Heating device for high-temperature thin film deposition

A thin film deposition and heating device technology, applied in the direction of ion implantation plating, gaseous chemical plating, coating, etc., can solve the problems affecting the surface morphology and conductivity of YBCO strips, and the discharge of electrode sheets and basebands, etc., to achieve High energy utilization rate, reduced preparation cost, and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

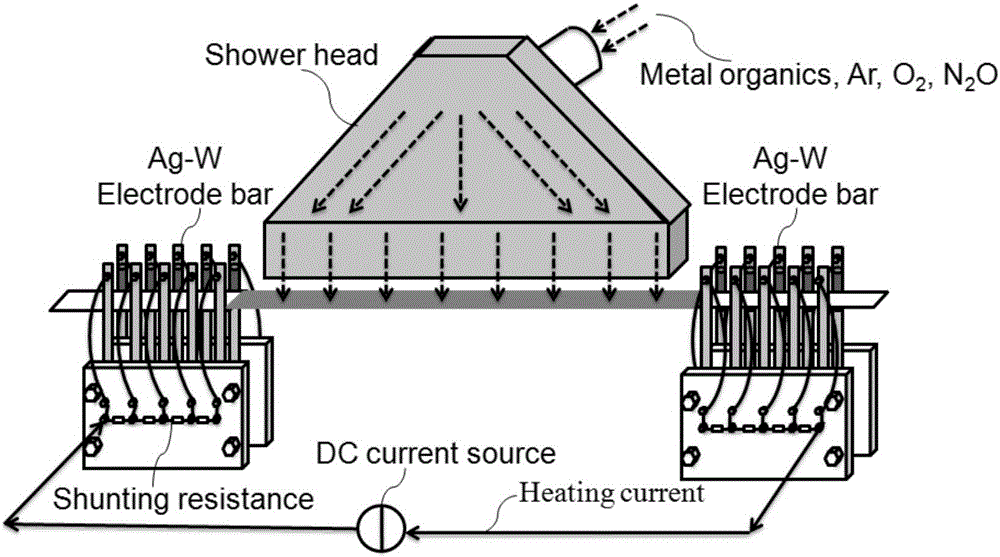

[0036] Will figure 1 The device shown is used in the second generation high-temperature superconducting coated conductor YBa 2 Cu 3 o 7-x (YBCO) film preparation. Cut a section of Hastelloy base band (LaMnO 3 / homo-epiMgO / IBAD-MgO / SDP-Y 2 o 3 / Hastelloy), grind the two sides of the metal substrate to remove the oxide deposited on the side to achieve good electrical contact, and then weld it end to end to the stainless steel traction belt by welding, and finally according to In the above embodiment, the base belt of the metal substrate is fixed, the stainless steel traction belt is connected to the winding reel, and the circuit is connected. Evacuate the growth chamber of the MOCVD system to below 1 Pa. Weigh Y(TMHD) of 128.4mg of metal organic source respectively 3 , 143mg of Gd(TMHD) 3 , 696mg of Ba(TMHD) 2 , 356.885mg of Cu(TMHD) 2 and 16....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com