Ga2O3 nerve bionic layer-based nerve bionic device and preparation method thereof

A neural and bionic technology, applied in the direction of electrical components, etc., can solve the problems of poor stability of devices, poor continuity of high and low resistance state conversion, etc., and achieve the effect of good characteristics, high repeatability and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

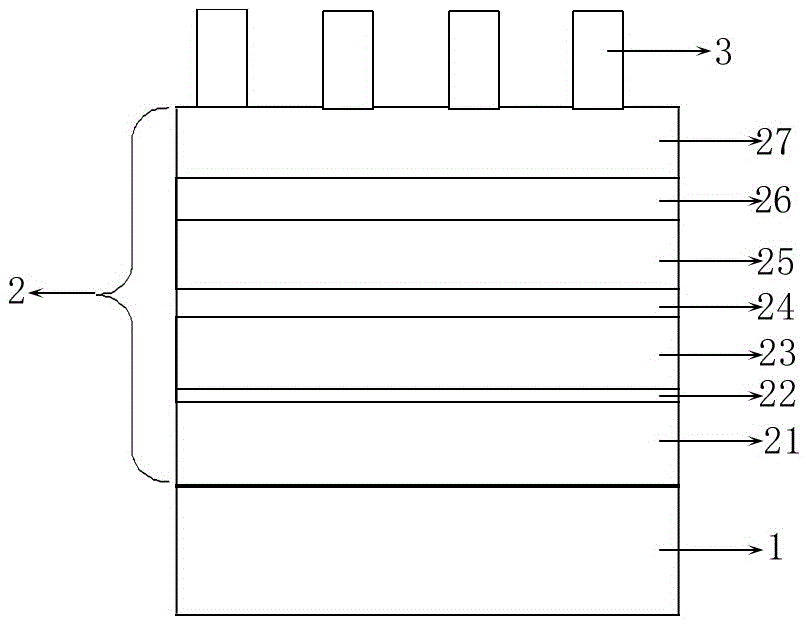

[0036] The neurobionic device provided by the present invention has a structure such as figure 1 shown, including the bottom layer of Pt / Ti / SiO 2 / Si substrate 1, neurobionic layer 2 on the substrate 1, Ag electrode layer 3 on the neurobionic layer 2. Its neurobionic layer 2 is located on the Pt film layer of the substrate 1 .

[0037] Among them, the neurobionic layer 2 is composed of seven layers of film layers stacked in sequence, and from bottom to top is the first Ga layer with a film thickness of 3-7nm. 2 o 3 The film layer 21, the first Ag film layer 22 with a film thickness of 1-3nm, and the second Ga film layer with a film thickness of 3-7nm 2 o 3 The film layer 23, the second Ag film layer 24 with a film thickness of 2-4nm, and the third Ga film with a film thickness of 3-7nm 2 o 3 The film layer 25, the third Ag film layer 26 with a film thickness of 3-5nm, and the fourth Ga film layer with a film thickness of 3-7nm 2 o 3 Membrane 27. The total thickness of...

Embodiment 2

[0040] The preparation method of the neural bionic device provided by the present invention comprises the following steps:

[0041] 1. Forming a neurobionic layer on a substrate

[0042] (1) Prepare the substrate

[0043] Choose Pt / Ti / SiO 2 / Si as the substrate, then Pt / Ti / SiO 2 / Si substrate is placed in acetone and ultrasonically cleaned for 10 minutes, then placed in alcohol and ultrasonically cleaned for 10 minutes, then taken out with clips, placed in deionized water and ultrasonically cleaned for 5 minutes, finally taken out, and cleaned with N 2 blow dry.

