Mid-set assembly line trolley automatic control system

An automatic control system and automatic control technology, applied in the general control system, control/adjustment system, program control, etc., can solve the problems that the overall operation status of the assembly line cannot be analyzed, problems cannot be responded in time, and employees' rhythm awareness is not strong. , to achieve the expected increase in production capacity, reduce labor intensity, and optimize operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

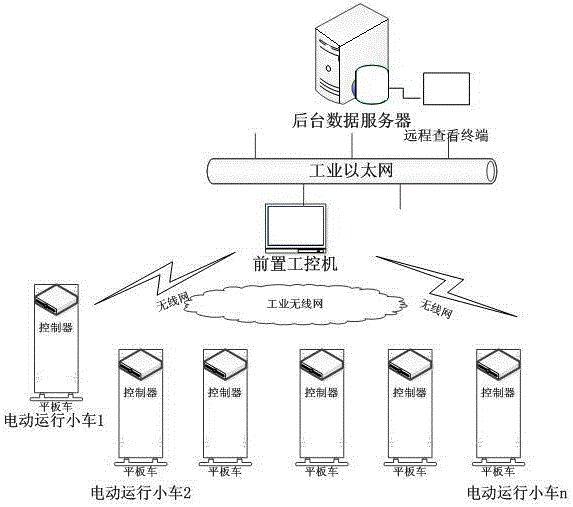

[0021] Such as figure 1 As shown, an automatic control system for a middle-mounted assembly line trolley includes an electric running trolley, a logic control unit, a front-end industrial computer, a background database, a Web report platform, and an automatic control system. The automatic control system includes a trolley travel controller, an industrial Position identification module, alarm light controller and background management host; the automatic control system is driven by a single-chip microcomputer, and the position of the brushless DC motor is controlled. Each control module realizes interconnected distributed control mode through serial communication, and the production line comprehensively applies mechanical technology, sensor application technology, single-chip microcomputer control and networking, brushless DC motor position control and touch screen technology....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com