Equipment for cleaning recovered aluminium alloy

An aluminum alloy and equipment technology, which is applied in the field of equipment for cleaning and recycling aluminum alloys, can solve the problems of inability to clean the surface of the aluminum alloy, difficult to discharge, and the aluminum alloy is mixed, and achieves the effects of simple structure, reduced waste, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

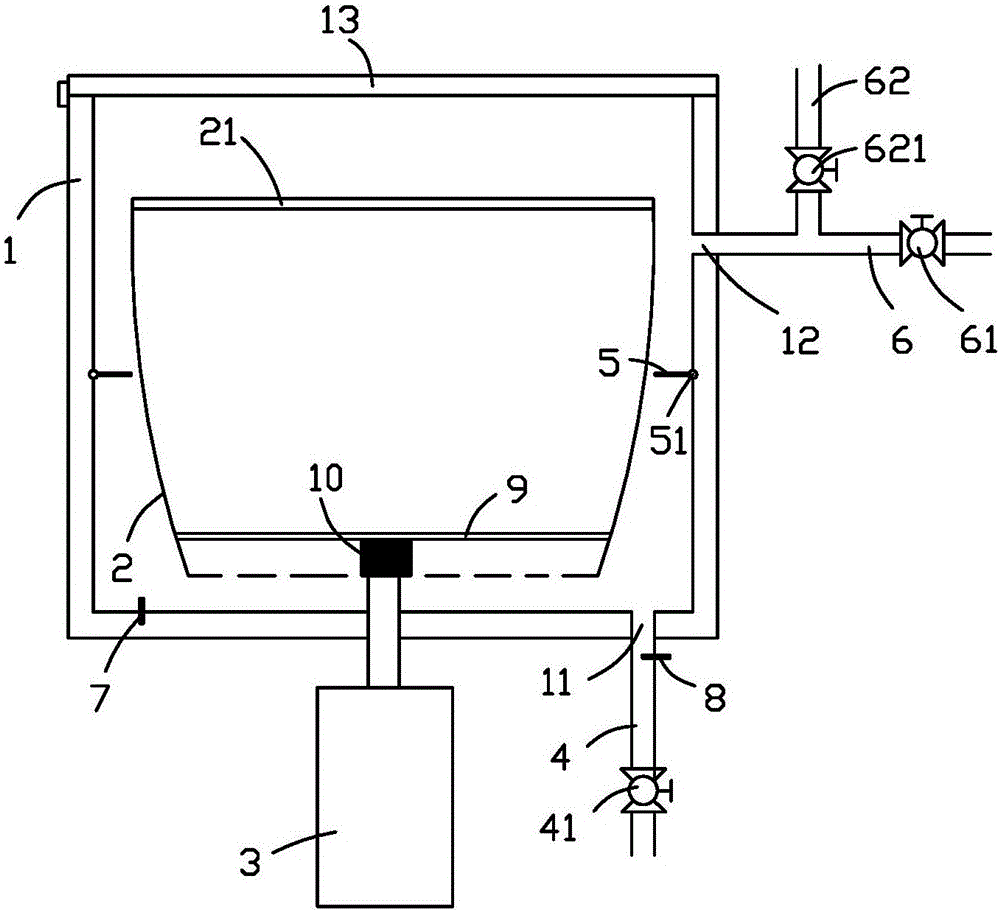

[0023] see figure 1 , In a preferred embodiment of the present invention, a device for cleaning and recycling aluminum alloys includes a first accommodating device 1 , a second accommodating device 2 and a centrifugal motor 3 . The first accommodating device 1 has a side wall and a bottom wall, and a sewage discharge port 11 is opened on it. A sewage discharge pipe 4 is installed at the sewage discharge port 11, and a sewage discharge valve 41 is installed on the sewage discharge pipe 4 . The second accommodating device 2 is accommodated in the first accommodating device 1, and is located above the bottom wall of the first accommodating device 1, and the bottom and the upper part are spaced apart to provide a plurality of passages for communicating the inside and outside of the second accommodating device 2. hole. The inner side wall of the first storage device 1 is horizontally provided with a grid-shaped connection plate 5, the connection plate 5 is rotatably connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com