Round tube type heat tube nest radiator for high power LED cooling

A round-tube, radiator technology, used in lighting and heating equipment, semiconductor devices for light-emitting elements, cooling/heating devices for lighting devices, etc., can solve the problems of inseparability, heavy weight, and low efficiency of metal fin ribs. , to achieve the effect of strong adaptability and enhanced heat pipe performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following embodiments .

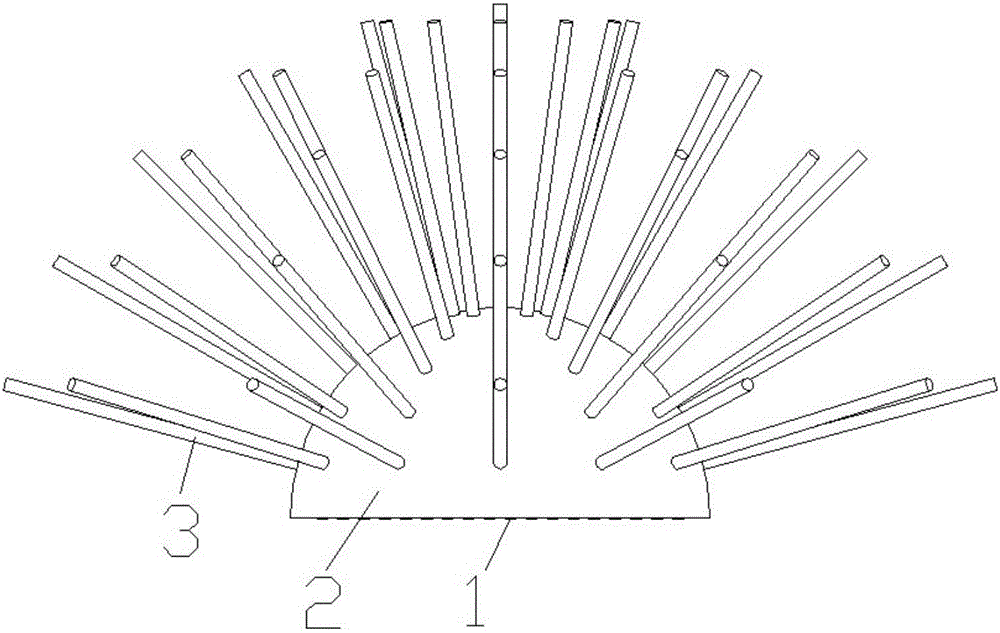

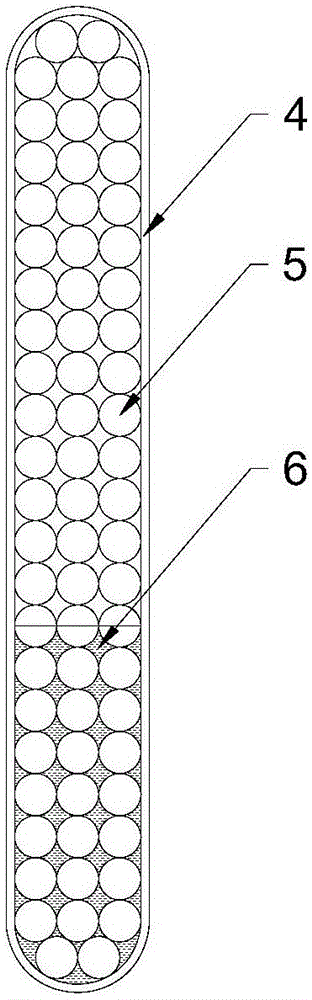

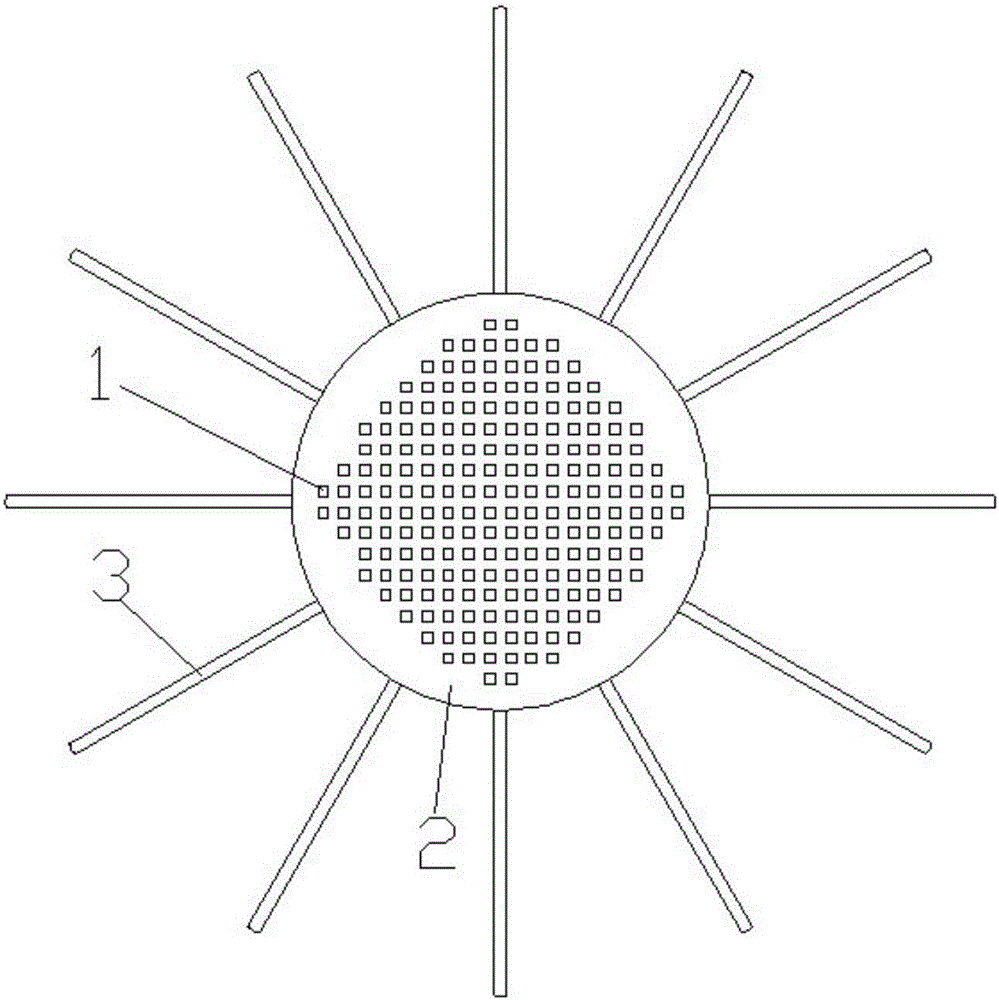

[0025] figure 1 It is the front view of the circular tube type heat pipe group radiator for high-power LED heat dissipation of the present invention, combined with the top view figure 2 ,Bottom view image 3 and central sectional view Figure 4 This embodiment is explained.

[0026] It includes a high-power LED1, a heat conduction block 2 with an LED substrate, and a heat pipe group 3.

[0027] The high-power LED1 is an LED with a power of 200W.

[0028] The heat conduction block 2 with the LED substrate is a hemispherical heat conduction block made of graphite or aluminum, with a diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap