Method for setting calibration block for phased-array ultrasonic testing of bimetal composite material

A composite material and phased array technology, which is applied in the direction of material analysis, measurement device, and material analysis using sonic/ultrasonic/infrasonic waves to ensure welding quality, improve reliability and on-site inspection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

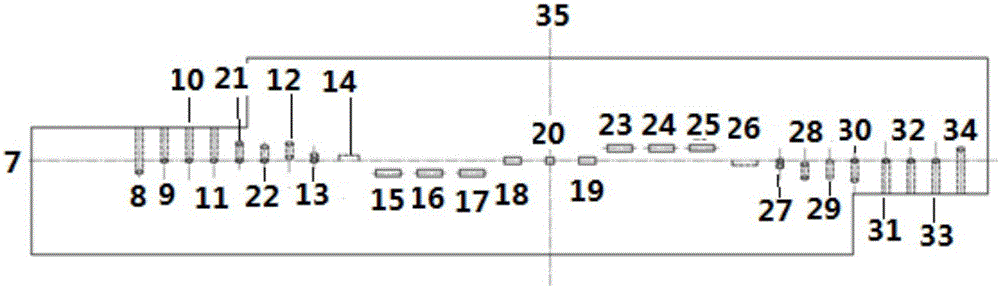

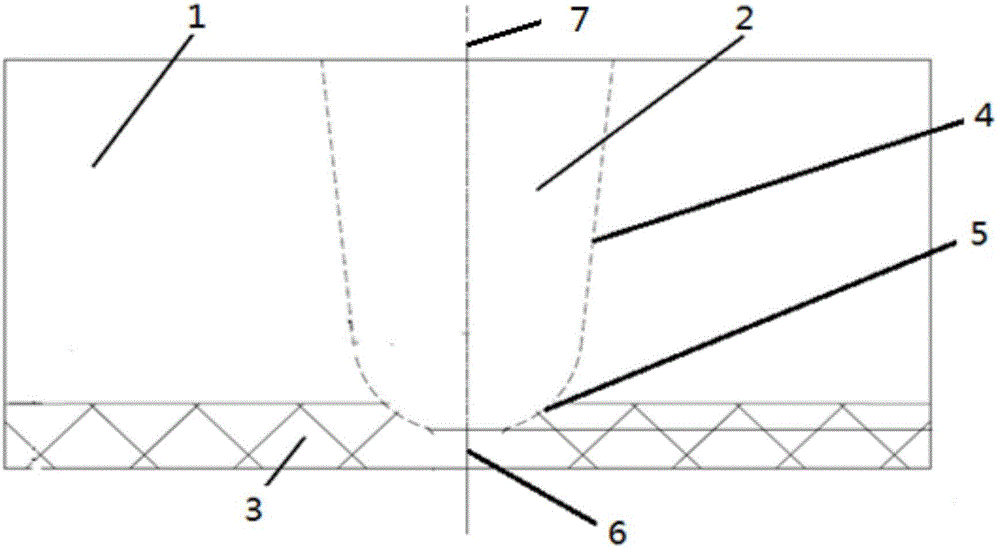

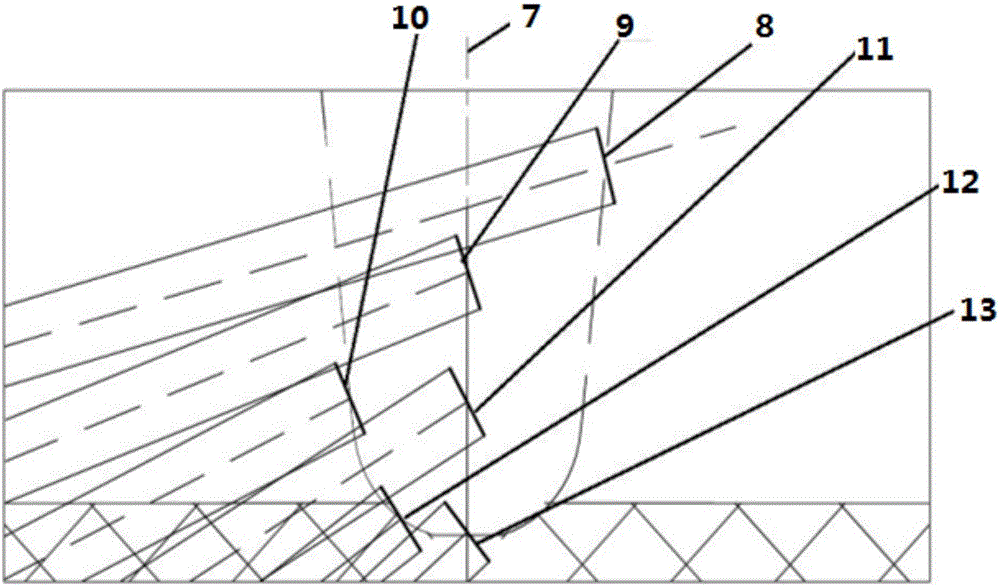

[0032] Such as figure 1 — Image 6 As shown, in this embodiment: the size of the pipeline is 10”x18.9mm, the groove form 4 in the filling area is a J-shaped groove, the base material 1 is made of carbon steel, the anti-corrosion layer 3 at the root is stainless steel with a thickness of 3mm, and the weld filling area 2 is made of nickel base.

[0033] The present invention adopts following specific steps:

[0034] Step 1: Partition the test block according to the groove form 4 of the filling area approved by the welding process, and the height of each partition is 2.5mm, and the root is an independent partition;

[0035] Step 2: According to the combined performance of the phased array probe (AUT) used, set test reflectors at different positions on the groove surface of the filling area, place the probe on the opposite side of the reflector, and select a longitudinal wave test. Move the probe to measure the signal-to-noise ratio of the reflected echo of the test reflector a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com