Anti-ferroelectric-paraelectric material coupled capacitor dielectric and preparation method therefor

An antiferroelectric and capacitor technology, applied in the field of capacitors, can solve problems such as voltage resistance and energy storage efficiency bottlenecks, and achieve the effect of large energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the capacitor dielectric of antiferroelectric-paraelectric material coupling of the present invention, its steps are as follows:

[0024] Step 1: Preparation of antiferroelectric material Pb doped with lanthanum lead zirconate titanate 0.97 La 0.02 (Zr 0.95 Ti 0.05 )O 3 (PLZT) Sol.

[0025] In this embodiment, the molar concentration of the PLZT sol is 0.5 mol / L, and the volume is 100 mL. The preparation raw materials of PLZT sol are shown in Table 1:

[0026] Table 1 Preparation raw materials of PLZT sol

[0027] Drug Name molecular weight Drug purity Experimental ratio stoichiometric number Weighing quality Lead acetate trihydrate 379.33 0.995 1.2 0.97 22.18795g Lanthanum acetate 316.04 0.999 1 0.02 0.31636g zirconium n-propoxide 327.57 0.7 1 0.95 22.2796g Titanium tetraisopropoxide 284.22 0.95 1 0.05 0.74795g

[0028] Concrete preparation steps are as follows:

[0029] 1...

Embodiment 2

[0050] PLZT sol and STO sol are prepared according to step 1 and step 2 described in Example 1. The difference between this embodiment and Example 1 is the spin-coating sequence of step 3. In this embodiment, the STO sol is first spin-coated, and the first The first layer is STO coating, then spin-coated PLZT sol, the second layer is PLZT coating, and then the spin-coating and annealing processes of STO sol and PLZT sol are alternately performed, and the STO coating and PLZT coating are arranged at intervals to obtain antiferroelectric PLZT-paraelectric STO coupling film, that is, a capacitor dielectric coupled with antiferroelectric-paraelectric materials.

Embodiment 3

[0052] The performance of the antiferroelectric PLZT-paraelectric STO coupling film prepared in embodiment 1 and embodiment 2 is characterized below:

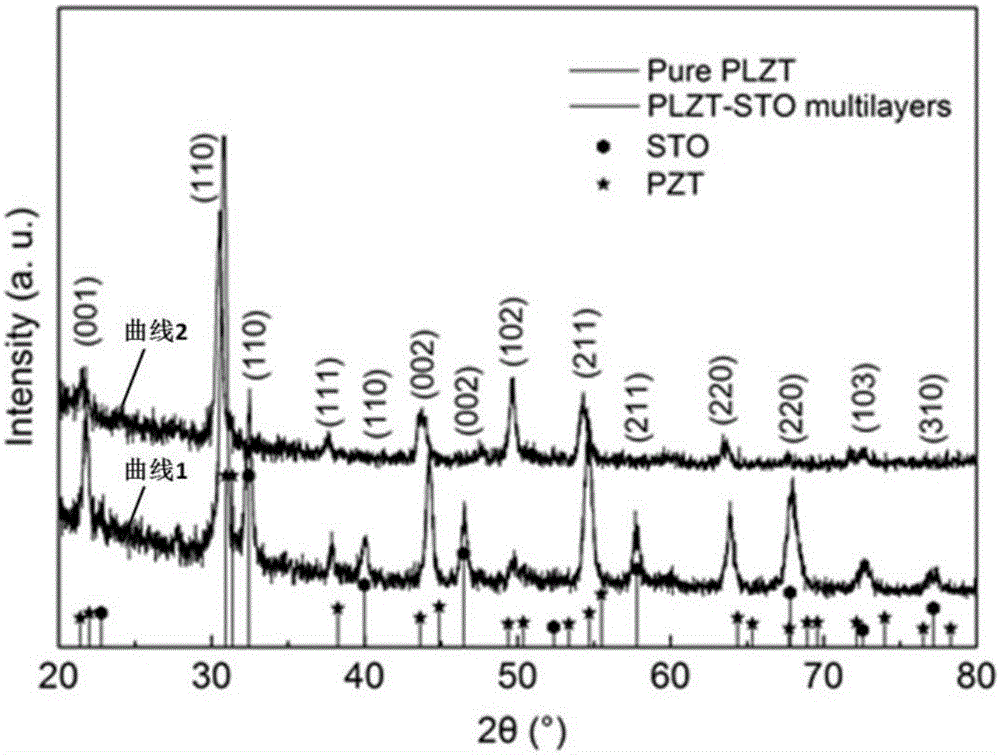

[0053] (1) XRD diffraction comparison chart

[0054] see figure 1 , which is the XRD diffraction diagram of the antiferroelectric PLZT-paraelectric STO coupling film and the pure PLZT film, where curve 1 is the XRD diffraction pattern of the antiferroelectric PLZT-paraelectric STO coupling film, and curve 2 is the pure antiferroelectric PLZT film The XRD diffraction pattern. The test result is obtained by X-ray diffractometer (X'Pert PRO, PANalytical). It can be seen from the figure that the coupled PLZT and STO can form independent phases without any other impurity phases.

