A method for converting natural gas into synthetic gas

A natural gas and conversion gas technology, applied in the field of natural gas conversion to produce synthetic gas, can solve the problems of high consumption of natural gas, large investment in equipment, difficult industrial application, etc., and achieve the effect of large-scale conversion, low energy consumption and increased content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

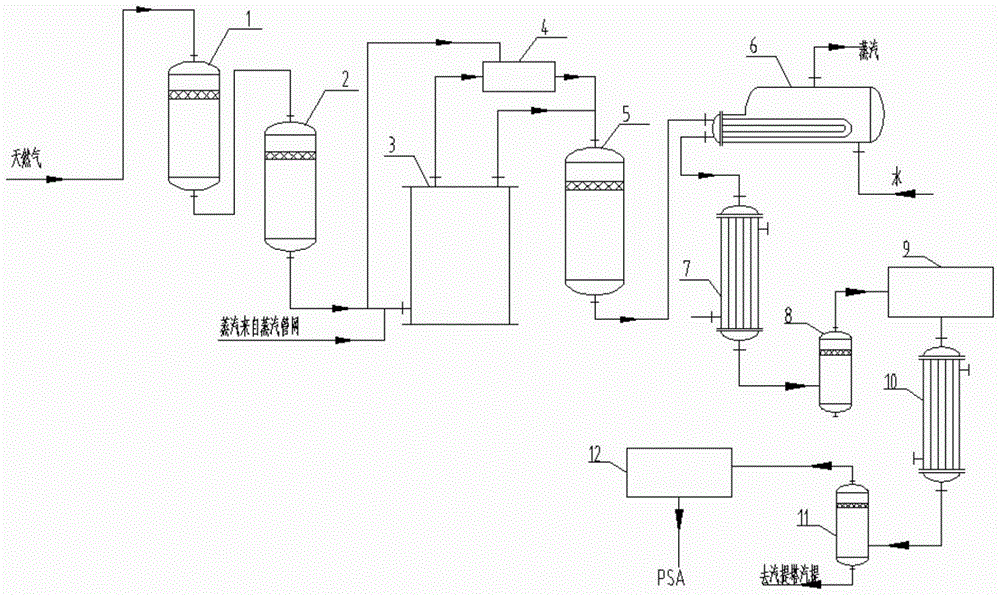

[0045] as attached figure 1 As shown, the natural gas from the boundary area enters the hydroconverter 1 and the zinc oxide desulfurization tank 2 in order to remove hydrogen sulfide and organic sulfide in the natural gas. The desulfurized natural gas is mixed with the first water vapor to form the first mixed gas at 530° C. and 3.8 MPa, and the volume ratio of the first water vapor to natural gas is 3.5:1. The first mixed gas is heated to about 505°C through the mixed feed gas coil in the convection section of the primary reformer 3, and then enters the furnace tubes of the primary reformer 3 (the furnace tubes are divided into nine rows, 42 tubes in each row). The steam reforming of hydrocarbons is carried out under the action of a catalyst to generate a reformed gas. The steam reforming reaction of hydrocarbons is an endothermic reaction, and the heat required for the first-stage reforming reaction is supplied by the burner at the top of the radiant section of the first-st...

