Special engine oil for improving engine oil combustion phenomenon of turbocharged engine and preparation method thereof

A turbocharger and engine technology, applied in the field of lubricating oil, can solve the problem of burning oil, etc., and achieve the effect of high flash point, reduced evaporation loss, high temperature and high shear viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

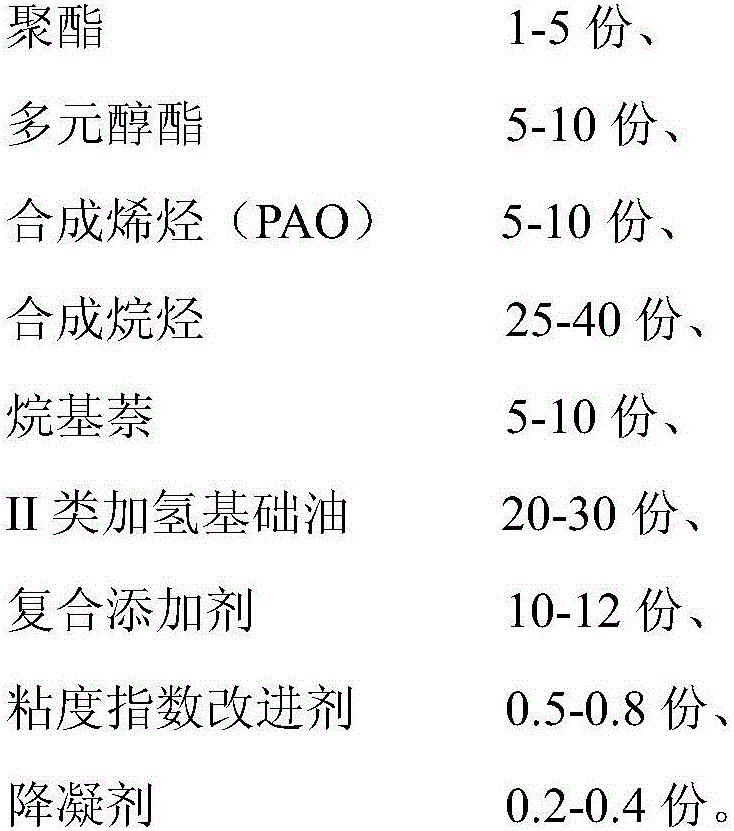

[0040] A special engine oil for improving the oil burning phenomenon of a turbocharged engine, including the following components in parts by mass:

[0041]

[0042] Among them, the kinematic viscosity of the polyester at 40°C is 100-400 centistokes, and the open flash point is not lower than 275°C.

[0043] According to above-mentioned proportioning, make following preparation:

[0044] 1) Put Class II hydrogenated base oil 150N and synthetic alkanes ShellX430 into the blending kettle through the raw material pump through the filter pump, and gradually heat up to 50°C; add viscosity index improver SV261 and stir for 15 minutes; add polyester KL135, multi-component Alcohol ester TMTC, synthetic olefin PAO6 and alkylnaphthalene AN23, stir well, keep at 55°C for 35min;

[0045] 2) Add composite additive P5810 and pour point depressant 1-248 into the blending kettle in sequence, start pulse blending, and heat at the same time, the blending temperature is 55°C, pulse blending ...

Embodiment 2

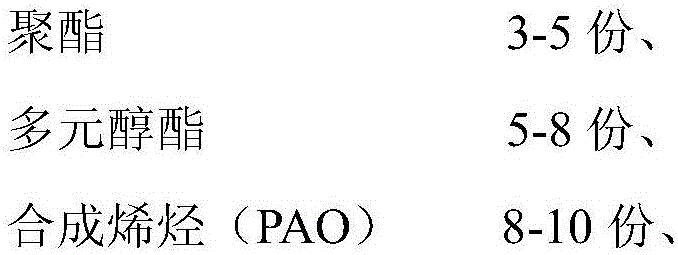

[0048] A special engine oil for improving the oil burning phenomenon of a turbocharged engine, including the following components in parts by mass:

[0049]

[0050]

[0051] Among them, the kinematic viscosity of the polyester at 40°C is 100-400 centistokes, and the open flash point is not lower than 275°C.

[0052] According to above-mentioned proportioning, make following preparation:

[0053] 1) Put Class II hydrogenated base oil 150N and synthetic alkanes Shell X430 into the blending kettle through the raw material pump through the filter pump, and gradually heat up to 55°C; add viscosity index improver SV261 and stir for 12 minutes; add polyester KL135, Polyol ester TMTC, synthetic olefin PAO6 and alkylnaphthalene AN23, stir evenly, keep at 60°C for 40min;

[0054] 2) Add composite additive P5810 and pour point depressant 1-248 into the blending kettle in sequence, start pulse blending, and heat at the same time, the blending temperature is 60°C, pulse blending fo...

Embodiment 3

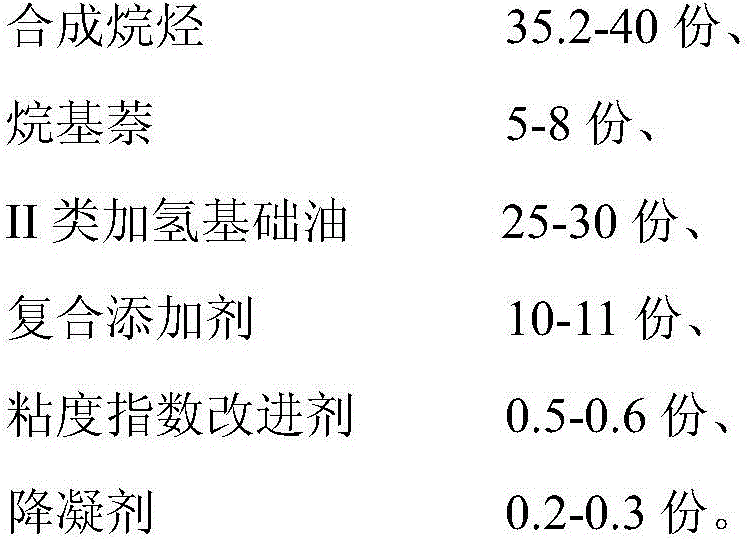

[0057]A special engine oil for improving the oil burning phenomenon of a turbocharged engine, including the following components in parts by mass:

[0058]

[0059] Among them, the kinematic viscosity of the polyester at 40°C is 100-400 centistokes, and the open flash point is not lower than 275°C.

[0060] According to above-mentioned proportioning, make following preparation:

[0061] 1) Put Type II hydrogenated base oil 6cst (Daqing) and synthetic alkanes Shell X420 into the blending kettle through the raw material pump through the filter pump, and gradually heat up to 50°C; add viscosity index improver LZ7067C, and stir for 15 minutes; add poly Ester KL115, polyol ester KL15, synthetic olefin PAO4 and alkylnaphthalene AN23, stir well, keep at 50°C for 45min;

[0062] 2) Add composite additive P5810 and pour point depressant 720P into the blending kettle in sequence, start pulse blending, and heat at the same time, the blending temperature is 50°C, pulse blending 60min;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Open flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com