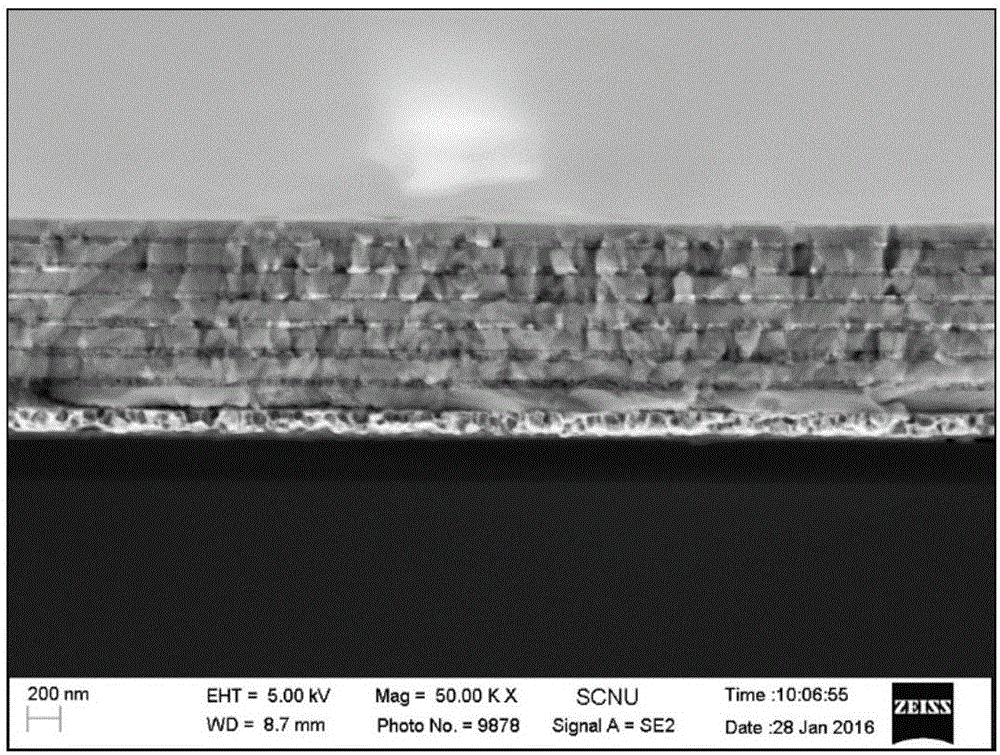

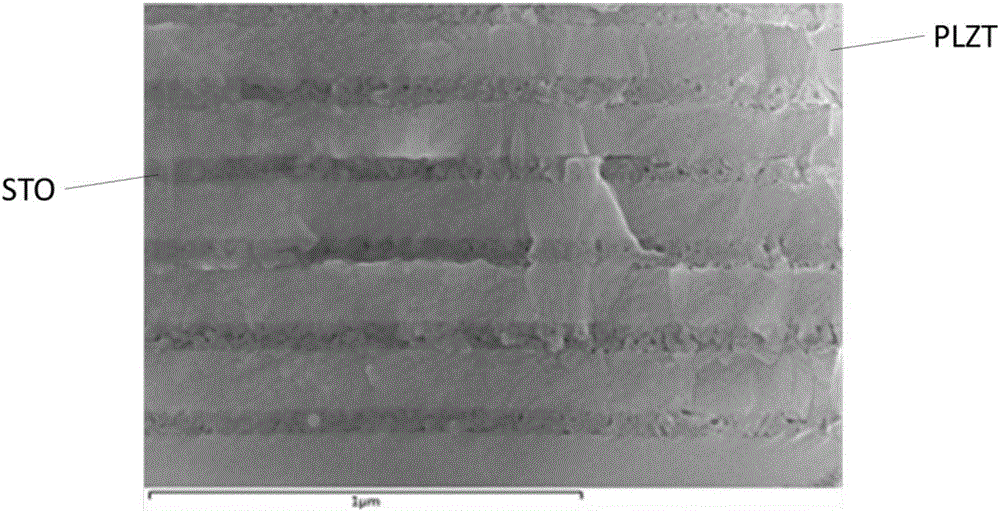

[0055] (2) SEM cross-sectional representation

[0056] Please also see figure 2 and image 3 , figure 2 SEM cross-sectional characterization diagram of antiferroelectric PLZT-paraelectric STO coupling film, image 3 for figure 2 A partial enlar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com