Embodiment 2

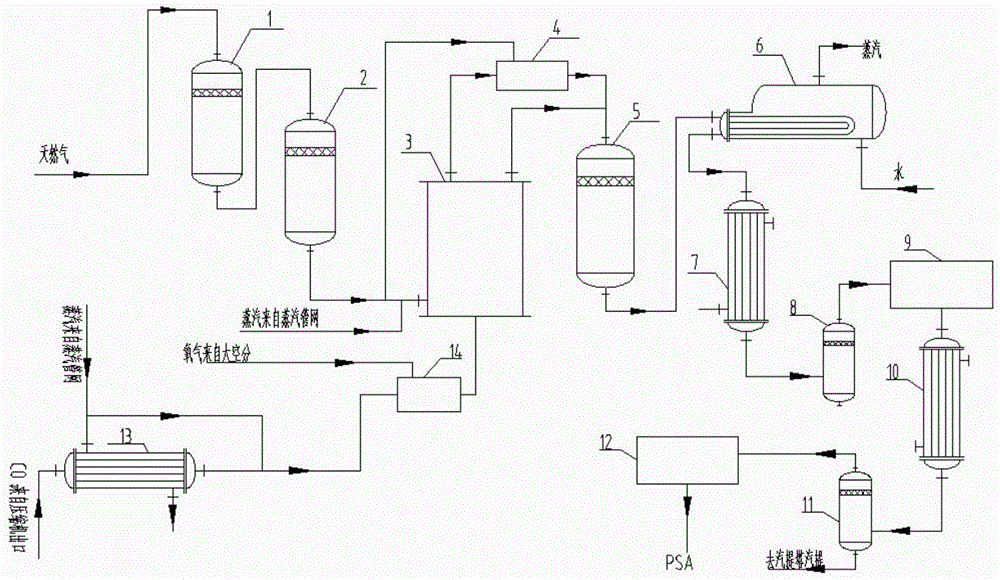

[0049] The natural gas from the boundary area enters the hydroconverter 1 and the zinc oxide desulfurization tank 2 in order to remove hydrogen sulfide and organic sulfide in the natural gas. The desulfurized natural gas is mixed with the first water vapor to form the first mixed gas with a temperature of 550°C and a pressure of 4.0 MPa, wherein the volume ratio of the first water vapor to natural gas is 2:1.

[0050] After the carbon dioxide from the outlet of the carbon dioxide compressor exchanges heat with the medium-pressure steam in the heat exchanger 13, it is mixed with the second water vapor and pure oxygen (25°C, 4.6MPa) from the large air separation in the mixer 14 to form The second mixed gas, so that the volume ratio of the second water vapor, carbon dioxide and oxygen in the second mixed gas is 1:0.7:1.4.

[0051] The second mixed gas and the first mixed gas are simultaneously sent to the preheating section of the primary reformer 3 for reaction to generate a pri...

Embodiment 3

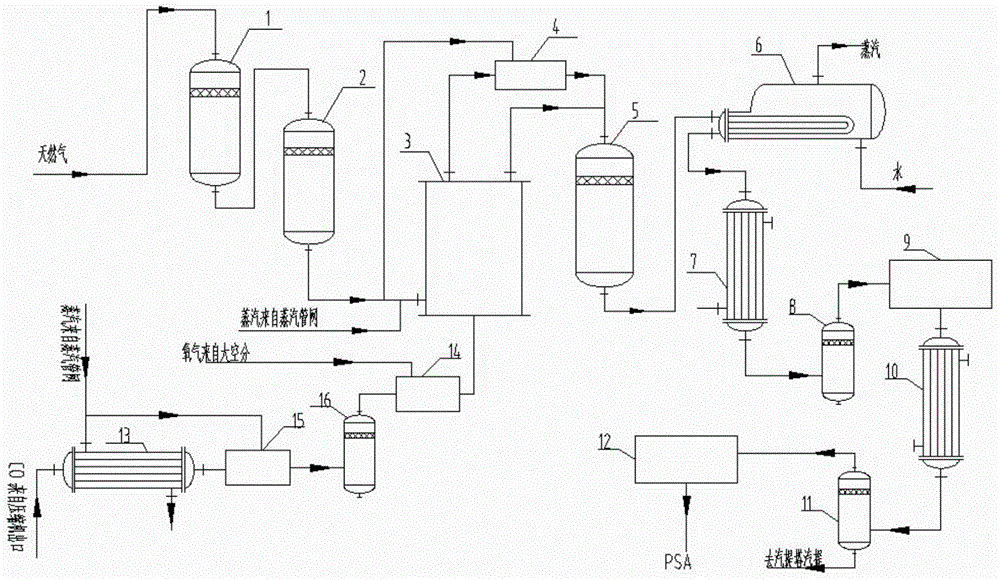

[0055] The natural gas from the boundary area enters the hydroconverter 1 and the zinc oxide desulfurization tank 2 in order to remove hydrogen sulfide and organic sulfide in the natural gas. The desulfurized natural gas is blended into the first mixed gas with the formation temperature of the first water vapor at 510°C and a pressure of 3.5 MPa, wherein the volume ratio of the first water vapor to natural gas is 2:1.

[0056] After the carbon dioxide from the outlet of the carbon dioxide compressor exchanges heat with the medium-pressure steam in the heat exchanger 13, it mixes with the second water vapor in the mixer 15 to form a third mixed gas. The temperature of the second steam is 273° C. and the pressure is 3.5 MPa. The carbon-hydrogen ratio is adjusted so that the molar ratio of carbon dioxide to the second water vapor in the third mixed gas is 1:3. The third mixed gas with a qualified carbon-hydrogen ratio passes through the filter 16 to filter out impurities and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com