A kind of zirconium dioxide mesoscopic crystal and its preparation method and application

A technology of zirconia mesoscopic and zirconium oxychloride, which is applied in the fields of zirconia, chemical instruments and methods, bulk chemical production, etc., can solve the problems such as public reports of zirconia mesoscopic crystal preparation technology, and achieve excellent production Hydrogen catalytic performance, high yield, and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 9.02 g of zirconium oxychloride in 50 mL of deionized water, calibrate the above solution to 70 mL with deionized water, and then transfer it to a high-temperature reactor with a volume of 100 mL (that is, the molar concentration of zirconium oxychloride is 0.4 mol / L , the molar ratio of cetyltrimethylammonium bromide to zirconium oxychloride is 0:1). The reaction kettle was put into a blast drying oven, the reaction temperature was controlled at 150 °C, and the reaction time was 6 h. The obtained product was washed by centrifugation to remove impurity ions and then dried at 60 °C for 8 h to obtain ZrO 2 mesoscopic crystals.

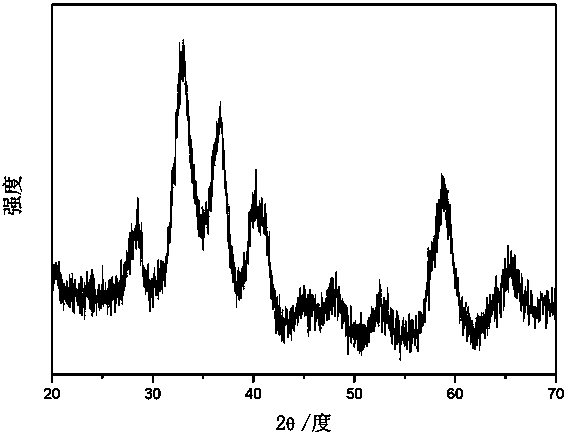

[0025] figure 1 It is the XRD figure of the zirconia mesoscopic crystal prepared in the present embodiment. Depend on figure 1 It can be seen that the prepared ZrO 2 Was monoclinic phase.

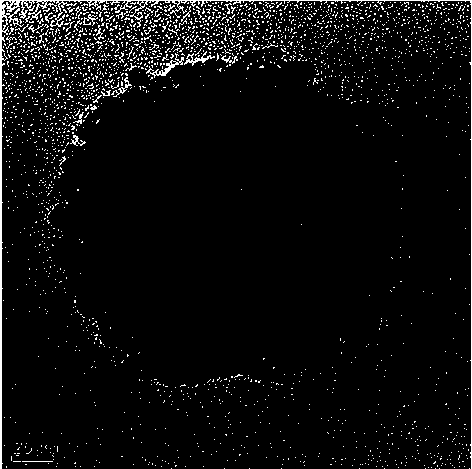

[0026] figure 2 , image 3 These are the SEM images and TEM images of the zirconia mesoscopic crystals prepared in this example, respectively...

Embodiment 2

[0030] Dissolve 4.59 g of cetyltrimethylammonium bromide and 10.15 g of zirconium oxychloride in 50 mL of deionized water to prepare a mixed solution. The above mixed solution is calibrated to 70 mL with deionized water and then transferred to a volume of 100 mL of high-temperature reactor (that is, the molar concentration of zirconium oxychloride is 0.45 mol / L, and the molar ratio of cetyltrimethylammonium bromide to zirconium oxychloride is 0.4:1). The reaction kettle was put into a blast drying oven, the reaction temperature was controlled at 145 °C, and the reaction time was 8 h. The obtained product was washed by centrifugation to remove impurity ions and then dried at 60 °C for 8 h to obtain ZrO 2 mesoscopic crystals.

[0031] Figure 5 SEM image of zirconia mesoscopic crystals prepared for this example. Figure 5 shows that the prepared ZrO 2 The particles are also nano-disc-like mesoscopic crystals.

[0032] N 2 -Physical adsorption and desorption experiments sho...

Embodiment 3

[0034] Dissolve 2.55 g of cetyltrimethylammonium bromide and 11.28 g of zirconium oxychloride in 50 mL of deionized water to prepare a mixed solution. The above mixed solution is calibrated to 70 mL with deionized water and then transferred to a volume of 100 mL of high-temperature reactor (that is, the molar concentration of zirconium oxychloride is 0.5 mol / L, and the molar ratio of cetyltrimethylammonium bromide to zirconium oxychloride is 0.2:1). The reaction kettle was put into a blast drying oven, the reaction temperature was controlled at 155 °C, and the reaction time was 5 h. The obtained product was washed by centrifugation to remove impurity ions and then dried at 60 °C for 8 h to obtain ZrO 2 mesoscopic crystals.

[0035] Figure 6 SEM image of zirconia mesoscopic crystals prepared for this example. Figure 6 shows that the prepared ZrO 2 The particles are also nano-disc-like mesoscopic crystals.

[0036] N 2 -Physical adsorption and desorption experiments show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com