A loader engine water cycle control method and system

A control method and engine technology, which is applied in the direction of machine/engine, engine components, engine starting, etc., can solve problems such as difficult replenishment, difficult atomization of diesel oil, energy loss, etc., and achieves simple and easy operation, increased cooling effect, and extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with example and accompanying drawing, it should be pointed out that following embodiment is illustrative only, and it is not intended to limit the present invention.

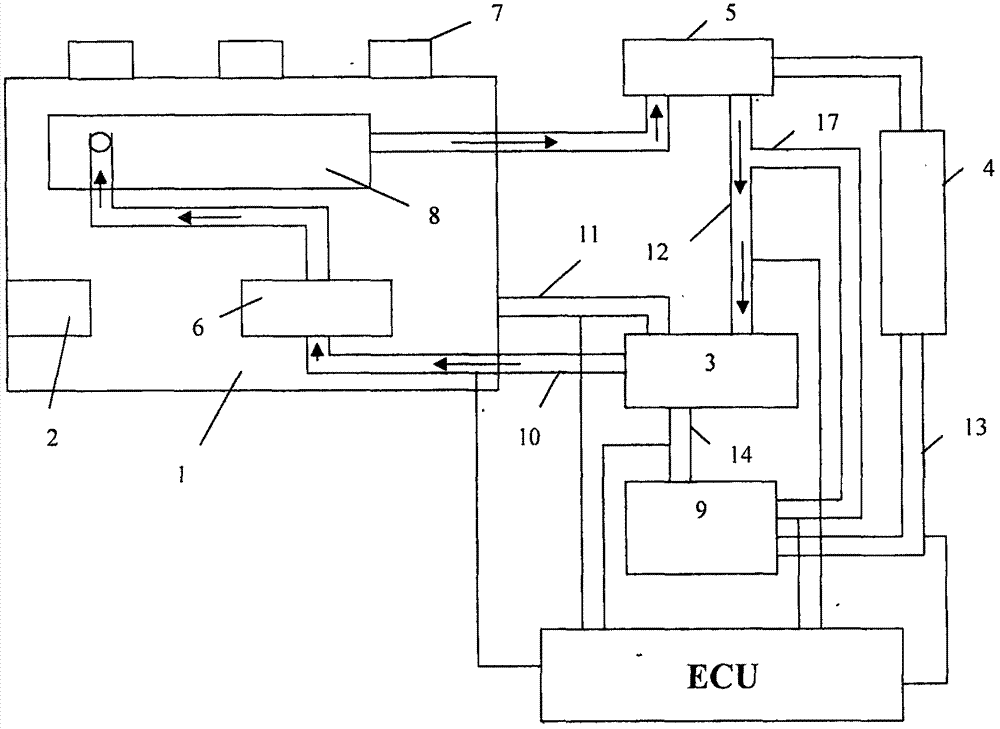

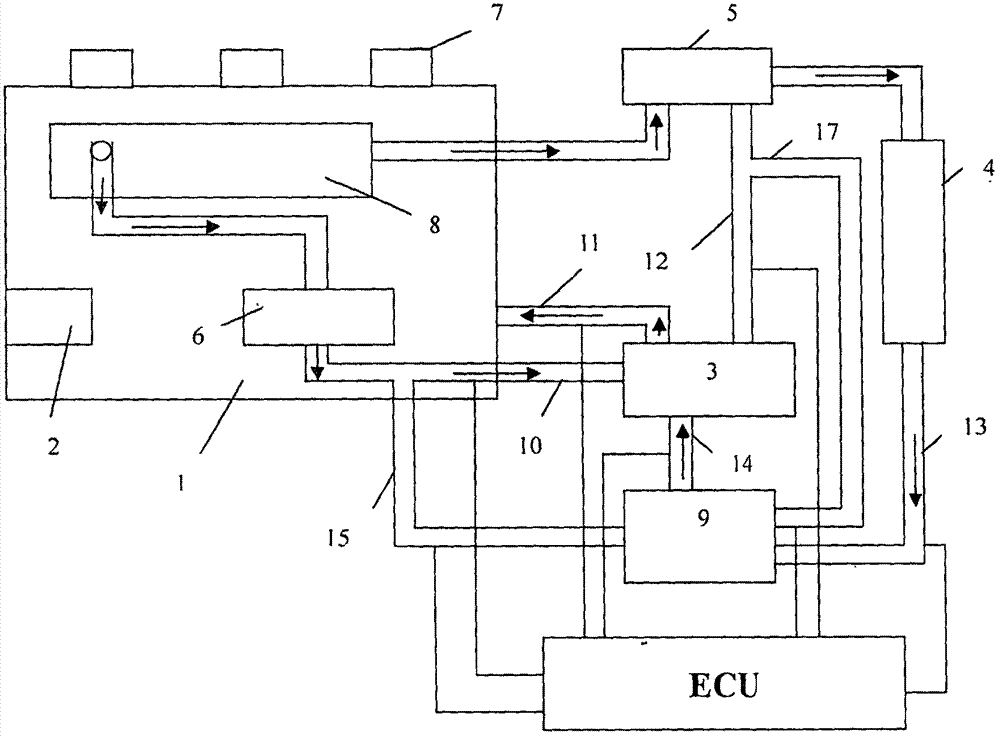

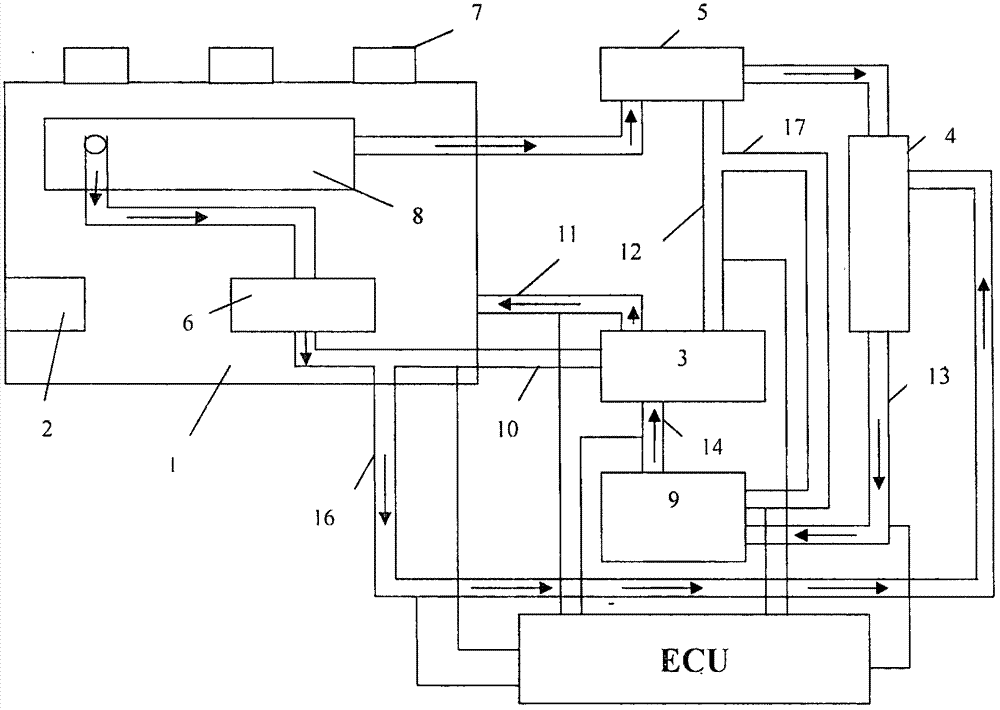

[0034] Figure 1-2 A schematic diagram of the water circulation system of the present invention is shown. Diesel engine body 1 is provided with starter 2, and this starter 2 is an electric motor, and is powered by the vehicle storage battery. The diesel engine 1 includes a cooling water circulation system, which includes a water pump 3, a thermostat 5, a radiator 4, and a conventional water tank 9. The water pump 3 extracts cooling water from the conventional water tank 9, and the internal circulation 8 of the engine body is cooled and passed through The thermostat 5 and the radiator 4 dissipate heat, and enter the water tank again to complete a cooling cycle.

[0035] The water circulation system of the present invention also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com