[0044] (2) Put the substrate into the chamber and evacuate it

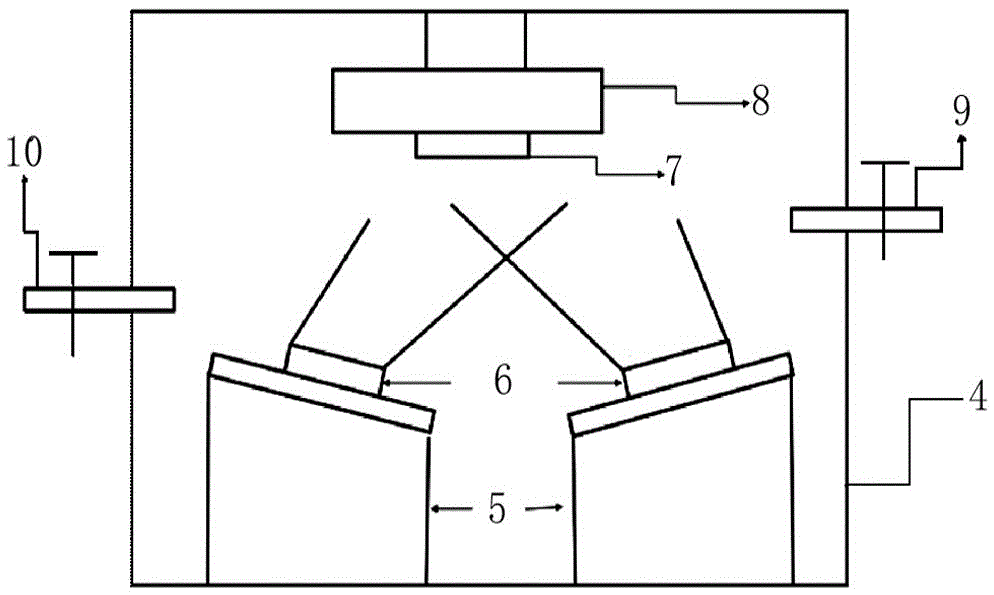

[0045] use as figure 2 For the magnetron sputtering equipment shown, open the chamber 4 of the magnetron sputtering equipment, take out the tablet press table 7, polish it with sandpaper to remove surface stains, clean the polished waste and organic matter attached to the surface with acetone, and finally wipe it with alcohol clean. The cleaned P...

Embodiment 3

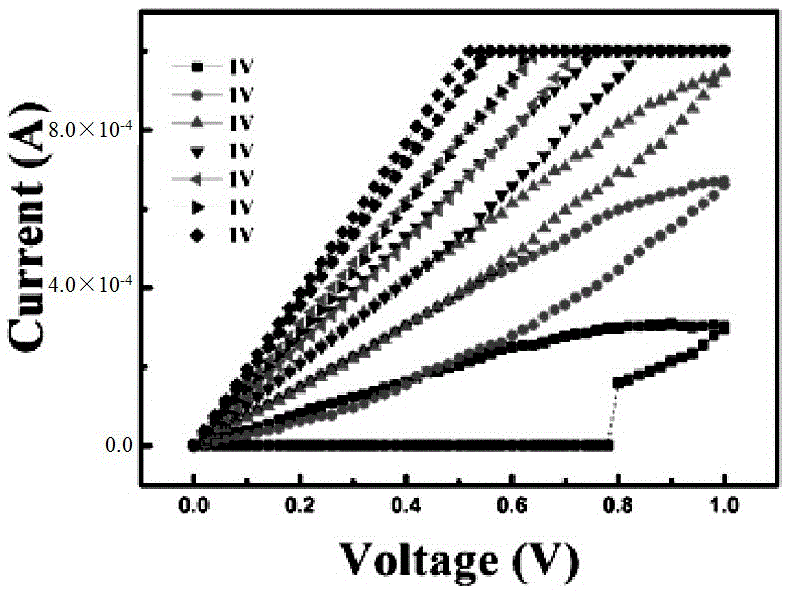

[0069] The neurobionic device prepared in Example 2 was scanned by applying seven positive voltages of 0-1-0V successively, and the results were as follows: image 3 shown. When seven voltage scans of 0-1-0V are applied sequentially to the Ag electrode layer of the neurobionic device prepared in Example 2, when the first voltage scan is applied, when the voltage reaches 0.8v, the resistance of the neurobionic device begins Changes occur, and a steady state can occur. By continuously applying the scanning voltage, the bionic device can realize the memory function, that is, the starting resistance value of a new scanning is the end resistance value of the previous scanning.

[0070] Seven different negative voltages were applied sequentially to the neurobionic device prepared in Example 2 to scan, and the results were as follows: Figure 4 shown. When seven different negative voltage scans are applied to the Ag electrode layer of the neurobionic device prepared in Example 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com