Production method of micro-sphere foaming ice flower decorative material for building interiors

A technology for microsphere foaming and decoration materials, applied in the field of building interior decoration materials, can solve problems such as difficulty in achieving a balance between decoration grade and price cost, insufficient antibacterial and antifungal properties, and increase power cost, etc. The effect of interior grade and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

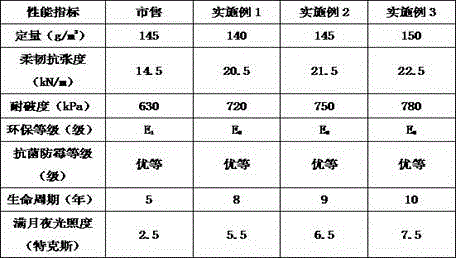

Examples

Embodiment 1

[0044] A production method of microsphere foamed ice flower decoration material for building interior decoration in commercial places, the processing steps are as follows:

[0045] (1) Production of base paper: Taking natural 4wt% silver-containing antibacterial softwood fiber material as raw material, wet papermaking base paper with no aspect difference on a water filter cartridge paper machine, wherein the base paper basis weight is 100g / m 2 ;

[0046] (2) Silk processing: antibacterial silver silk and waxy cotton silk are used as raw materials to form a silk fabric with a houndstooth pattern using the Soviet embroidery technique, in which the weight of the antibacterial silver silk is 4wt%;

[0047] (3) Adhesion: Use natural glue made from seaweed to bond the silk fabric in step (2) to the surface of the base paper in step (1) to form a basis weight of 120g / m 2 The substrate layer;

[0048] (4) Application and microsphere foaming: apply the microsphere foam material to the surface o...

Embodiment 2

[0055] A production method of microsphere foamed ice flower decoration material for building interior decoration in commercial places, the processing steps are as follows:

[0056] (1) Production of base paper: Using 4wt% antibacterial softwood fiber material with natural silver content as raw material, the base paper with no aspect difference is made by wet method on the water filter cylinder paper machine, and the base paper weight is 105g / m 2 ;

[0057] (2) Silk processing: use antibacterial silver silk and waxy cotton silk as raw materials to form a silk fabric with a houndstooth pattern using the Soviet embroidery technique, in which the weight of antibacterial silver silk is 7wt%;

[0058] (3) Adhesion: Use natural glue made from seaweed to bond the silk fabric in step (2) to the surface of the base paper in step (1) to form a basis weight of 125g / m 2 The substrate layer;

[0059] (4) Application and microsphere foaming: apply the microsphere foam material to the surface of the s...

Embodiment 3

[0066] A production method of microsphere foamed ice flower decoration material for building interior decoration in commercial places, the processing steps are as follows:

[0067] (1) Production of base paper: Using 4wt% antibacterial softwood fiber material with natural silver content as raw material, the base paper with no aspect difference is made by wet method on the water filter cylinder paper machine, and the base paper weight is 110g / m 2 ;

[0068] (2) Silk processing: The antibacterial silver silk and waxy cotton silk are used as raw materials to form a silk fabric with a houndstooth pattern using the Soviet embroidery technique, in which the weight of the antibacterial silver silk is 10wt%;

[0069] (3) Adhesion: Use natural glue made from seaweed to bond the silk fabric in step (2) to the surface of the base paper in step (1) to form a basis weight of 130g / m 2 The substrate layer;

[0070] (4) Application and microsphere foaming: apply the microsphere foam material to the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com