Liquid metal magnetohydrodynamic power generation system driven by single-stage loop traveling wave thermoacoustic engine

A technology of magnetic fluid power generation and thermoacoustic engine, which is applied in the direction of hot gas variable displacement engine device, machine/engine, Stirling engine, etc. Loss and other issues, to meet the needs of power transmission and electrical equipment, flexible power, stable conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

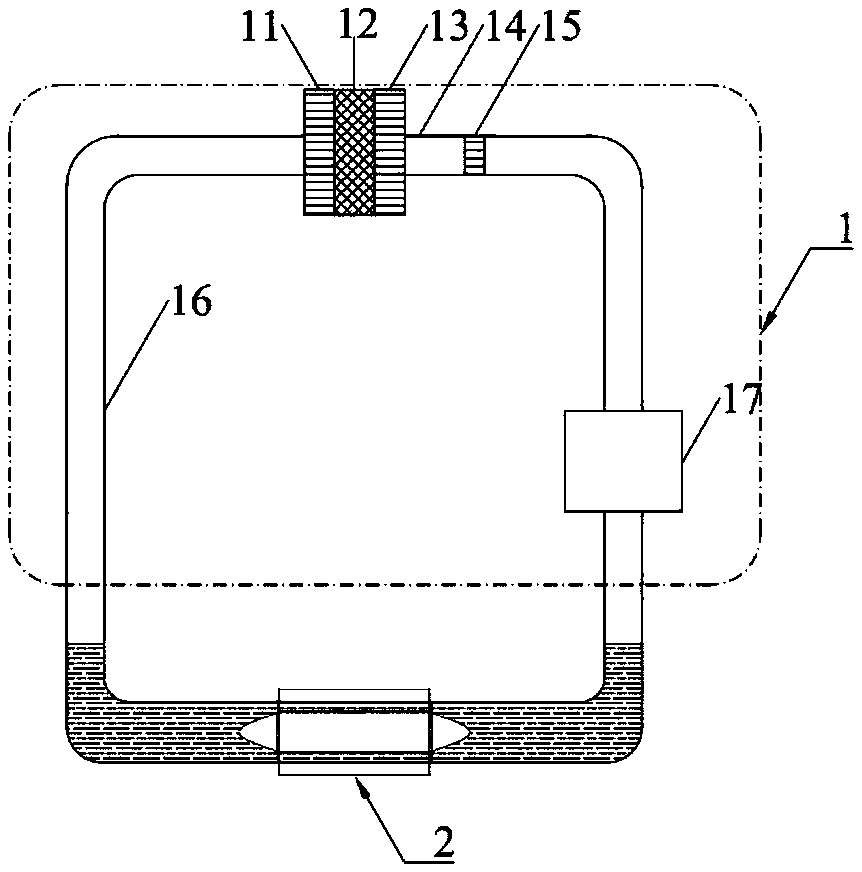

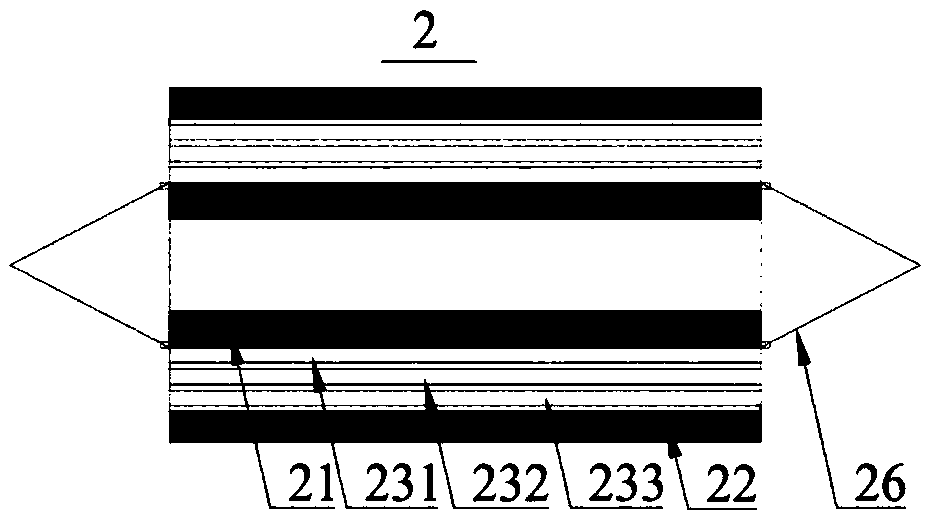

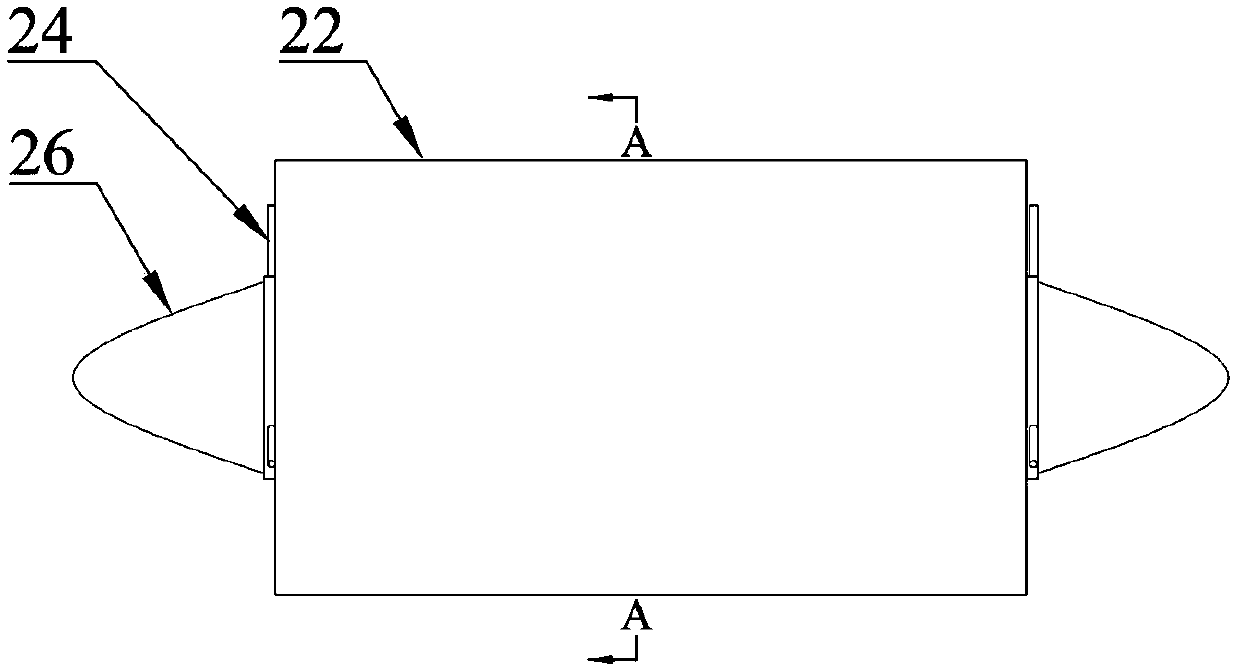

[0028] In the liquid metal magnetic fluid power generation system driven by a single-stage loop traveling wave thermoacoustic engine of the present invention, the liquid metal magnetic fluid generator is coupled to the resonance tube of the single-stage loop traveling wave thermoacoustic engine that uses the cavity as a phase modulation method. The thermoacoustic effect converts the thermal energy of the external heat source into the sound energy (mechanical energy) of the reciprocating oscillation of the working gas. The reciprocating oscillation of the gas pushes the liquid metal in the multi-layer annular channel to reciprocate in the magnetic field. The liquid metal cuts the magnetic force line to generate an induced electromotive force. The plate electrodes in adjacent power generation channels are connected in series with each other through wires, which increases the total output voltage and total internal resistance of the liquid metal magnetic fluid generator, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com