Efficient dual injection type refrigeration system and method thereof

A refrigeration system and jet technology, applied in the fields of refrigeration, air conditioning and heat pump, can solve the problems of increasing the generator, reducing the performance of the heat pump, reducing the thermal coefficient of cooling, etc., to reduce the area and load, improve the thermal performance, reduce the heat effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

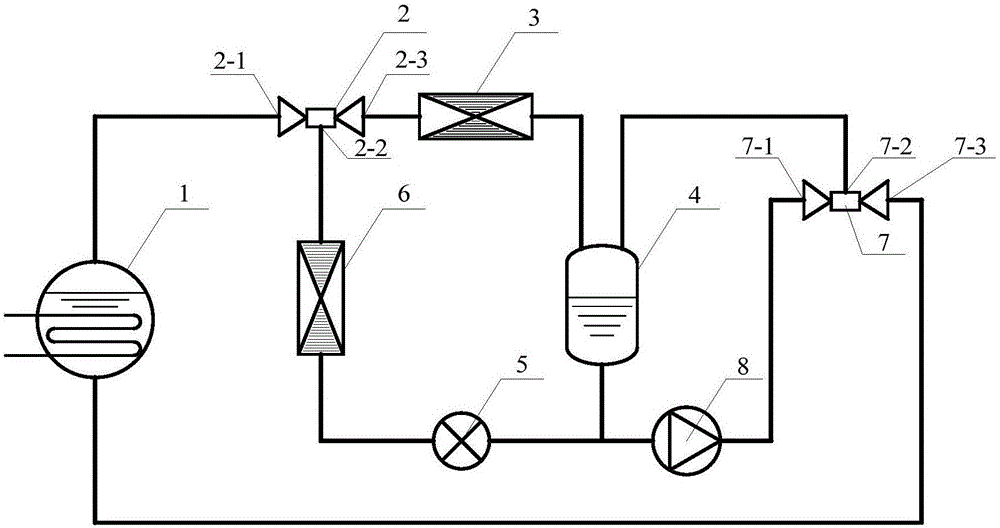

[0017] combine figure 1 , the high-efficiency double-jet refrigeration system of the present invention is provided with a second liquid-gas ejector, which uses high-pressure liquid working fluid to eject the uncondensed gas in the condenser and boosts the pressure, so as to increase the enthalpy value of the working fluid entering the generator and reduce the pressure of the generator. heat load, improving the performance of the ejector refrigeration system. The operating mode of the unit is as follows:

[0018] The condenser 3 is used to incompletely condense the medium-pressure gaseous working medium at the outlet of the main ejector 2, that is, the outlet of the condenser is in a gas-liquid two-phase state, and the gas-liquid two-phase working medium enters the gas-liquid separator or fractionator 4 for phase separation , the separated liquid working medium goes through the throttling mechanism 5 and then enters the evaporator 6 for refrigeration, and the low-pressure gase...

Embodiment 2

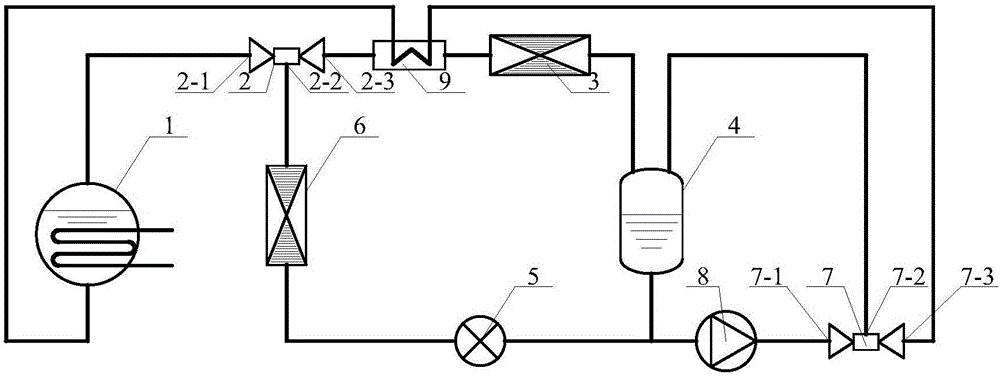

[0020] combine figure 2, the high-efficiency double-jet refrigeration system of the present invention, on the basis of the first scheme, a heat exchanger is arranged between the main ejector and the condenser to further recover the condensation heat and reduce the heat load of the generator, which is beneficial to further improve the efficiency of the jet refrigeration system. Thermal performance. The operating mode of the unit is as follows:

[0021] On the basis of the first scheme, a heat exchanger 9 is arranged between the main injector 2 and the condenser 3, and the gas-liquid two-phase working medium at the outlet of the second liquid-gas injector 7 is exchanged with the steam at the outlet of the main injector 2, Increase the enthalpy of the working fluid entering the generator 1, thereby reducing the load of the generator 1 and improving the performance of the ejector refrigeration system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com