 15 minutes;

[0057] D. Add the remaining raw materials and sti...

Embodiment 3

[0059] A high-strength formaldehyde-free adhesive for furniture, comprising the following components by weight percentage:

[0060] Cornstarch 30%

[0061] Graphene oxide 0.02%

[0062] Acid Alpha-Amylase 2%

[0063] Guar Gum 5%

[0064] Diatomaceous earth 3%

[0065] Bamboo fiber 1%

[0066] Corning Hydropalat 875 0.1%

[0067] Beta-Cyclodextrin 3%

[0068] water balance.

[0069] A preparation method for high-strength formaldehyde-free adhesive for furniture, comprising the following steps:

[0070] A. First adjust the starch water to a solution with a concentration of 45%, ultrasonically treat it at 60°C for 20 minutes, the ultrasonic frequency is 20kHz, and the ultrasonic power is 150w, and filter;

[0071] B. Add acid α-amylase and adjust the pH value to 4.0-4.5, enzymolysis for 25 minutes;

[0072] C. Adjust the pH value to 7.0-7.5, add dispersant, graphene oxide and β-cyclodextrin, and stir for 25 minutes;

[0073] D. Add the remaining raw materials and stir f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com